6 option 6 – linear calibration – Rice Lake Condec UMC600 User Manual

Page 35

32

UMC600 Installation Manual

ID HELD

This function is enabled when 5.3 is selected On. When ID held is enabled, the current keyed in ID number is stored

in memory and is sent out with each valid demand serial print. There are two methods of ID entry.

•

Gross/Net mode – use numeric keys to enter the desired ID number, then press

.

•

Gross mode only – key in numeric value and press

ENTER

. This stores the new ID number for the next

print command.

NOTE: Leading zero entry not allowed.

NOTE: If a zero value is entered as an ID number, there is no printout of an ID number.

Counter

The counter feature is a six digit counter that sequentially increments by one on each valid print command in the net

mode only. It is enabled when 5.4 is on and has a range from 0 - 999,999.

4.6

Option 6 – Linear Calibration

There are five calibration points that can be entered sequentially. Calibrations using fewer than five points will

linearize the curve up to the last data point.

Enabling option 6 places the indicator in a linearization calibration when the unit is in the calibration mode (SW1-1

closed on front panel DIP switch). Use the five-point linearization procedure outlined in Section 5.3 on page 48 to

perform a scale calibration when option 6 is enabled.

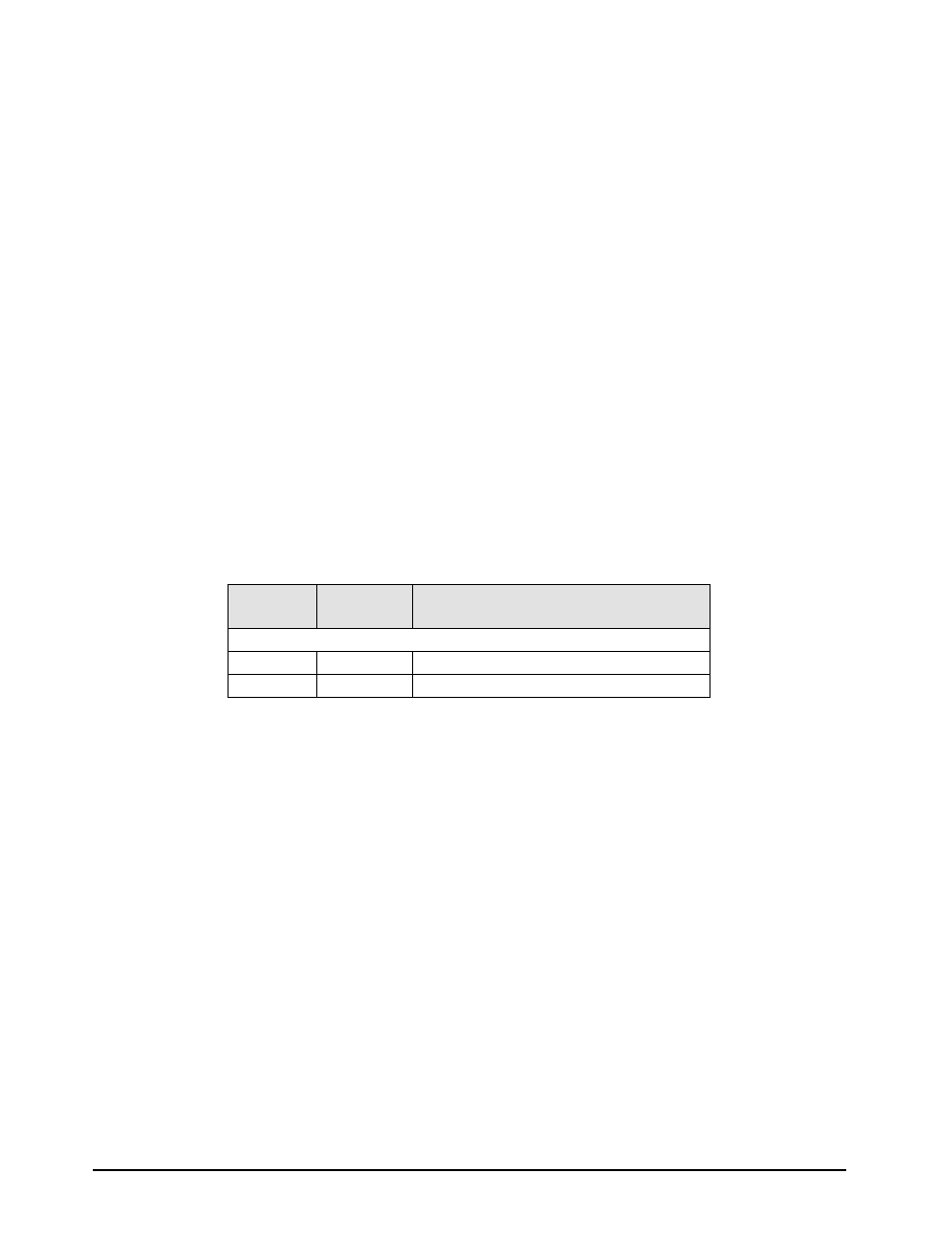

The five-point linearization calibration (OP.6) is shown in Table 4-9

.

Table 4-9. Option 6 Configuration Selections

Refer to Section 4.12.3 on page 46 for individual serial command option parameters for Option 6.

Prompt

Display

Interpretation

Notes

Five-point linearization

OP.6

oFF

Off

—

OP.6

on

On

Enter up to five linearization points