Yokogawa ADMAG AXF User Manual

Page 18

IM 01E20D01-01E

3-8

3. INSTALLATION

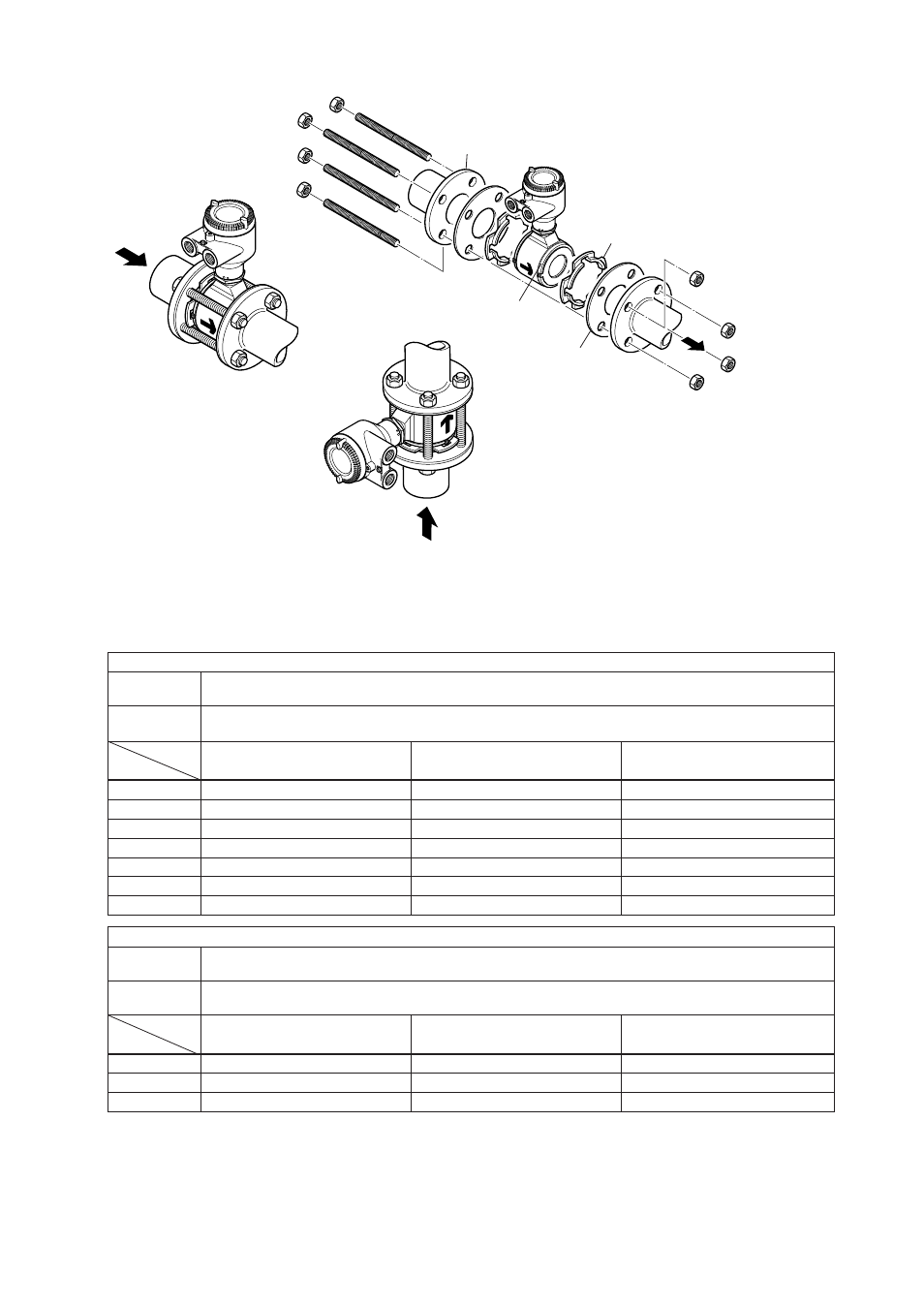

Figure 3.3.3 Mounting Procedure for Wafer Type (size: 25 (1.0), 32 (1.25), and 40 mm (1.5 in.))

