Yokogawa ADMAG AXF User Manual

Page 54

IM 01E20D01-01E

5-5

5. MAINTENANCE

NOTE

Always hold down the lead wire and terminal lug

when adjusting the mounting screw.

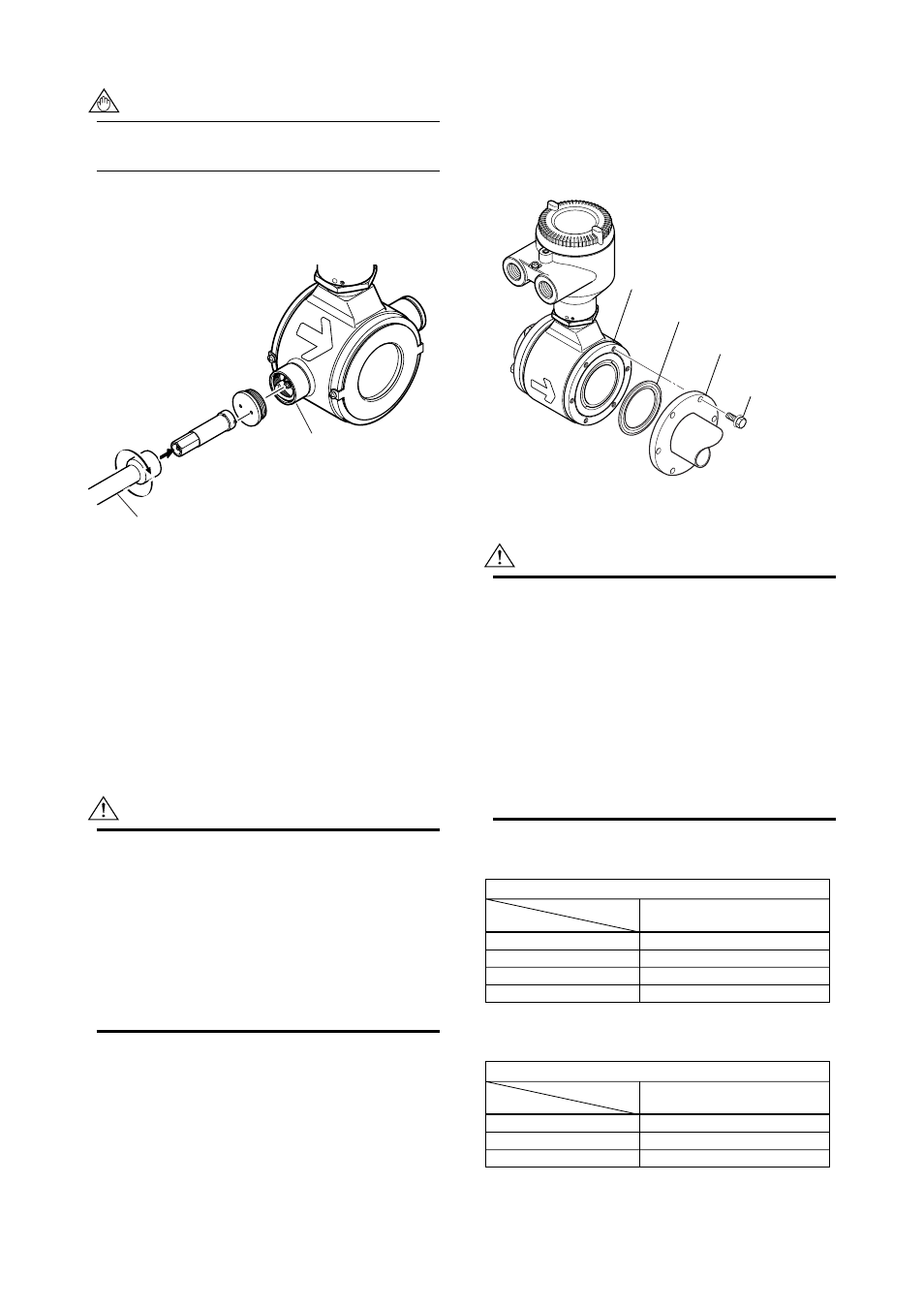

(5) Put the lead wire in the electrode boss, and install

the electrode cover to the boss and tighten it using

end A of the tool.

F0513.EPS

Torque driver

Electrode boss

(6) Turn on the power to the flowmeter and start

normal operation.

5.3 Removing and In-

stalling Adapters for

Sanitary Types

CAUTION

• This section describes how to remove and

install a butt weld adapter as an example.

Apply the same procedure to clamp and union

adapters.

• Turn off the power of the magnetic flowmeter,

and confirm that there is no fluid inside the pipe

before removing the instrument from the pipe

line.

• When installation, refer to section 3.3.6.

1) Removing the butt weld adapter

Remove the butt weld adapter by loosening the

mounting screws.

2) Installing the butt weld adapter

Install a gasket to fit in the groove of the butt weld

adapter, and tighten in the adapter with the

mounting screws.

Gasket

Mini-flange

Butt weld adapter

Adapter

mounting screw

F0316.EPS

Figure 5.3.1

Removing and Installing a Butt Weld

Adapter

CAUTION

• In case of standard gasket (EPDM rubber),

tighten the adapter mounting screw according

to the torque values in Table 5.3.1.

• In case that optional code GH (Silicon rubber)

is selected, tighten the adapter mounting screw

according to the torque values in Table 5.3.2.

• Tighten the adapter mounting screw in diagonal

order step by step.

• After tightening of screw, confirm that gaskets

protrude inside adapter. Protruding of gasket is

necessary to keep the sanitary requirements.

Table 5.3.1

Tightening Torque Values of adapter for

EPDM rubber gasket

T0502.EPS

Size mm (inch)

Gasket type

Tightening torque values (N-m / {kgf-cm} / [in-lbf])

15 (0.5), 25 (1.0), 32 (1.25), 40 (1.5)

50 (2.0), 65 (2.5)

80 (3.0)

100 (4.0), 125 (5.0)

3.0 to 3.5 / {30.59 to 35.69} / [26.55 to 30.98]

4.5 to 5.0 / {45.89 to 50.99} / [39.83 to 44.25]

8.0 to 9.0 / {81.58 to 91.78} / [70.81 to 79.65]

10 to 11 / {102.0 to 112.2} / [88.50 to 97.35]

EPDM rubber

(standard)

Table 5.3.2

Tightening Torque Values of adapter for

silicon rubber gasket

T0503.EPS

Size mm (inch)

Gasket type

Tightening torque values (N-m / {kgf-cm} / [in-lbf])

15 (0.5), 25 (1.0), 32 (1.25), 40 (1.5)

50 (2.0), 65 (2.5), 80 (3.0)

100 (4.0), 125 (5.0)

2.0 to 2.5 / {20.39 to 25.49} / [17.70 to 22.13]

4.0 to 4.5 / {40.79 to 45.89} / [35.40 to 39.83]

6.0 to 6.5 / {61.18 to 66.28} / [53.10 to 57.53]

Silicon rubber

(optional code GH)