4 replacement of o-ring, 5 stopping and re-starting operation, 1 replacing fuses -9 11.2.2 cleaning -10 – Yokogawa Single Channel Oxygen Analyzer System ZR22/ZR402 User Manual

Page 180: Caution

IM 11M12A01-03E

11-8

11.1.4

Replacement of O-ring

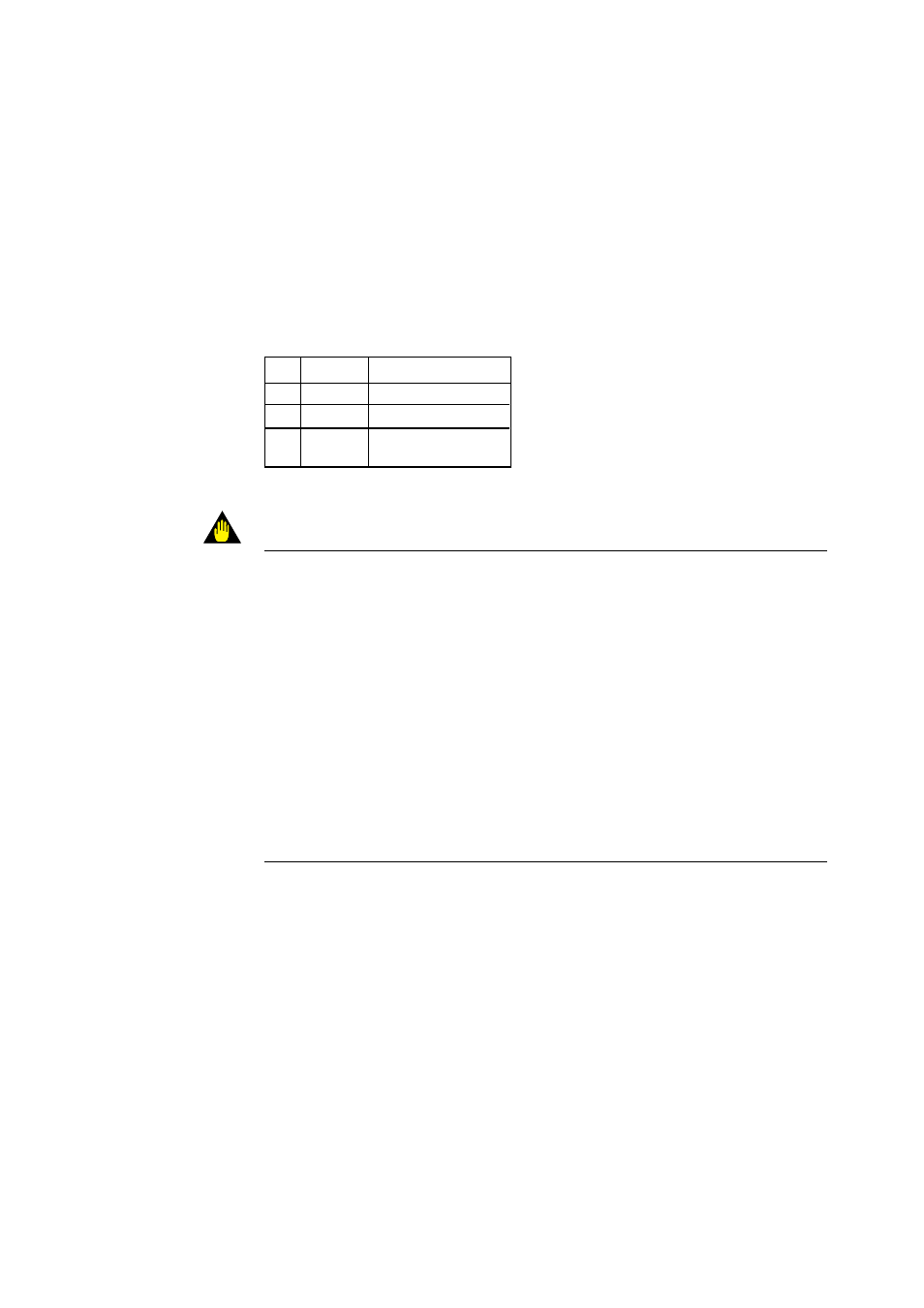

The detector uses three different types of O-rings (14), (21), and (22). One O-ring alone

(14), or two O-rings (21) and (22) are used. (For a pressure-compensating model, two O-

rings are used for individual uses. Two O-rings (21) and (22) are used for reference-gas

sealing and require periodic replacement.

11.1.5 Stopping and Re-starting Operation

When operation is stopped, take care of the followings so that the sensor of the detector

cannot become unused.

T11.1.5E.ES

Part No.

Description

(7) K9470BJ

Metal ring

(14) K9470ZS

Metal ring with grease

(21)

Two pairs of O-rings

(22)

with grease

K9470ZP

CAUTION

When operating an instrument such as boiler or industrial furnace is stopped with the

zirconia oxygen analyzer operation, moisture can condensate on the sensor portion and

dusts may stick to it.

If operation is restarted in this condition, the sensor which is heated up to 750

ЊC firmly

fix the dusts on itself. Consequently, the dusts can make the sensor performance very

lower. If a large amount of water is condensed, the sensor can be broken and never re-

useful.

To prevent the above nonconformity, take the following action when stopping operation.

(1) If possible, keep on supplying the power to converter and flowing reference air to

the sensor.

If impossible to do the above, remove the detector.

(2) If unavoidably impossible to supply the power and removing the detector, keep on

following air at 600ml/min into the calibration gas pipe.

When restarting operation, be sure to flow air, for 5-10 minutes, at 600ml/min into the

calibration gas pipe before supplying the power to converter.