Table 3.3.4

Wafer Type Tightening Torque Values for Metal Piping

JIS 10K, ANSI Class 150, and DIN PN10

JIS 20K, ANSI Class 300, and DIN PN16

DIN PN40

15 (0.5)

25 (1.0)

40 (1.5)

Tightening torque values for Ceramics lining type (N-m / {kgf-cm} / [in-lbf])

2.9 to 4.8 / {29.57 to 48.95} / [25.67 to 42.48]

8.2 to 13.6 / {83.62 to 138.7} / [72.57 to 120.4]

14.1 to 23.6 / {143.8 to 240.7} / [124.8 to 208.9]

2.9 to 4.8 / {29.57 to 48.95} / [25.67 to 42.48]

8.2 to 13.7 / {83.62 to 139.7} / [72.57 to 121.3]

14.4 to 24.1 / {146.8 to 245.8} / [127.4 to 213.3]

3.0 to 5.0 / {30.59 to 50.99} / [26.55 to 44.25]

7.9 to 13.1 / {80.56 to 133.6} / [69.92 to 115.9]

15.5 to 25.8 / {158.1 to 263.1} / [137.2 to 228.3]

T0305.EPS

Flange ratings

Size

mm (inch)

Non-asbestos gasket, PTFE-sheathed non-asbestos gasket (optional codes BCF and BSF), or the equivalent in hardness

Fluororesin with ceramic fillers (Valqua #7020) (standard) gasket, or fluororesin with carbon gasket (optional code GF)

JIS 10K, ANSI Class 150, and DIN PN10

JIS 20K, ANSI Class 300, and DIN PN16

DIN PN40

Flange ratings

Size

mm (inch)

2.5 (0.1)

5 (0.2)

10 (0.4)

15 (0.5)

25 (1.0)

32 (1.25)

40 (1.5)

7.2 to 8.4 / {73.42 to 85.66} / [63.72 to 74.35]

7.2 to 8.4 / {73.42 to 85.66} / [63.72 to 74.35]

7.2 to 8.4 / {73.42 to 85.66} / [63.72 to 74.35]

7.2 to 8.4 / {73.42 to 85.66} / [63.72 to 74.35]

23.5 to 27.3 / {239.6 to 278.4} / [208 to 241.6]

26.2 to 30.5 / {267.2 to 311} / [231.9 to 269.9]

36.2 to 42.4 / {369.1 to 432.4} / [320.4 to 375.3]

7.3 to 8.4 / {74.44 to 85.66} / [64.61 to 74.35]

7.3 to 8.4 / {74.44 to 85.66} / [64.61 to 74.35]

7.3 to 8.4 / {74.44 to 85.66} / [64.61 to 74.35]

7.3 to 8.4 / {74.44 to 85.66} / [64.61 to 74.35]

23.7 to 27.3 / {241.7 to 278.4} / [209.8 to 241.6]

26.6 to 30.5 / {271.2 to 311} / [235.4 to 269.9]

36.9 to 42.4 / {376.3 to 432.4} / [326.6 to 375.3]

7.6 to 8.4 / {77.5 to 85.66} / [67.26 to 74.35]

7.6 to 8.4 / {77.5 to 85.66} / [67.26 to 74.35]

7.6 to 8.4 / {77.5 to 85.66} / [67.26 to 74.35]

7.6 to 8.4 / {77.5 to 85.66} / [67.26 to 74.35]

22.3 to 27.3 / {227.4 to 278.4} / [197.4 to 241.6]

28.0 to 30.5 / {285.5 to 311} / [247.8 to 269.9]

39.1 to 42.4 / {398.7 to 432.4} / [346.1 to 375.3]

Gasket types

within flowtube

Gasket types

for user’s flange

Gasket types

within flowtube

Gasket types

for user’s flange

No gasket (standard)

Non-asbestos fiber gasket, PTFE-sheathed non-asbestos gasket (optional codes BCF and BSF), or the equivalent in hardness

Tightening torque values for PFA/Polyurethane Rubber lining type (N-m / {kgf-cm} / [in-lbf])

F0311a.EPS

*: These items can be ordered optionally.

If they are provided by the user, choose nuts and

bolts in compliance with the flange ratings.

*Nut (eight units)

*Through-bolt (four units)

Centering device (two units)

*Gasket (two units)

Piping-side flange

Mini-flange

Horizontal mounting

F0311b.EPS

Vertical mounting

F0311c.EPS