Yokogawa ADMAG AXF User Manual

Page 126

IM 01E20D01-01E

8-10

8. EXPLOSION PROTECTED TYPE INSTRUMENT

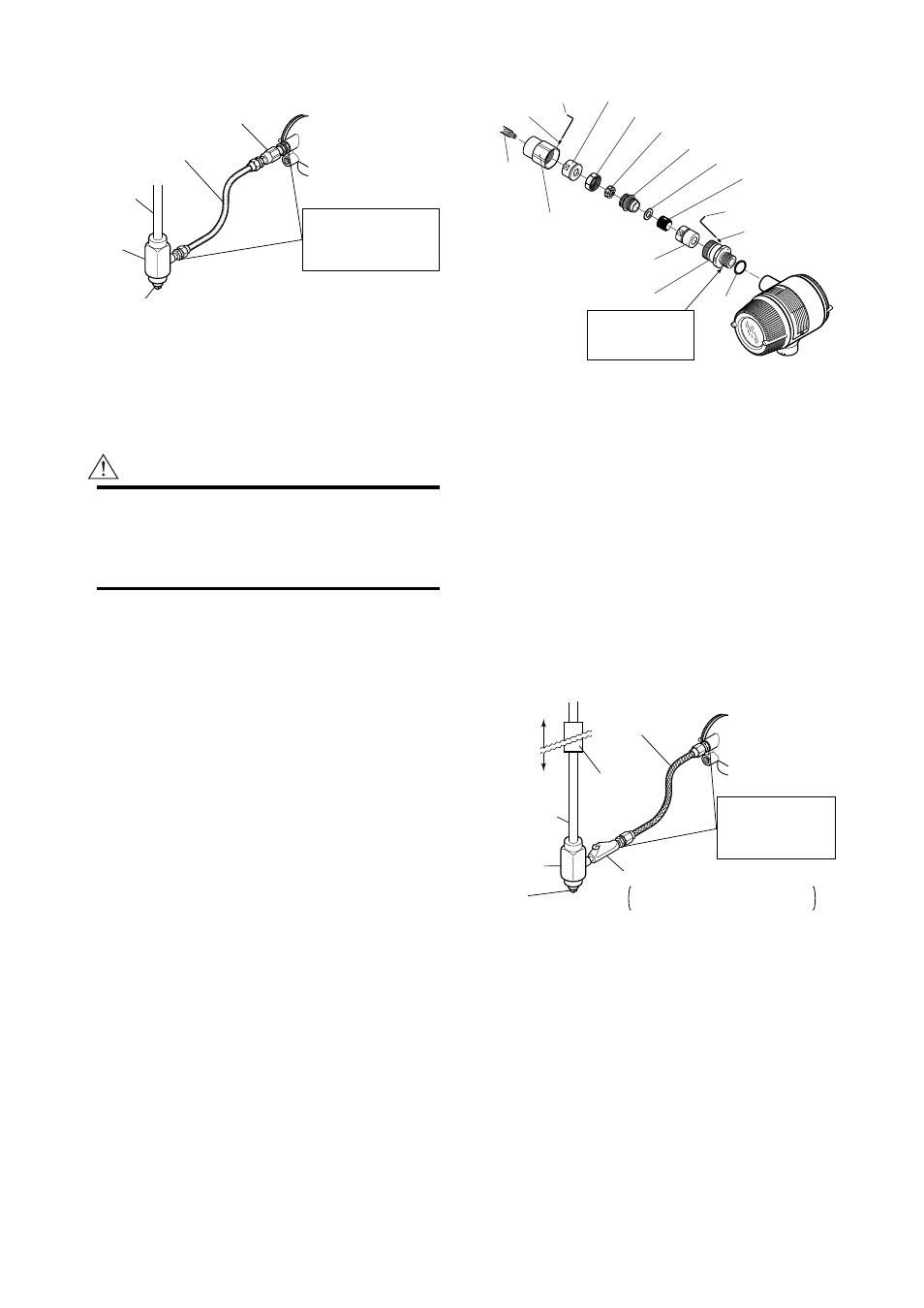

Flameproof

packing adapter

Wiring metal

conduit

Flexible metal conduit

Tee

Drain plug

F0810.EPS

Apply a non-hardening

sealant to the threads

for waterproofing.

Figure 8.4.2

Typical Wiring Using Flexible Metal Conduit

Follow the procedure for flameproof packing adapter

setting. (refer to Figure 8.4.3)

CAUTION

Before fighting, confirm cable length from

terminal to flameproof packing adapter when

setting. Once it is tightened, loosening and re-

tightening may damage its sealing performance.

(a) Loosen the locking screw and remove the terminal

box cover.

(b) Measure the cable outer diameter in two directions

to within 0.1 mm.

(c) Calculate the average of the two diameters, and use

packing with an internal diameter nearest to this

value (see the table of Figure 8.4.1).

(d) Screw the flameproof packing adapter into the

terminal box until the O-ring touches the wiring

port (at least 6 full turns), and firmly tighten the

lock nut.

(e) Insert the cable through the union cover, the union

coupling, the clamp nut, the clamp ring, the gland,

the washer, the rubber packing, and the packing

box, in that order.

(f) Insert the end of the cable into the terminal box.

(g) Tighten the union cover to grip the cable. When

tightening the union cover, tighten approximately

one turn past the point where the cable will no

longer move up and down.

Proper tightening is important. If it is too tight, a

circuit break in the cable may occur; if not tight

enough, the flameproof effectiveness will be

compromised.

(h) Fasten the cable by tightening the clamp nut.

(i) Tighten the lock nut on the union cover.

(j) Connect the cable wires to each terminal.

F0811.EPS

Adapter body

Rubber packing

Washer

Packing box

Gland

Clamp ring

Clamp nut

Union coupling

Union cover

Wrench

O-ring

Lock nut

Wrench

Lock nut

Cable

Apply a non-

hardnening sealant to

the threads for

waterproofing.

Figure 8.4.3

Installing Flameproof Packing Adapter

(2-2)

Cable Wiring Using Flameproof Metal

Conduit

• A seal fitting must be installed near the terminal box

connection port for a sealed construction.

• Apply a non-hardening sealant to the threads of the

terminal box connection port, flexible metal conduit

and seal fitting for waterproofing.

• The same wiring as described below is required for

both of the terminal box connection ports except

when a four-wire cable is used for power input and

signal output with DC power supply in the Integral

flowmeter.

F0812.EPS

Non-hazardous

area

Hazardous area

Flameproof

heavy-gauge

steel conduit

Tee

Drain plug

Seal fitting

Gas sealing

device

Flameproof flrxible

metal conduit

After wrining, impregnate the

fitting with a compound to seal tubing.

Apply a non-hardening

sealant to the threads

of these fittings for

waterproofing

Figure 8.4.4

Typical Wiring Using Flameproof Metal

Conduit