Validation and calibration – Yokogawa In-Situ Gas Analyzer TDLS200 User Manual

Page 124

8-24

IM 11Y01B01-01E-A 6th Edition :Feb 13, 2013-00

<8. VALIDATION AND CALIBRATION>

Settings for Validation:

There are several critical parameters that must be preconfigured in the TDLS200 software when using the

automatic validation sequence. These parameters MUST be correctly set otherwise the analyzer will report

false/incorrect validation results.

The settings are configured as below:

• Check Gas Concentration specifies the concentration (ppm) of the gas within the online check

gas flow.

• Check Gas Pathlength specifies the length (in) of the check gas flow cell.

• Check Gas Temperature can be selected for either Fixed or Active.

o If Active Temperature, then follow on screen instructions.

o If Fixed Temperature, then enter in the temperature of the gas within the online check gas flow cell.

Typically this cell is the same temperature as ambient. Remember that this value will be used

whenever the auto validate is used so try to select a value that is representative of when the auto

validate might take place (day/night, etc.) Press ENT to proceed.

TDLS200 TDL Analyzer Instruction Manual V2.1

Page 99 of 131

- 99 -

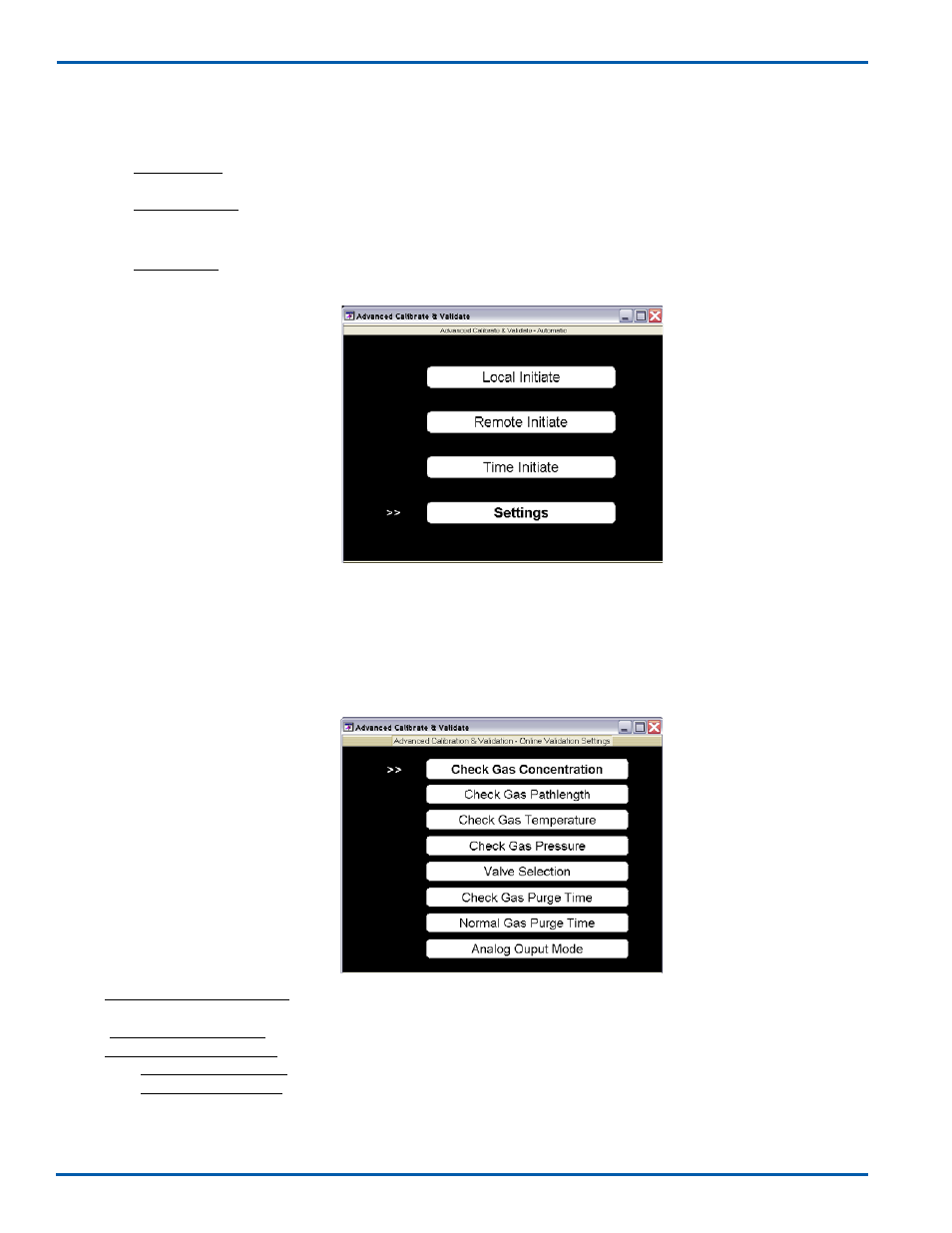

Settings for Validation:

