Validation and calibration – Yokogawa In-Situ Gas Analyzer TDLS200 User Manual

Page 104

8-4

IM 11Y01B01-01E-A 6th Edition :Feb 13, 2013-00

<8. VALIDATION AND CALIBRATION>

Procedure for Alignment Optimization on Calibration Cell

1. The launch unit should be adjusted so that the transmission is maximized for off-line calibration

2. Ensure launch unit alignment nuts are securely fastened so that the launch unit cannot move it’s alignment

position

3. To optimize the detect unit alignment, make small adjustments in alignment nuts of detect alignment flange

while increasing the transmission value

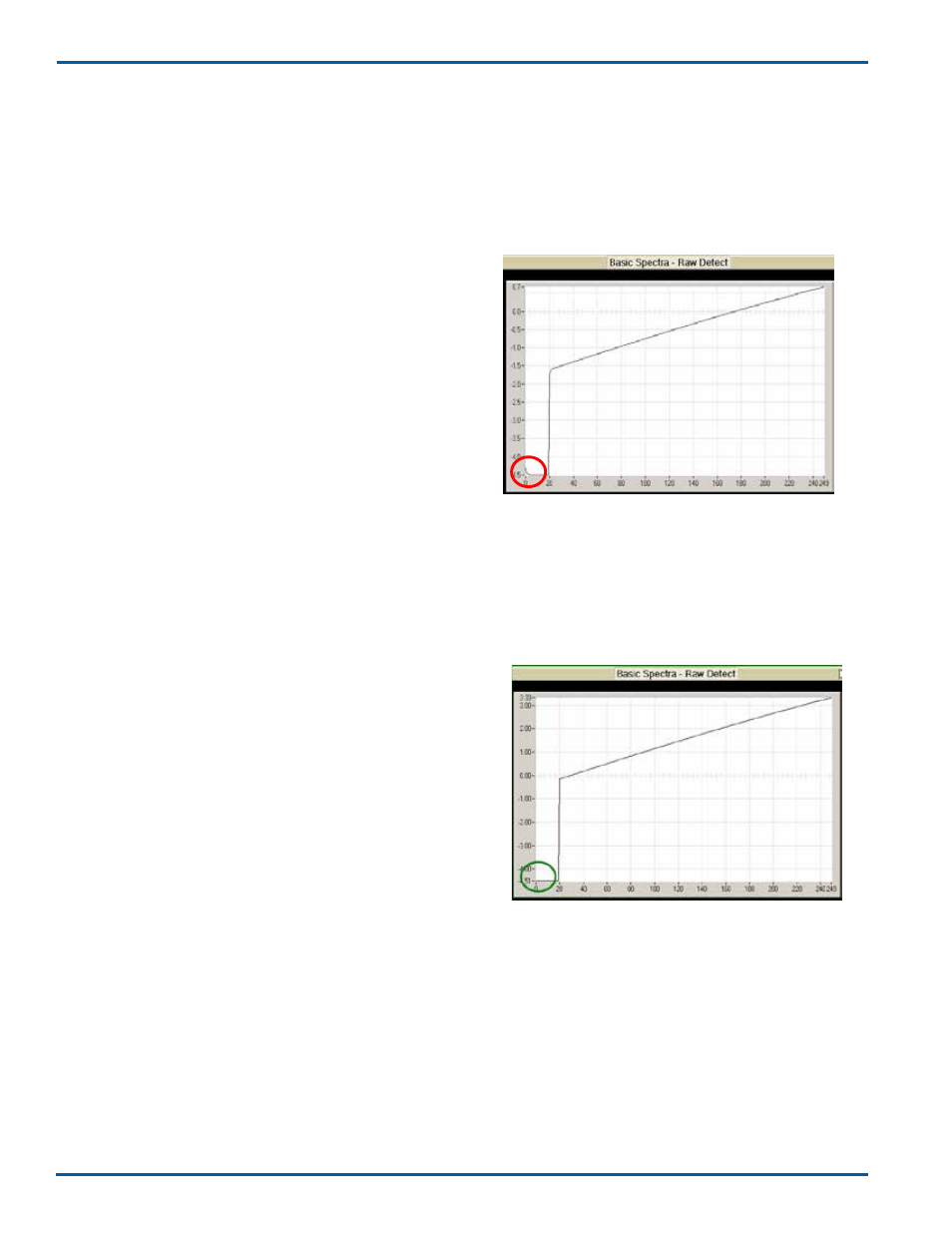

4. When the transmission value is maximized, observe the Raw Detector Signal to ensure the initial 20 data

points are at the baseline condition (i.e. flat data points

from 0-20).

5. If the value of these 0-20 data points decline (i.e. not a

flat line) then this is an indication of some small

misalignment of the system

6. (see POOR alignment example right)

Carefully make small adjustments in the alignment of launch unit to minimize the slope at the start of the raw

detector ramp. Then, Carefully make small adjustments in the alignment of detect unit to minimize the slope at

the start of the raw detector ramp for good alignment

(see GOOD alignment example right)

7. Ensure transmission level is still good

8. Apply manual force to the launch unit (vertical and

horizontal) to ensure the transmission remains stable

and that the system is mechanically tight. If there is

any movement or change in transmission then ensure

all alignment nuts are secured and check again for

mechanical stability.

9. Apply manual force to the detect unit (vertical and

horizontal) to ensure the transmission remains stable

and that the system is mechanically tight. If there is

any movement or change in transmission then ensure

all alignment nuts are secured and check again for

mechanical stability.