Yokogawa In-Situ Gas Analyzer TDLS200 User Manual

Page 101

8-4

8-1

IM 11Y01B01-01E-A 6th Edition :Feb 13, 2013-00

<8. VALIDATION AND CALIBRATION>

8 Validation and Calibration

There are several methods that can be used to validate and/or calibrate the TDLS200 analyzer. Generally,

we recommend routine validation of the analyzer either on-line (if appropriately set-up) or off-line. when the

process gas can be isolated from the optical path (such as extractive enhanced flow cell).

Actual calibration should only be performed if certain performance criteria have not been met during the

validations and should only be performed by appropriately qualified personnel.

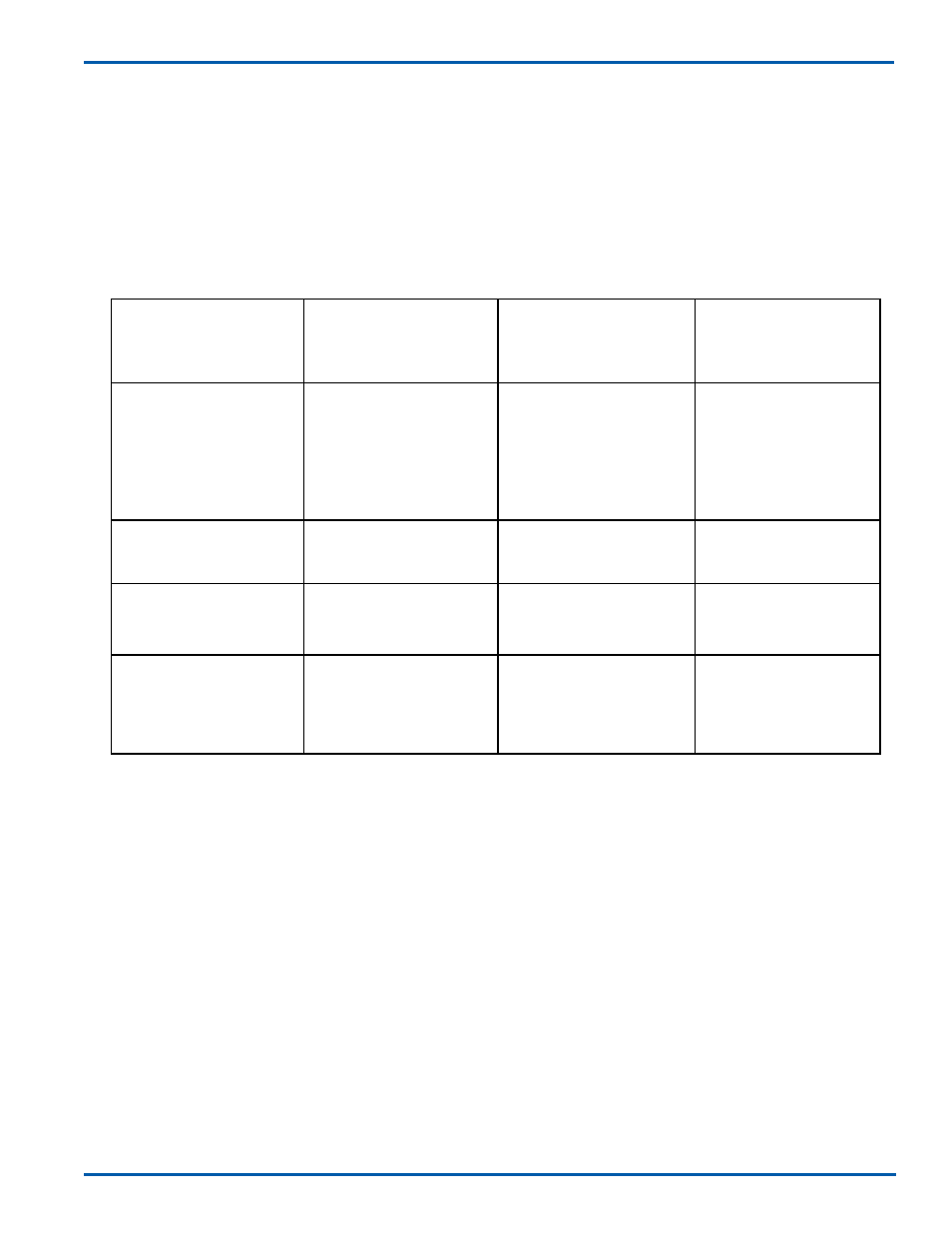

The options for Validation and Calibration are:

Validate On-Line

Manual

Analyzer remains attached to

process and also considered as

a gas response check method

Use integral on-line

check gas flow cell

Manual introduction of check

gas and follow manual proce-

dure via user interface (at RIU,

local LCD or PC with

VNC-Viewer)

Validate On-Line

Automatic

Initiated by:

- Remote Contact

- Local User Interface

- Pre-Set Timer

- URD Laptop VAC

- RIU User Interface

Analyzer remains attached to

process and also considered as

a gas response check method

Use integral on-line

check gas flow cell

Automatic introduction of

check gas (requires

appropriate hardware, valves,

etc.) and implements

automatic procedure from

selected initiation method

Validate Off-Line

(or Cal Check)

Manual (Zero - Span)

Analyzer removed

from the process

alignment flanges

Use off-line calibration

cell

Manual introduction of zero or

span gas and follow manual

procedure via user interface

Calibrate Off-Line

Manual (Zero – Span)

Analyzer removed

from the process

alignment flanges

Use off-line calibration

cell

Manual introduction of zero or

span gas and follow manual

calibration procedure via user

interface

Analyzers with

extractive flow cells

and by-pass piping

Analyzer can remain

in its off-line position

Use flow cell or bypass

piping and

introduce cal gases

Manual or automatic

introduction of Zero and Span

gases for validation or

calibration (when equipped

with appropriate hardware,

valves, etc.)

7-4