There are several critical parameters that must be preconfigured in the TDLS200 software when

using the automatic validation sequence. These parameters MUST be correctly set otherwise the

analyzer will report false/incorrect validation results.

The settings are configured as below:

•

Check Gas Concentration specifies the concentration (ppm or vol%) of the gas within the

online check gas flow.

•

Check Gas Pathlength specifies the length (in) of the check gas flow cell.

•

Check Gas Temperature can be selected for either Fixed or Active.

o If Active Temperature, then follow on screen instructions.

o If Fixed Temperature, then enter in the temperature of the gas within the online

check gas flow cell. Typically this cell is the same temperature as ambient.

Remember that this value will be used whenever the auto validate is used so try to

select a value that is representative of when the auto validate might take place

(day/night, etc.) Press ENT to proceed.

•

Check Gas Pressure specifies the pressure at which the gas within the online line check

gas flow cell. Typically this cell is vented to atmosphere so an atmospheric pressure value

(14.7 psiA or 1.01barA) will work.

•

Valve Selection specifies which analyzer’s solenoid valve driver is used for the check gas.

•

Check Gas Purge Time specifies how long the check gas will purge the check gas flow cell.

•

Normal gas Purge Time specifies how long the normal gas (usually N2) will purge the check

gas flow cell.

•

Analog Output Mode specifies Block, Track, or Hold of all 4 to 20 mA output during online

check.

TDLS200 TDL Analyzer Instruction Manual V2.1

Page 98 of 131

- 98 -

Initiating Validation:

There are several ways in which the Automatic Validation sequence can be initiated:

•

Remote Contact – The analyzer has the ability to monitor a pair of voltage free contacts.

These contacts would typically be located at the DCS or a simple switch located near the

analyzer. The analyzer continuously monitors the remote contacts (or switch) for a return

voltage (24VDC generated by the analyzer). When the contacts close, the return voltage is

sensed and the Auto Validation sequence is initiated.

•

Local User Interface – The TDLS200 software allows for the user (either through a laptop

PC running VAC software or via installed 6.5” display & Keypad) to initiate the Auto

Validation sequence. The operator would be at the analyzer in this case.

•

Preset Timed – The TDLS200 software allows for the analyzer to automatically initiate the

Auto Validation sequence based on a user configurable timed basis.

•

URD & Laptop PC with VAC software – The TDLS200 software allows for the user through

a laptop PC running VAC software to initiate the Auto Validation sequence. The operator

would be at the URD with the laptop PC plugged in to the Ethernet port on the URD Feed

Through board.

•

RIU with VAC software – The TDLS200 software allows for the user through an RIU

running VAC software to initiate the Auto Validation sequence. The operator would be at

the RIU in this case.

Selecting Automatic Validation Initiation

From Online Validations – Automatic menu, the following options may be selected.

•

Local Initiate will start the automatic online validation sequence when selected. It will use

the existing ‘Settings’ (see below for details on ‘Settings’).

•

Remote Initiate will enable/disable monitoring of the selected “Remote Initiate” contacts on

TB-2 within the Launch Unit. When enabled, the analyzer will detect the chosen contact

closure and automatically start the online validation sequence.

•

Time Initiate will allow input of a specified time to automatically start online validation

sequence once every day, every week, every 2 weeks, or every 4 weeks.

Selecting Automatic Validation Initiation

From Online Validations – Automatic menu, the following options may be selected.

• Local Initiate will start the automatic online validation sequence when selected. It will use the existing

‘Settings’ (see below for details on ‘Settings’).

• Remote Initiate will enable/disable monitoring of the selected “Remote Initiate” contacts on TB-2

within the Launch Unit. When enabled, the analyzer will detect the chosen contact closure and

automatically start the online validation sequence.

• Time Initiate will allow input of a specified time to automatically start online

validation

sequence

once every day, every week, every 2 weeks, or every 4 weeks.