Yokogawa ADMAG AXF User Manual

Page 33

IM 01E20D01-01E

3-23

3. INSTALLATION

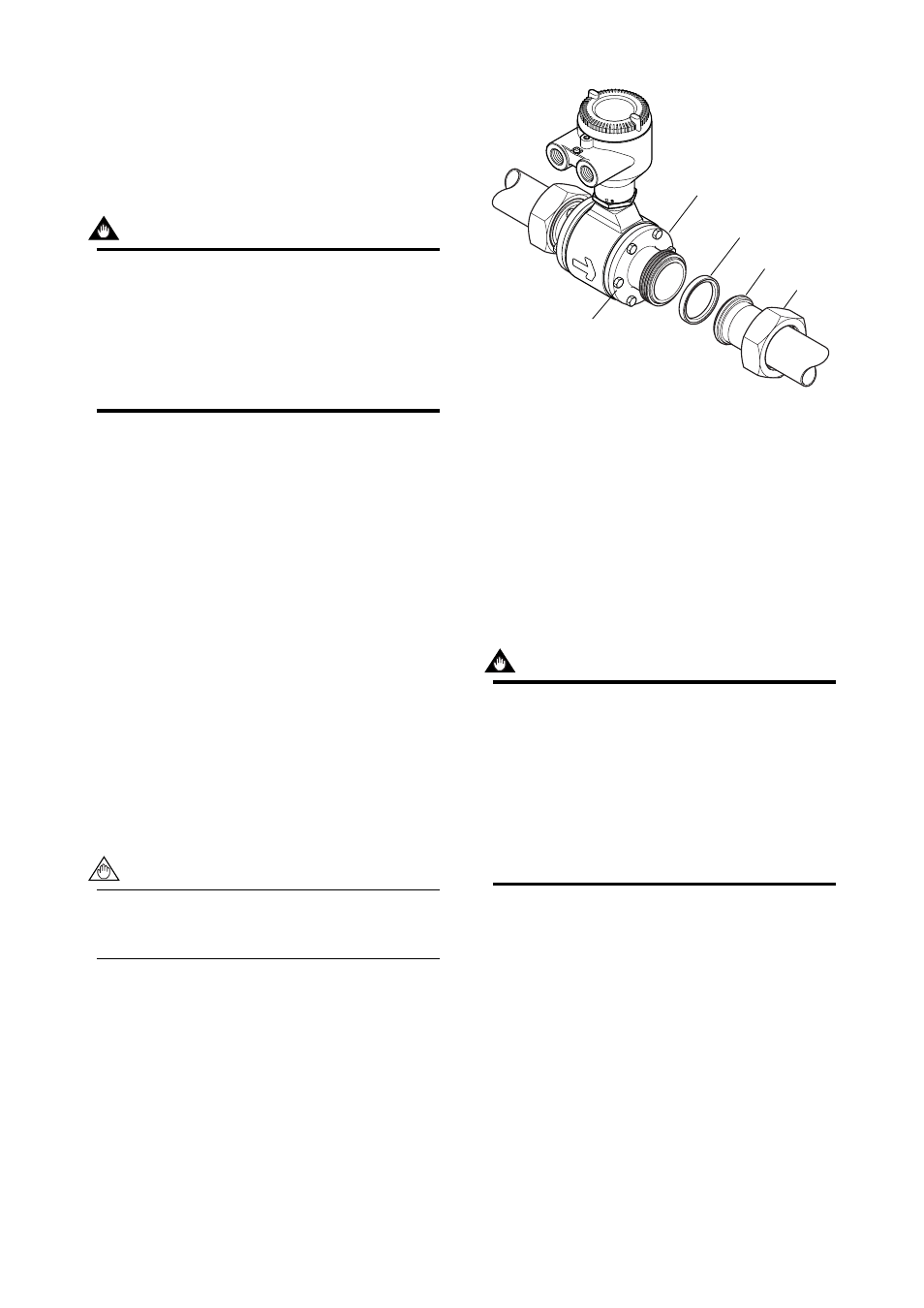

(b) Union type

(process connection codes: JDB, JKB, and JSB)

1) Welding sleeve

Pass the piping through a nut and then weld a

sleeve to the piping.

IMPORTANT

• Be sure to weld the sleeve after passing the

piping through the nut.

• When welding the sleeve, pay attention to the

edge preparation, level differences between the

sleeve and the piping, and the welding current

to avoid deforming the piping or causing

stagnation of some of the fluid.

2) Installing gasket

Install a gasket for union to fit in the groove on

the sleeve.

3) Positioning flowmeter

Move the nut closer to the piping temporarily

and position the flowmeter between the two

sleeves.

4) Tightening nut

Install the nut to cover the tapered parts of the

flowmeter-side adapter and the sleeve, and

tighten it using a wrench.

5) Confirmation of adapter mounting screw

After installation of the magnetic flowmeter, be

sure to retighten the adapter mounting screw

according to Table 3.3.21 or Table 3.3.22.

Be sure to confirm that leakage from adapter

connection point does not occur by filling the

pipe of the flowtube with fluid.

NOTE

The sleeve, nut, and gasket are not provided

with the flowmeter, and must be provided by the

user.

Gasket

Sleeve

Adapter for union connection

Nut

F0315.EPS

Adapter mounting screw

Figure 3.3.9

Mounting Procedure for Union Connection

Type

(c) Butt weld adapter type

(process connection codes: KDB and KKB)

1) Removing adapter

Remove the butt weld adapter by loosening the

mounting screws.

2) Welding ferrule or sleeve

Weld a ferrule, a sleeve, or an alternative

(provided by the user) to the butt weld adapter.

IMPORTANT

• Be sure to weld the ferrule, the sleeve, or the

alternative after removing the butt weld adapter

from the flowmeter itself.

• When welding the ferrule, the sleeve, or the

alternative, pay attention to the edge prepara-

tion, level differences between them and the

piping, and the welding current to avoid deform-

ing the piping or causing stagnation portion of

the fluid.

3) Installing butt weld adapter

Install a gasket to fit in the groove of the butt

weld adapter, and tighten the mounting screws.