Yokogawa ADMAG AXF User Manual

Page 75

IM 01E20D01-01E

6-13

6. OUTLINE

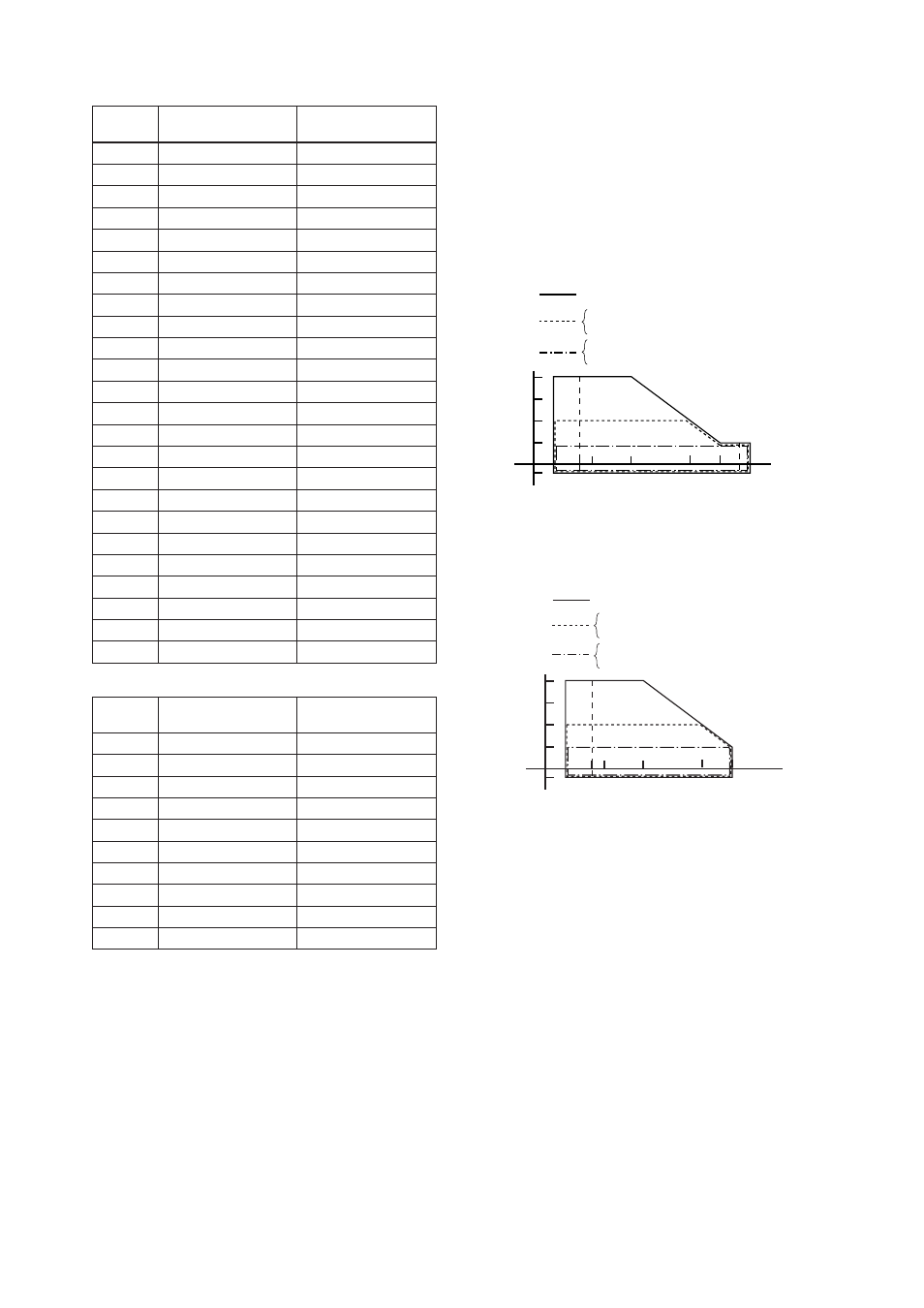

English Units (Size: in., Flow rate: GPM)

0 to Min. Span Flow Rate

(0.33ft/s)

