1 < exaxt zr > system configuration, 1 system 1, Exaxt zr > system configuration -2 – Yokogawa Single Channel Oxygen Analyzer System ZR22/ZR402 User Manual

Page 15: System 1 -2, Caution

IM 11M12A01-03E

1-2

1.1

< EXAxt ZR > System Configuration

The system configuration should be determined by the conditions; e.g. whether the

calibration gas flow should be automated. The system configuration can be classified

into three basic patterns as follows:

1.1.1

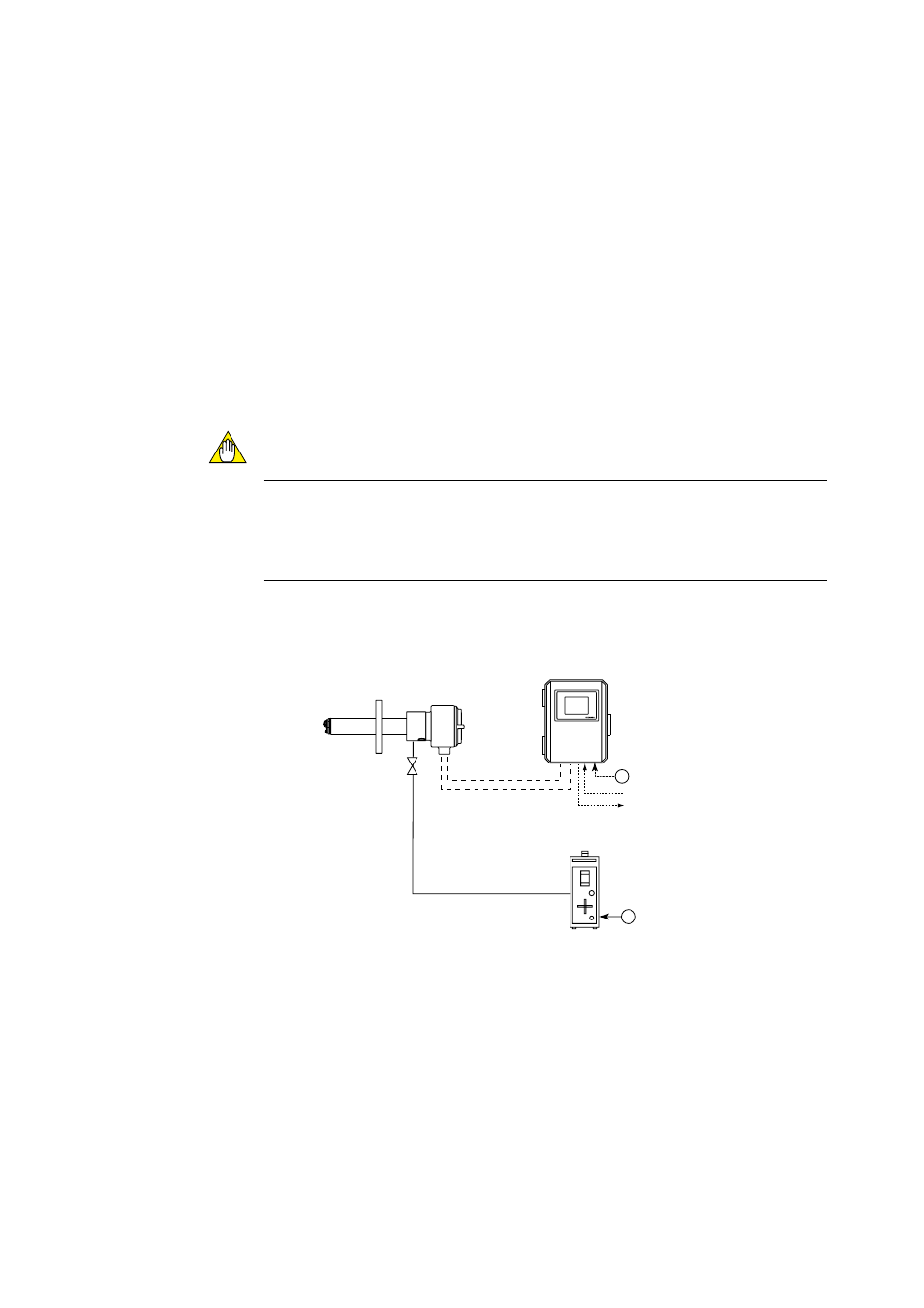

System 1

This is the simplest system consisting of a detector and a converter. This system can be

implemented for monitoring humidity in a production process such as food production.

No piping is required for the reference gas (air) which is fed in at the installation site.

The handy ZO21S standard gas unit is used for calibration.

Zero gas from this unit and span gas (air) is sent to the detector through a tube which is

connected during calibration.

CAUTION

• A needle (stop) valve should be connected to the calibration gas inlet of the detector.

The valve should be fully closed unless calibration is in progress.

• As this system uses ambient air for the reference gas, measuring accuracy will be

affected by the installation location.

EXA ZR402G

Separate type Zirconia

High Temperature Humidity Analyzer,

Model ZR22G Detector

Model ZR402G Converter

Stop valve

Calibration gas

Model ZO21S Standard gas unit

ϳ

ϳ

100 to 240 V AC

F1.1E.EPS

Contact input

Analog outout, contact output

Digital output (HART)

Signal

(6-core shield cable)

Heater (2-core)

Figure 1.1