Routine maintenance – Yokogawa In-Situ Gas Analyzer TDLS200 User Manual

Page 98

7-2

IM 11Y01B01-01E-A 6th Edition :Feb 13, 2013-00

<7. ROUTINE MAINTENANCE>

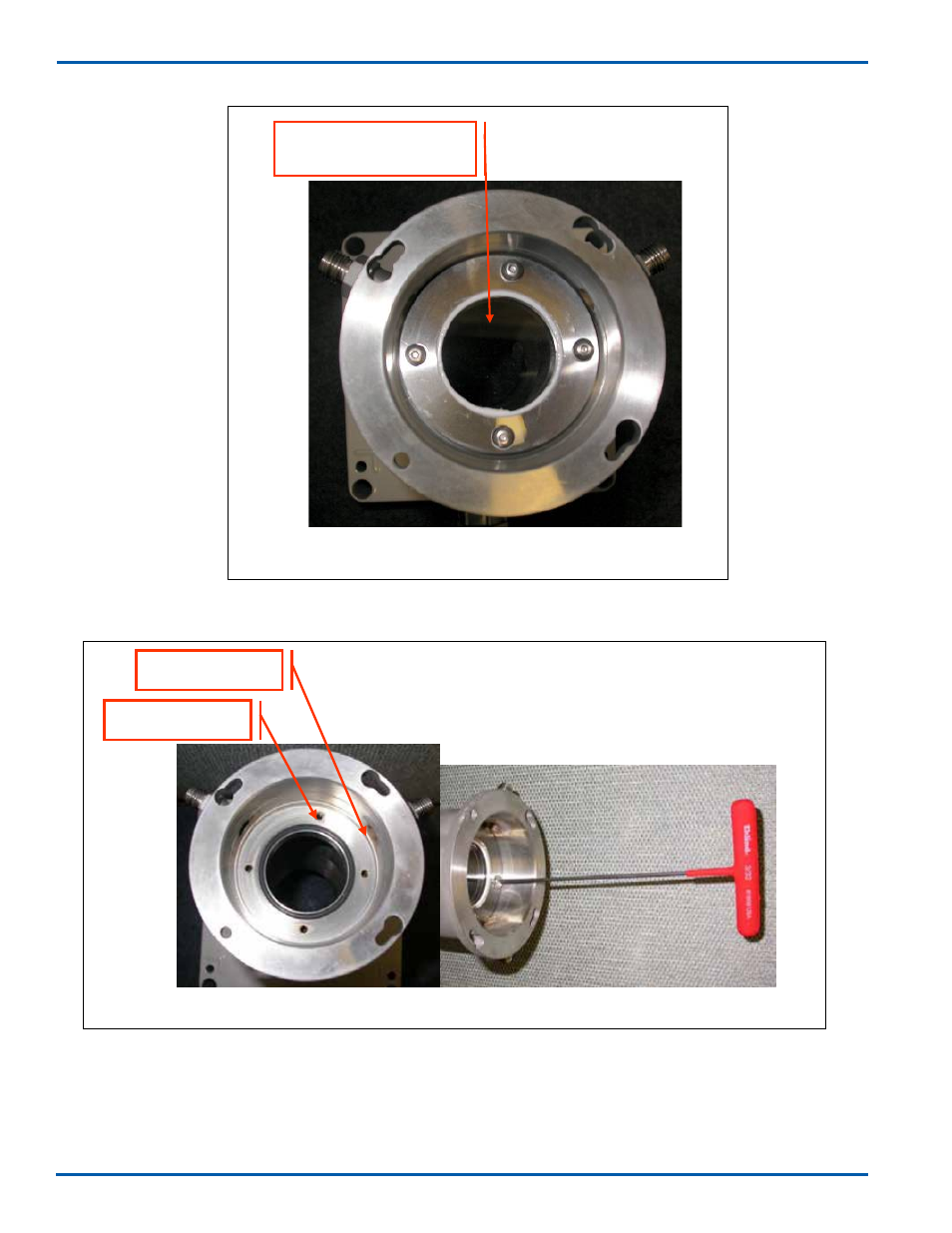

Figure 57 - Window Cleaning

TDLS200 TDL Analyzer Instruction Manual V2.1

Page 88 of 131

- 88 -

Window surface to

be cleaned

If the windows are contaminated they may be cleaned using the following procedure:

•

Remove analyzer from process (isolate, etc. if necessary)

•

Use a clean, dry instrument air or nitrogen pressure supply to first blow off any particulate

matter.

•

Using warm water and mild soap detergent, gently clean the window surface with a soft,

non-abrasive cloth.

•

If the deposits do not come off then use a small amount of IPA (Isopropyl Alcohol) and a

soft, non-abrasive cloth.

•

Use the same clean, dry instrument air or nitrogen pressure supply to blow dry the surface.

•

Carefully check the entire surface of the window from different angles to ensure it is

thoroughly cleaned and ready for service.

•

If the window does not appear to clean up well, then replace the window assembly with a

new one.

•

If the window appears to have an etched surface then it has probably been contaminated

with HF or other similar corrosive gas.

Figure 32 - Window Cleaning

Figure 56 - Window Replacement

TDLS200 TDL Analyzer Instruction Manual V2.1

Page 89 of 131

- 89 -

Figure 33 - Window Replacement

5.1.2 Replacing Windows:

If it has been determined that a window required replacement, then the following should be

performed:

•

Shut down the analyzer and remove power, thus ensuring the laser if OFF.

•

Remove Launch or Detect (as appropriate) from the process interface by removing the one

fixed hole fastener (5/32” Allen Wrench), loosening the remaining three fasteners and then

twisting and pull off the unit.

•

Remove the four retaining screws (3/32” Allen Wrench, T-Handle) and lock washers from

the window holder recessed inside the quick connect body.

•

Remove the window that requires replacement.

•

Ensure the new replacement window is of the same specification as the window being

removed. Standard Windows are 0.25” Thick wedged, BK-7 borosilicate crown glass

mounted in stainless steel retaining ring.

•

The window holder assemblies can only be installed in one way by virtue of the mounting

hole placement.

•

Ensure a new O-Ring (of same specification) is installed at the same time. Viton is the

standard material however, certain applications may require other materials – check original

specifications.

•

With the new O-Ring in position, carefully locate the new window holder in place with the

smooth glass surface against the O-Ring.

•

Carefully tighten all four screws (ensuring the lock washers are in place) using a T-handle

wrench. Keep tightening all the fasteners in turn by ¼ turns thus ensuring an even torque

loading.

•

Hand tighten the screws until they are very firmly tightened (a T handle wrench as shown

below will torque its own shaft by about ¼ turn when the screws are fastened securely).

Offset screw position

for window

O-ring correctly

seated in position

O- ring correctly

seated in position