Yokogawa ADMAG AXF User Manual

Page 31

IM 01E20D01-01E

3-21

3. INSTALLATION

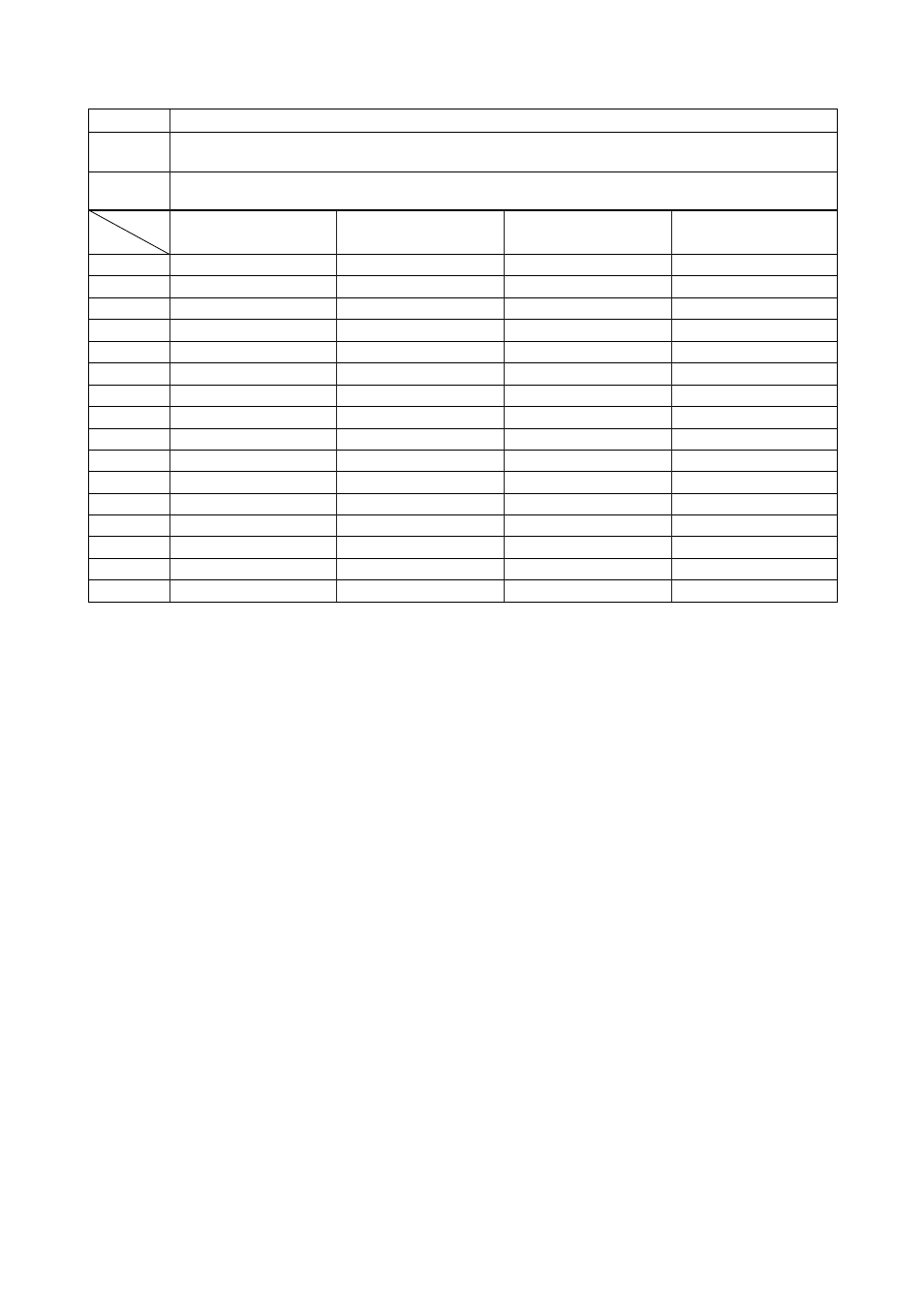

Table 3.3.19

Flange Type Tightening Torque Values for Material Piping

Rubber gasket, or the equivalent in hardness

JIS 10K

ANSI Class150

DIN PIN10

JIS F12

(JIS 75M)

Size 500 to 1000 mm: No gasket

Size 1100 to 2600 mm: Butadiene-styrene-rubber+Natural rubber

Tightening torque values for Polyurethane Rubber lining (N-m / {kgf-cm} / [in-lbf])

43 to 72 / {438.5 to 734.2}/[380.6 to 637.2]

52 to 87 / {530.3 to 887.2}/[460.2 to 770.0]

69 to 116 / {703.6 to 1183}/[610.7 to 1027]

71 to 119 / {724.0 to 1213}/[628.4 to 1053]

93 to 155 / {948.3 to 1581}/[823.1 to 1372]

150 to 249 / {1530 to 2539}/[1328 to 2204]

—

—

—

—

—

—

—

—

—

—

43 to 71 / {438.5 to 724.0}/[380.6 to 628.4]

64 to 107 / {652.6 to 1091}/[566.4 to 947.0]

71 to 118 / {724.0 to 1203}/[628.4 to 1044]

94 to 157 / {958.5 to 1601}/[831.9 to 1390]

101 to 168 / {1030 to 1713}/[893.9 to 1487]

147 to 245 / {1499 to 2498}/[1301 to 2168]

—

—

—

—

—

—

—

—

—

—

51 to 85 / {520.1 to 866.8}/[451.4 to 752.3]

82 to 137 / {836.2 to 1397}/[725.7 to 1213]

—

—

—

—

—

—

—

—

—

—

—

—

—

—

61 to 102 / {622.0 to 1040}/[539.9 to 902.7]

65 to 108 / {662.8 to 1101}/[575.3 to 955.8]

84 to 141 / {856.6 to 1438}/[743.4 to 1248]

81 to 136 / {826.0 to 1387}/[716.9 to 1204]

98 to 163 / {999.3 to 1662}/[867.3 to 1443]

117 to 195 / {1193 to 1988}/[1035 to 1076]

180 to 300 / {1835 to 3059}/[1593 to 2655]

177 to 294 / {1805 to 2998}/[1567 to 2602]

254 to 423 / {2590 to 4313}/[2248 to 3744]

277 to 462 / {2825 to 4711}/[2542 to 4089]

268 to 446 / {2733 to 4548}/[2372 to 3947]

243 to 406 / {2478 to 4140}/[2151 to 3593]

331 to 551 / {3375 to 5619}/[2929 to 4877]

376 to 626 / {3834 to 6383}/[3328 to 5540]

542 to 903 / {5527 to 9208}/[4797 to 7992]

406 to 677 / {4140 to 6904}/[3593 to 5992]

2200 (88)

600 (24)

500 (20)

700 (28)

800 (32)

900 (36)

1000 (40)

1100 (44)

1200 (48)

1350 (54)

1500 (60)

1600 (64)

1800 (72)

2000 (80)

2400 (96)

2600 (104)

Gasket types

for user's

Gasket types

within

Size

mm (inch)

Flange ratings

Tab.3.3.19.EPS