General specifications – Yokogawa In-Situ Gas Analyzer TDLS200 User Manual

Page 17

Performance Specification

Repeatability:

Application Dependent

Linearity:

+/- 1% of FS

Response time:

2-20 seconds, plus transport time for

extractive systems when applicable

Drift:

Application Dependant

Installation Specifications

Hazardous Area:

Zone 1: Contact Yokogawa

Zone 2: ATEX group II Cat. 3G with purge

system EEx pz II T5 (-20< Ta <50C)

By Design:

Non-Hazardous Area; Purge required for

ATEX zone 1&2 and NEC Class 1

Division 1&2

Maximum Distance between Launch and Detect:

30 m (±90ft)

Maximum interconnecting cable 50m

Wetted Parts:

Analyzer & standard Alignment Flange - 316

SS, BK-7 Glass, Teflon encapsulated Viton

and Silicone RTV sealant.

Optional:

Isolation Flanges and Flow Cells - 316 SS,

Sapphire, Kalrez -

Also available in Monel A400, Hastelloy

C-276, Carpenter 20, Titanium Grade 2 and

others on request.

Utilities:

Instrument Air may be used as a purge gas in principle for all of the

below applications, but this will depend on the application type and the

required precision of the measurement.

Oxygen Analyzer

N

2

CO Analyzer

N

2

or Instrument Air

CO

2

Analyzer

N

2

or other non-CO

2

containing inert gas

H

2

O ppm Analyzer

N

2

with <20ppm levels H

2

O for feed to

optional Dryer Package

H

2

O % Analyzer

N

2

Flow Rate:

• 5-30 L/min for window purge

• 2 L/min for validation, calibration and optical

purge

SIL Assessment:

The TDLS200 has a FMEDA assessment by exida and is

classified as a Type B1 device in compliance with the following

standards; IEC 61508 or EN 954-1. Functional Safety of Electrical/

electronic/programmable electronic related systems; SIL 1

capability for single device.

* The TDLS200 is not SIL certified as standard; to be certified the unit

must be specified and designed from the beginning to meet all SIL

specifications.

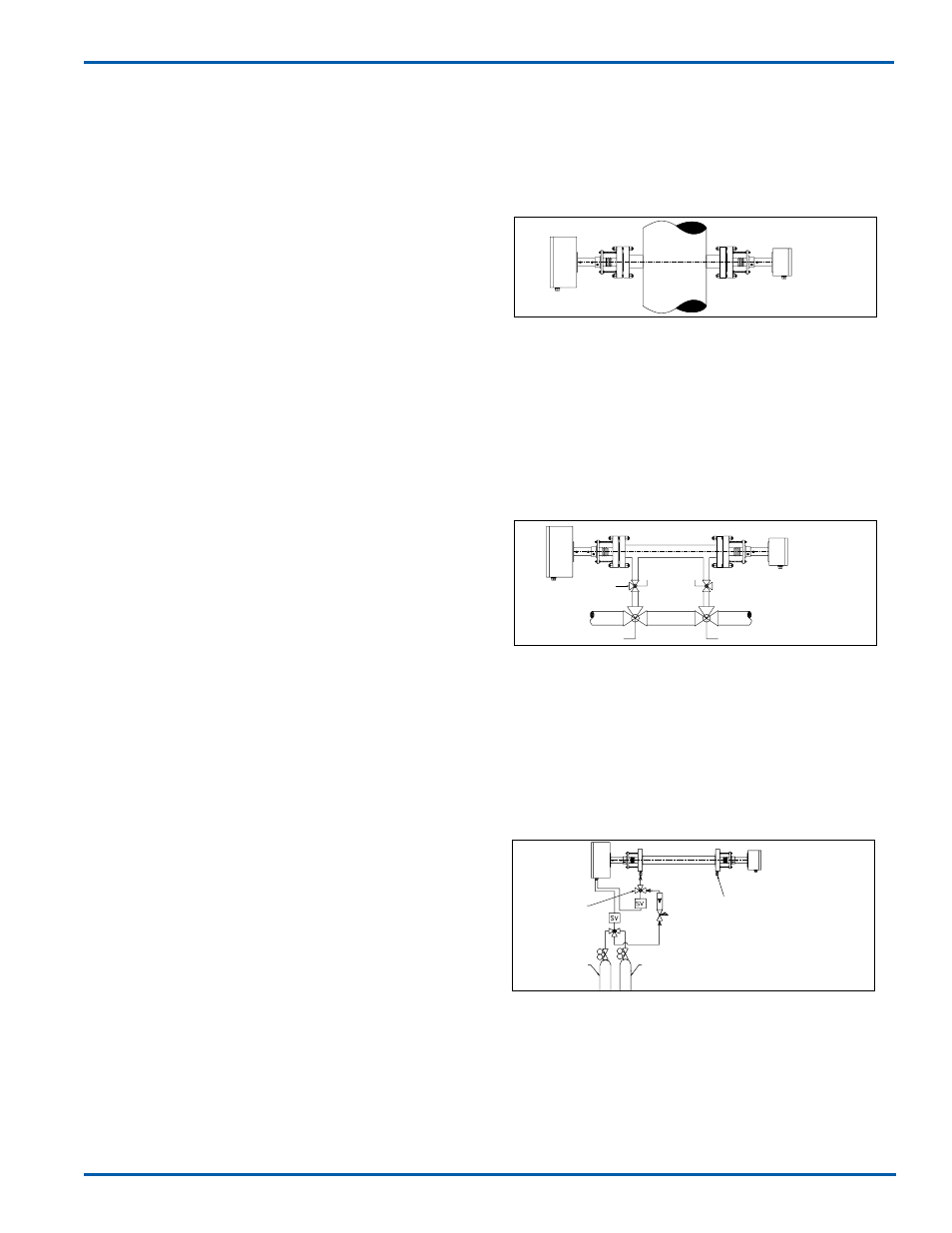

Basic System Configuration

The TruePeak can be installed in a number of ways depending on

process requirements. The most typical installation types are shown

below, however other installation methods are possible, please contact

Yokogawa with your application details.

Cross Stack/Pipe Configuration

• Measures directly across process pipe or vessel

• Typically has nitrogen or other purge gas protecting

process windows

• Span Validation via serial flow cell (see Operation Specifications).

• Full calibration requires removal from process

• May require pressure and temperature inputs

(Application Dependant)

• Multiple methods to increase Optical Path Length (OPL) if needed

• 5 meter interconnection cable standard

Close Coupled Extractive / Bypass Configuration*

• Measures across a section of pipe where process flow

is directed

• The measurement section can be isolated from process flow for full

calibration/validation, zero and span

• Process pressure and temperature can be controlled

or the analyzer may require pressure and temperature inputs

(Application Dependant)

• Length of measurement section dependant on accuracy requirements

and process conditions

Extractive Configuration*

• Sample is fully extracted from process

(and may be conditioned before measurement).

• Flow cells are available with ability to purge in front of windows

(balanced flow cell) if required.

• Process pressure and temperature can be controlled

or the analyzer may require pressure and temperature inputs

(Application Dependant)

• Length of flow cell dependant on accuracy requirements

and process conditions

* Contact Yokogawa for further details

Zero check gas,

at grade

Span check gas.

at grade

Flow-Cell-Outlet

process

sample

inlet

Cal

inlet

PROCESS

3-1

3-2

IM 11Y01B01-01E-A 6th Edition :Feb 13, 2013-00

<3. GENERAL SPECIFICATIONS>