Basic operation – Yokogawa In-Situ Gas Analyzer TDLS200 User Manual

Page 77

6-20

6-21

IM 11Y01B01-01E-A 6th Edition :Feb 13, 2013-00

<6. BASIC OPERATION>

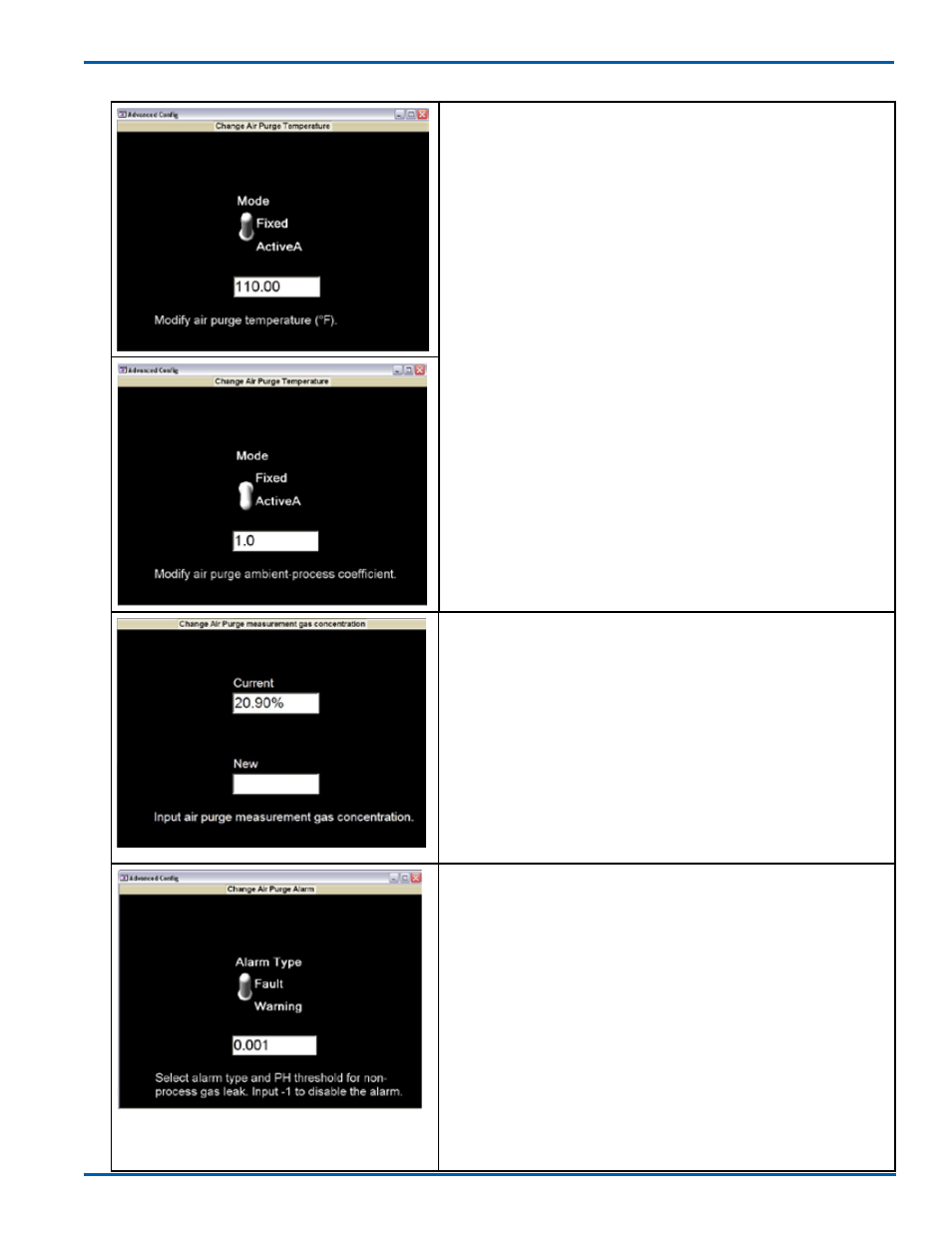

NON-PROCESS TEMPERATURE

This is the temperature of the non-process gas with two modes

of input:

FIXED – manual input of fixed temperature value

ACTIVE AMBIENT - ambient gas temperature derived from

integral sensor on detector circuit with offset adjustment

(typically -5 deg C) and an adjustable coefficient value (1.0

shown left).

To derive the optimum coefficient value, please contact

Yokogawa with installation and application details. This will

ensure the optimal coefficient value taking into account the

temperature gradient from ambient to process gas temperature

for the non-process purge gases.

NON-PROCESS ALARM SELECTION

This allows the selection or disabling of alarm when then non-

process gas peak height falls below the entered threshold

value.

In this example, the analyzer is configured to FAULT Alarm

when the peak height is lower than 0.001 au (see absorption

spectrum). This value can be determined with assistance from

the Yokogawa factory to suit the specific application.

This alarm function can be used to help detect the leakage or

loss of line locking gas, for example %CO on combustion CO/

CH4 applications

To disable this alarm, simply enter -1 as the threshold value

with the toggle in either Fault or Warning position.

NON-PROCESS ALARM SELECTION

This allows the selection or disabling of alarm when then non-

process gas peak height falls below the entered threshold

value.

In this example, the analyzer is configured to FAULT Alarm

when the peak height is lower than 0.001 au (see absorption

spectrum). This value can be determined with assistance from

the Yokogawa factory to suit the specific application.

This alarm function can be used to help detect the leakage or

loss of line locking gas, for example %CO on combustion CO/

CH4 applications

To disable this alarm, simply enter -1 as the threshold value

with the toggle in either Fault or Warning position.