Yokogawa ADMAG AXF User Manual

Page 15

IM 01E20D01-01E

3-5

3. INSTALLATION

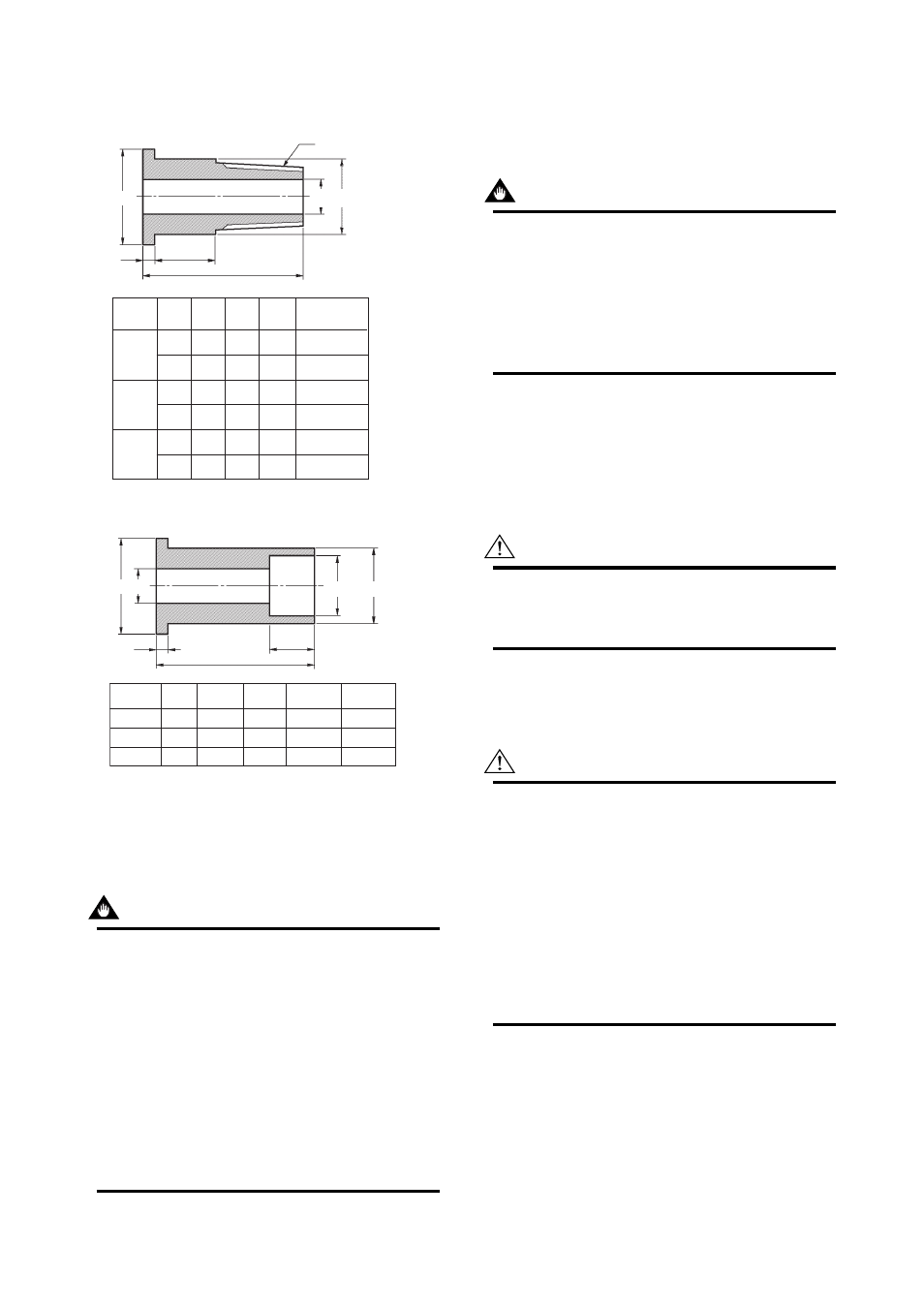

Table 3.3.1

Fitting Dimensions

Size

mm(inch)

Code

A

B

C

D

2.5

(0.1)

10

(0.4)

5

(0.2)

GUR

GUN

GUR

GUN

GUR

GUN

22

(0.87)

22

(0.87)

22

(0.87)

22

(0.87)

25

(0.98)

25

(0.98)

8

(0.31)

8

(0.31)

8

(0.31)

8

(0.31)

10

(0.39)

10

(0.39)

18.5

(0.73)

18.5

(0.73)

18.5

(0.73)

18.5

(0.73)

22.5

(0.89)

22.5

(0.89)

R1/4(PT1/4)

NPT1/4

R1/4(PT1/4)

NPT1/4

R3/8(PT3/8)

NPT3/8

D

A

4

(0.16)

11.5(0.45)

30(1.18)

B C

0

-0.1

Screw joint (process connection codes: GUR and GUN)

T0301.EPS

A B

4

(0.16)

35(1.38)

10(0.39)

+0.3

0

0

-0.1

C

D

Weld joint (process connection code: GUW)

Size

mm(inch) Code

GUW

GUW

GUW

A

B

C

D

T0302.EPS

2.5 (0.1)

10 (0.4)

5 (0.2)

22(0.87)

22(0.87)

25(0.98)

8(0.31)

8(0.31)

10(0.39)

14.3(0.56)

14.3(0.56)

17.8(0.70)

18.5(0.73)

18.5(0.73)

22.5(0.89)

(1) Mounting Direction

Mount the flowmeter so that the flow direction of the

fluid to be measured is in line with the direction of the

arrow mark on the flowmeter.

IMPORTANT

If it is impossible to match the direction of the

arrow mark, the direction of the electrical con-

nection can be changed. Refer to Section 5.1 to

do this properly.

In case the fluid being measured flows against

the arrow direction, refer to the parameter J20:

Flow Direction in the user’s manual of the

AXFA11 Magnetic Flowmeter Remote Converter

(IM 01E20C01-01E) or the AXFA14 Magnetic

Flowmeter Remote Converter/AXF Integral

Flowmeter [Software Edition] (IM 01E20C02-

01E).

(2) Connecting Process Piping

Weld or screw the connection fittings to the process

piping.

IMPORTANT

• Be sure to pass the connection fittings through

the union joint nuts in advance.

• When welding the fittings, pay attention to the

edge preparation, level differences between the

fittings and the piping, and the welding current

to avoid deforming the piping or causing

stagnation portion of the fluid.

(3) Positioning the Flowmeter

Install the flowmeter on a mounting base and position

it so that the center axis of the flowtube is aligned with

that of the process piping. Then screw the union joint

nuts to the connecting ports of the flowmeter.

CAUTION

Ceramics pipes may be damaged if the nuts are

tightened when the center axes are not properly

aligned.

(4) Tightening Nuts

Use a torque wrench to tighten the union joint nuts.

CAUTION

Tighten the union joint nuts according to the

tightening torque values in Table 3.3.2. For

permeable fluid (such as nitric acid, hydrofluoric

acid or sodium hydrate at high temperature),

tighten the nuts according to the torque values in

Table 3.3.3.

As the gasket material is fluorocarbon PTFE, it is

possible that the nuts may loosen as time

passes. Retighten the nuts if this is the case. Be

sure to use the gasket (thickness is 1.5 mm)

which comes with the flowmeter.