3 compensation, Calibration procedures -6 – Yokogawa Single Channel Oxygen Analyzer System ZR22/ZR402 User Manual

Page 140

IM 11M12A01-03E

9-4

9.1.3

Compensation

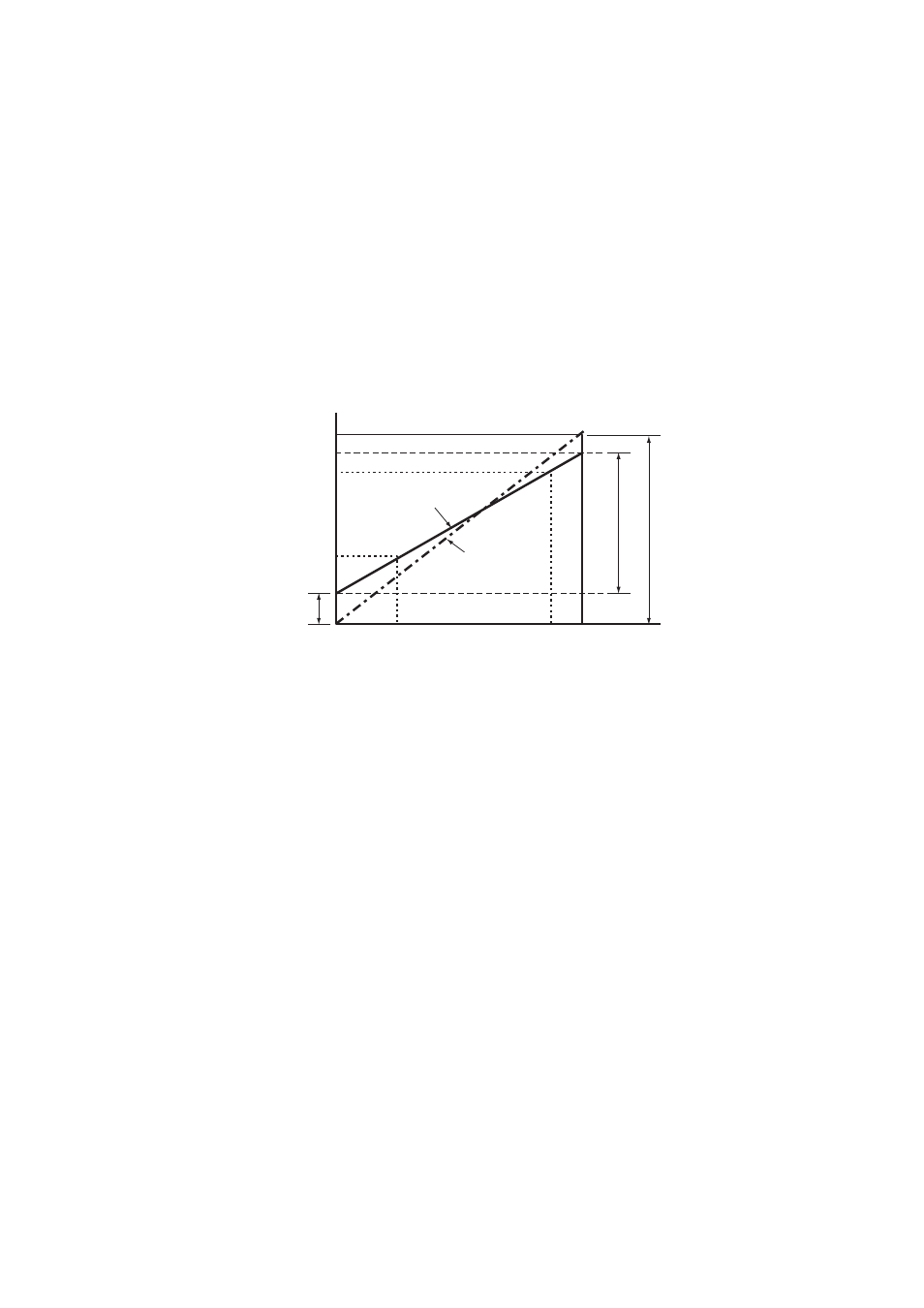

The deviation of a measured value from the theoretical cell electromotive force is

checked by the method in Figure 9.1 or 9.2.

Figure 9.1 shows a two-point calibration using two gases: zero and span. Cell electromo-

tive forces for a span gas with an oxygen concentration p1 and a zero gas with an

oxygen concentration p2 are measured while determining the calibration curve passing

between these two points. The oxygen concentration of the measurement gas is deter-

mined from this calibration curve. In addition, the calibration curve corrected by

calibration is compared with the theoretical calibration curve for determining the zero-

point correction ratio represented by B/A

ϫ100 (%) on the basis of A, B and C shown in

Figure 9.2 and a span correction ratio of C/A

ϫ100 (%). If the zero-point correction ratio

exceeds the range of 100

Ϯ30 % or the span correction ratio becomes larger than 0Ϯ18

%, calibration of the sensor becomes impossible.

21.0

p1

p2

0.51

81.92

ez

e2

e1

es

0

C

A

B

Zero-point correction factor = (B/A) x 100 (%) Correctable range: 100

±

30%

Span correction factor = (C/A) x 100 (%) Correctable range: 0

±

18%

Cell

electromotive

force, mV

Calibration curve

before correction

Corrected calibration

curve (theoretical

calibration curve)

Zero origin

Span-gas concentration

Zero-gas concentration

Span origin

Oxygen concentration (vol%O

2

)

F9.2E.EPS

Figure 9.2 Calculation of a Two-point Calibration Curve and Correction Factors

using Zero and Span Gases