2 fm, Fm -4 – Yokogawa ADMAG AXF User Manual

Page 120

IM 01E20D01-01E

8-4

8. EXPLOSION PROTECTED TYPE INSTRUMENT

8.2 FM

(1) Technical Data

*AXF002C – AXF400C

Applicable Standard:

FM3600, FM3610, FM3615,

FM3810, ANSI/NEMA 250

(Integral Flowmeter)

Explosion proof for Class I, Division 1, Groups A,

B, C & D.

Dust-ignition proof for Class II/III, Division1,

Groups E, F & G.

Intrinsically safe (electrodes) for Class I, Division 1,

Groups A, B, C & D.

“SEAL ALL CONDUITS WITHIN 18 INCHES”

“WHEN INSTALLED IN DIV. 2, SEALS NOT

REQUIRED”

Electrode Circuit Um: 250 Vac/dc

Maximum power supply voltage: 250 Vac/130 Vdc

Excitation Circuit: 140V max

Enclosure: NEMA 4X

Temperature Code: T6

Refer to following table;

T27-1.EPS

+70

°C (+158°F)

+85

°C (+185°F)

Temperature

Code

+120

°C (+248°F)

Maximum Process

Temperature

–40

°C (–40°F)

–40

°C (–40°F)

–40

°C (–40°F)

–40

°C (–40°F)

T6

Minimum Process

Temperature

T4

T5

T3

+130

°C (+266°F)

Ambient Temp.: –40

°C to +60°C (–40°F to +140°F)

(Remote Flowtube)

Explosion proof for Class I, Division 1, Groups A,

B, C & D.

Dust-ignition proof for Class II/III, Division1,

Groups E, F & G.

Intrinsically safe (electrodes) for Class I, Division 1,

Groups A, B, C & D.

“SEAL ALL CONDUITS WITHIN 18 INCHES”

“WHEN INSTALLED IN DIV. 2, SEALS NOT

REQUIRED”

Electrode Circuit Um: 250 Vac/dc

Excitation Circuit: 170V max

Enclosure: NEMA 4X

Temperature Code: T6

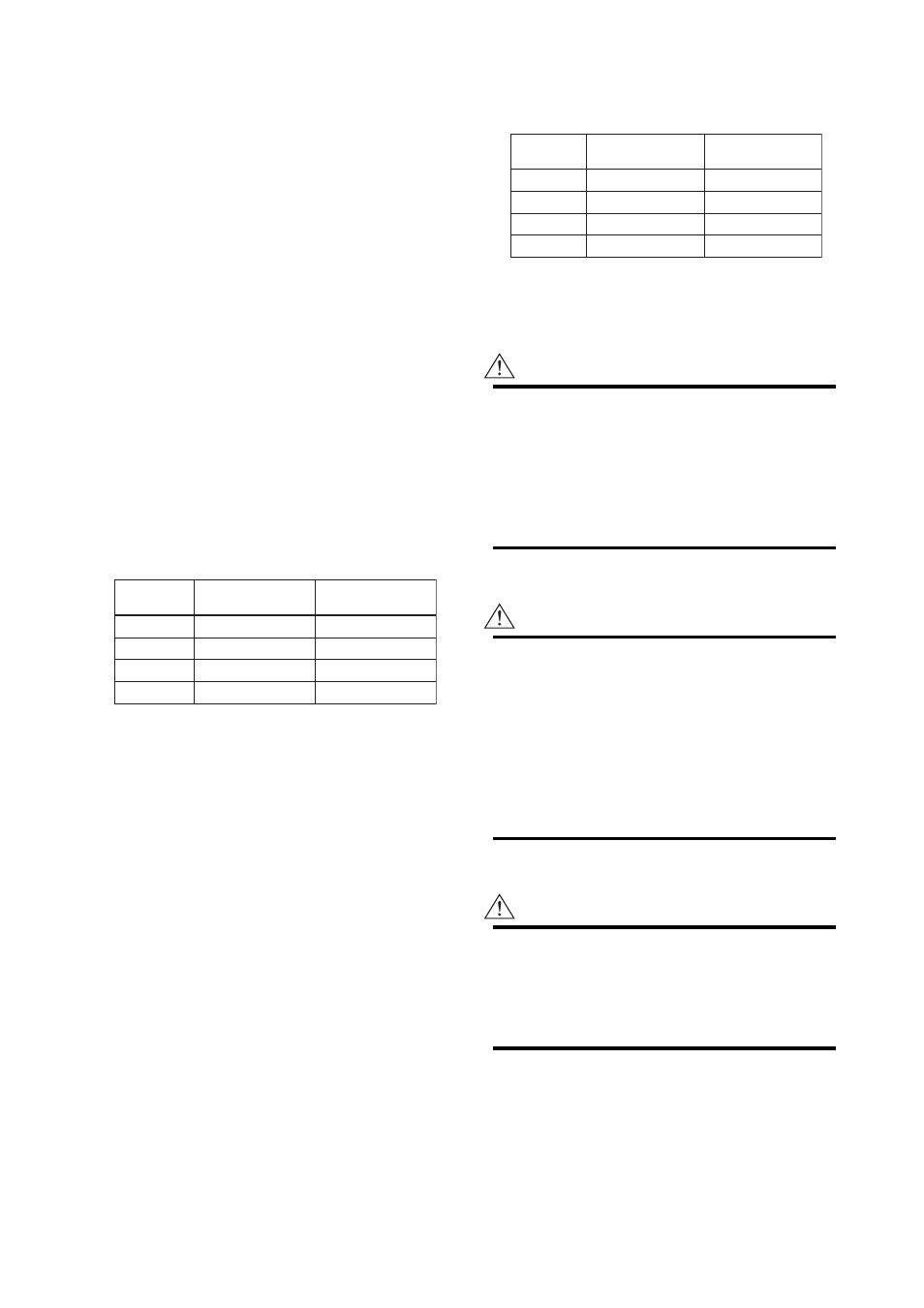

Refer to following table;

T28-1_1.EPS

Temperature

Code

Maximum Process

Temperature

–40

°C (–40°F)

–40

°C (–40°F)

–40

°C (–40°F)

–40

°C (–40°F)

T6

Minimum Process

Temperature

T4

T5

T3

+70

°C (+158°F)

+85

°C (+185°F)

+120

°C (+248°F)

+150

°C (+302°F)

Ambient Temp.: –40

°C to +60°C (–40°F to +140°F)

(2) Installation

WARNING

• All wiring shall comply with National Electrical

Code ANSI/NFPA 70 and Local Electrical

Code.

• In hazardous locations, wiring to be in conduit

as shown in Figure 8.2.1.

• When installed in Division 2, “SEALS NOT

REQUIRED”

(3) Operation

WARNING

• “OPEN CIRCUIT BEFORE REMOVING COV-

ERS.”

• “SEALS ALL CONDUITS WITHIN 18 INCHES”

in hazardous locations.

• When installed in Division 2, “SEALS NOT

REQUIRED”

• Take care not to generate mechanical spark

when access to the instrument and peripheral

devices in hazardous locations.

(4) Maintenance and Repair

WARNING

The instrument modification or parts replacement

by other than authorized representative of

Yokogawa Electric Corporation is prohibited and

will void the approval of Factory Mutual Re-

search Corporation.