Installation – Yokogawa digitalYEWFLO (DY) User Manual

Page 34

IM 1F2B4-01-YIA

Page 38

INSTALLATION

3.1.4

Flushing the pipe

On a new installation we recommend flushing the pipeline and removing any and all scales on the

inside of the pipe before installing the vortex meter. The bypass piping should be installed around the

vortex meter to facilitate pipe cleaning. When there is no bypass piping, the vortex meter should be

temporarily removed and a spool piece installed in its place.

3.1.5

Gaskets

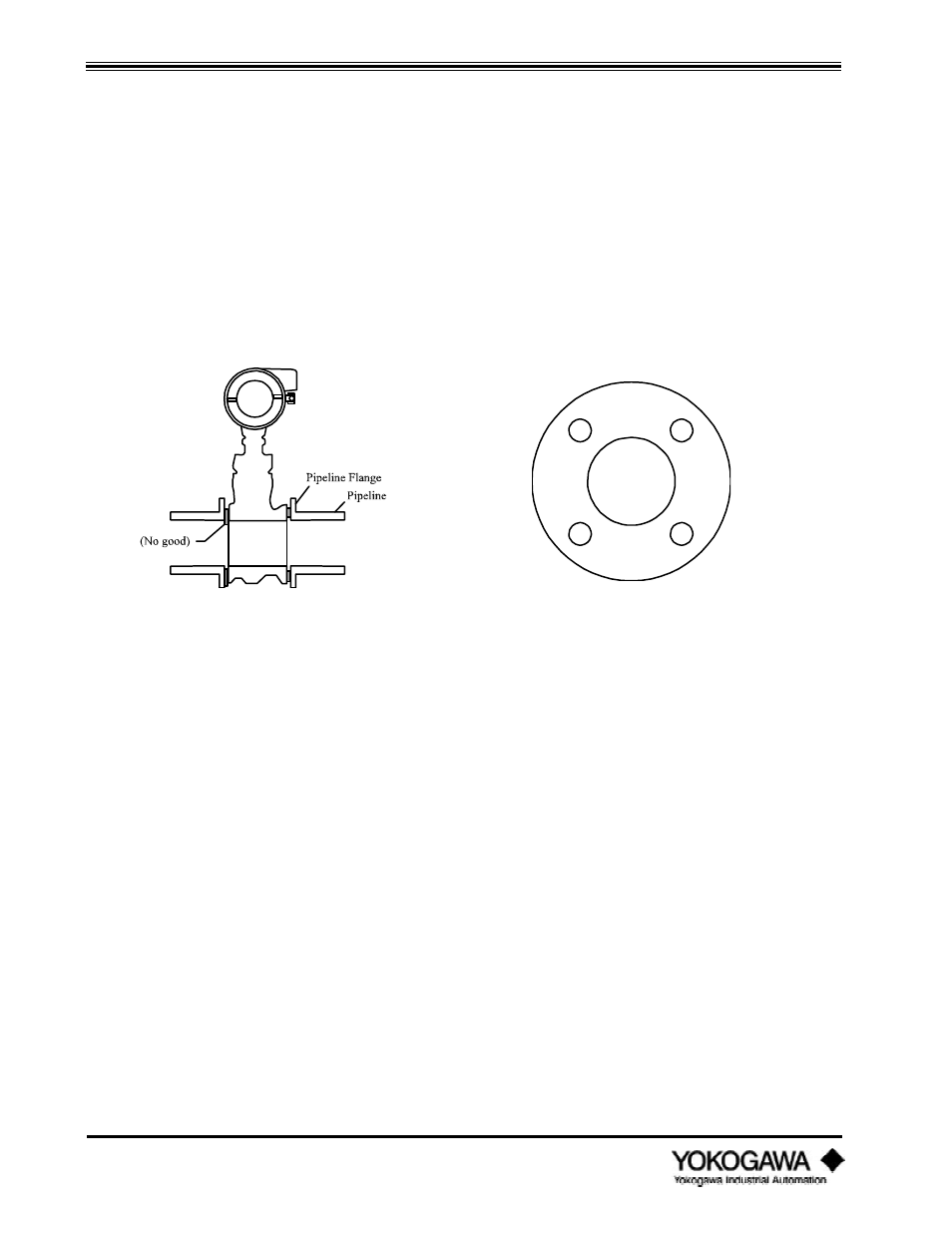

The ID of the gaskets must be equal to or larger than the ID of the meter and mating pipe. The

gaskets should be the self-centering type. It is important that the gaskets not protrude into the flow

stream, otherwise accuracy will be adversely affected.

Figure 3.1.4: Gasket cross section

Figure 3.1.5: Typical gasket with bolt holes

3.2

I

NSTALLING

THE

V

ORTEX

M

ETER

Before installing the vortex meter, verify the arrow on the meter body is facing the same direction as

the direction of the flow.

3.2.1

Installing the wafer style vortex meter

When installing the wafer type vortex meter it is important to align the instrument bore with the

inner diameter of the adjacent piping. For meters in sizes ½" through 3", four alignment collars are

supplied. These collars establish a predetermined spacing between the mounting bolts and the

outside diameter of the vortex meter body. The bolts must be of the proper diameter to establish

alignment. Carbon steel stud bolts and nuts are supplied as standard. Stainless steel (304) stud bolts

and nuts are optional. Gaskets are supplied by the user. Check all mating flanges ensuring all weld

slag is ground off and the inside surface is clean and smooth.