Introduction – Yokogawa digitalYEWFLO (DY) User Manual

Page 6

INTRODUCTION

IM 1F2B4-01-YIA

Page 2

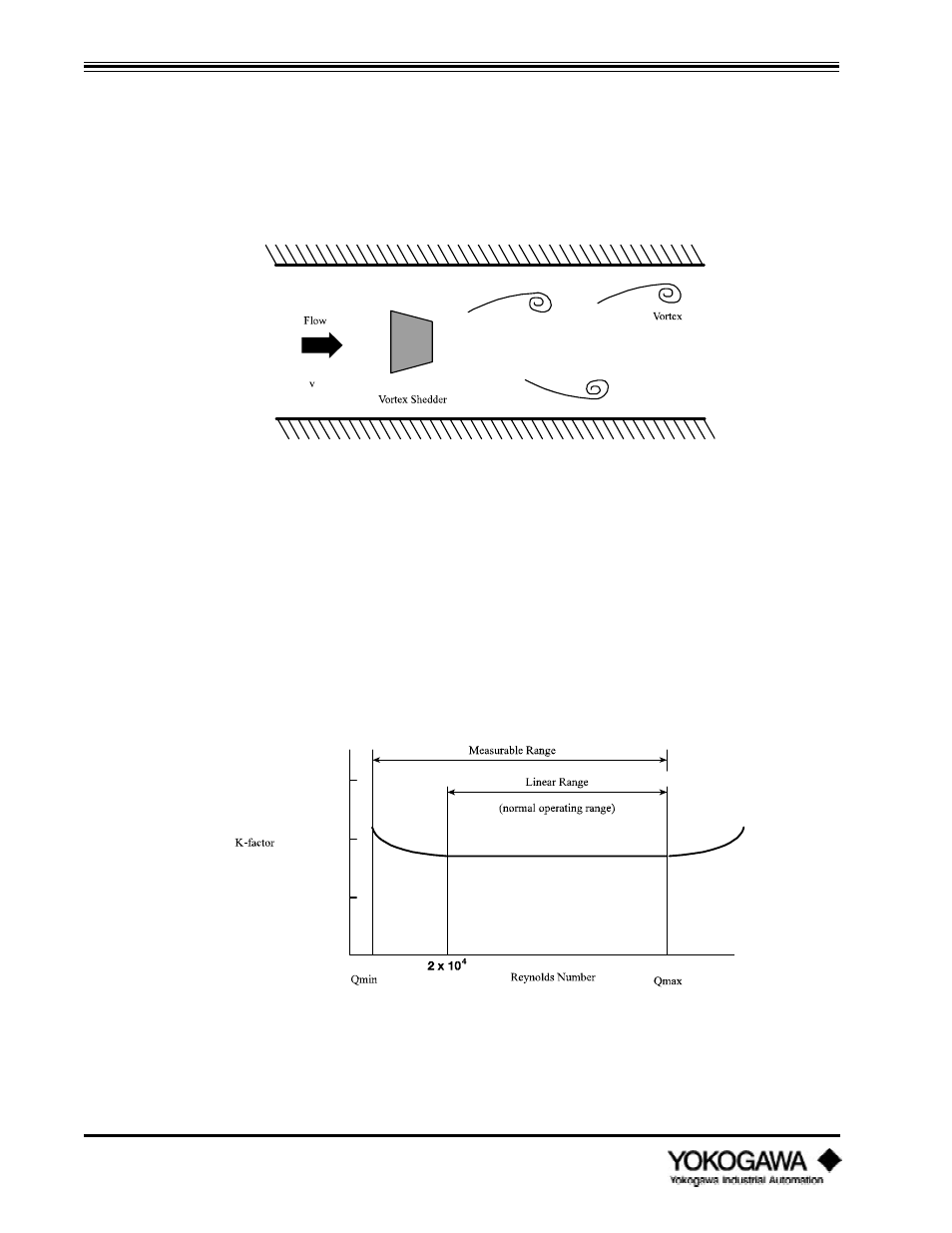

The flapping flag is a familiar example of vortex shedding that everyone should be comfortable with.

Here’s how it’s used in a vortex flowmeter. A non-streamlined part (bluff body) is inserted in the flow

stream, this obstruction in the pipe causes vortices to be alternately created (shed). We call this part

the ‘shedder bar’. The shedder bar in a YEWFLO performs two functions, it creates the vortices, and

with the addition of our piezoelectric crystals senses them too. The crystals generate an alternating

voltage waveform whose frequency is proportional to fluid velocity. The rest of the magic is taken care

of in the electronics.

Figure 1.2.1: Karman Vortices

1.2.2

K-factor

The most important fact about vortex shedding is that once the physical geometry, (pipe I.D., shedder

bar width, etc.), are fixed, the frequency vs. flowrate (K-factor (pulse/gallon)) is unaffected by

changes in viscosity, density or pressure over the operating range of the specific application. To

determine the operating range use the YEWFLO Sizing program. On the other hand, an orifice plate is

directly affected by changes in any of these parameters. There is a very small temperature effect due to

expansion or contraction of the shedder bar width, which is easily compensated. Therefore, the K-

factor created in our flow stand (all YEWFLOs are wet flow calibrated) on water, is accurate for gas

too! Not so with an orifice plate. The benefit here is simplified calculations, and fewer things that

can effect accuracy .

Figure 1.2.2: Relationship between K-factor and Reynolds Numbers