0 to Max. Span Flow Rate

(33ft/s)

0 to 0.0078 GPM

0.1

0 to 0.7780 GPM

0 to 0.0312

0.2

0 to 3.112

0 to 0.1245

0.4

0 to 12.44

0 to 0.1946

0.5

0 to 19.45

0 to 0.7781

1.0

0 to 77.80

0 to 1.216

1.25

0 to 121.5

0 to 1.751

1.5

0 to 175.0

0 to 3.113

2.0

0 to 311.2

0 to 4.863

2.5

0 to 486.2

0 to 7.003

3.0

0 to 700.2

0 to 12.45

4.0

0 to 1,244

0 to 19.46

5.0

0 to 1,945

0 to 28.01

6.0

0 to 2,800

0 to 49.80

8.0

0 to 4,979

0 to 77.81

10

0 to 7,780

0 to 112.1

12

0 to 11,203

0 to 152.5

14

0 to 15,249

0 to 199.2

16

0 to 19,918

Size

(in.)

0 to 311.3

20

0 to 31,122

0 to 448.2

24

0 to 44,815

0 to 610.0

28

0 to 60,999

0 to 796.8

32

0 to 79,672

0 to 1,009

36

0 to 100,835

0 to 1,245

40

0 to 124,488

T24.EPS

0 to Min. Span Flow Rate

(1.0ft/s)

0 to Max. Span Flow Rate

(33ft/s)

0 to 4,519 GPM

44

0 to 150,630 GPM

0 to 5,378

48

0 to 179,262

0 to 6,807

54

0 to 226,879

0 to 8,403

60

0 to 280,098

0 to 9,561

64

0 to 318,689

0 to 12,101

72

0 to 403,341

0 to 14,939

80

0 to 497,952

0 to 18,076

88

0 to 602,522

0 to 21,512

96

0 to 717,051

0 to 25,247

104

0 to 841,540

Size

(in.)

T24-1.EPS

Fluid Temperature and Pressure:

Note *1 The following figures show maximum allowable

fluid pressure for the flowtube. Further fluid

pressure should also be limitted according to

flange rating.

*2 For fluid temperature of the explosion proof type,

refer to descriptions of “HAZARDOUS AREA

CLASSIFICATION”.

PFA Lining (*1)

General-Purpose Use, Submersible Type, Explosion

proof Type, Remote Flowtube (electrode structure

code 1: Non-replaceable electrode)

Pressure

MPa (psi)

4 (580)

2 (290)

1 (145)

– 0.1 (–14.5)

– 40

(–40)

40

(104)

100

(212)

160

(320)

Temperature

°C (°F)

130

(266)

2.5 to 50 mm (0.1 to 2.0 in.) (flange type, wafer type)

65 to 200 mm (2.5 to 8.0 in.) (flange type, wafer type)

250, 300 mm (10, 12 in.) (flange type)

250, 300 mm (10, 12 in.) (wafer type)

350, 400 mm (14, 16 in.) (flange type)

0

(32)

–10

(14)

F18-1.EPS

150

(302)

*1

General-Purpose Use and Explosion proof Type,

Integral Flowmeter (electrode structure code 1: Non-

replaceable electrode)

Pressure

MPa (psi)

4 (580)

2 (290)

1 (145)

– 0.1 (–14.5)

– 40

(– 40)

40

(104)

100

(212)

Temperature

°C (°F)

130

(266)

0

(32)

–10

(14)

2.5 to 50 mm (0.1 to 2.0 in.) (flange type, wafer type)

65 to 200 mm (2.5 to 8.0 in.) (flange type, wafer type)

250, 300 mm (10, 12 in.) (flange type)

250, 300 mm (10, 12 in.) (wafer type)

350, 400 mm (14, 16 in.) (flange type)

F18-2.EPS

*1

*1:

For wafer types of 32 mm to 300 mm(1.25 to 12 in.), and

for carbon steel flange types (process connection code:

C

**

) of 50 to 400 mm (2.0 to 16 in.), the minimum tem-

perature is –10

°C (14°F).

*2:

For fluid temperature of the explosion proof type, refer

to descriptions of “HAZARDOUS AREA CLASSIFI-

CATION”.