Yokogawa EJX930A User Manual

Page 67

<10. General Specifications>

10-3

IM 01C25R01-01E

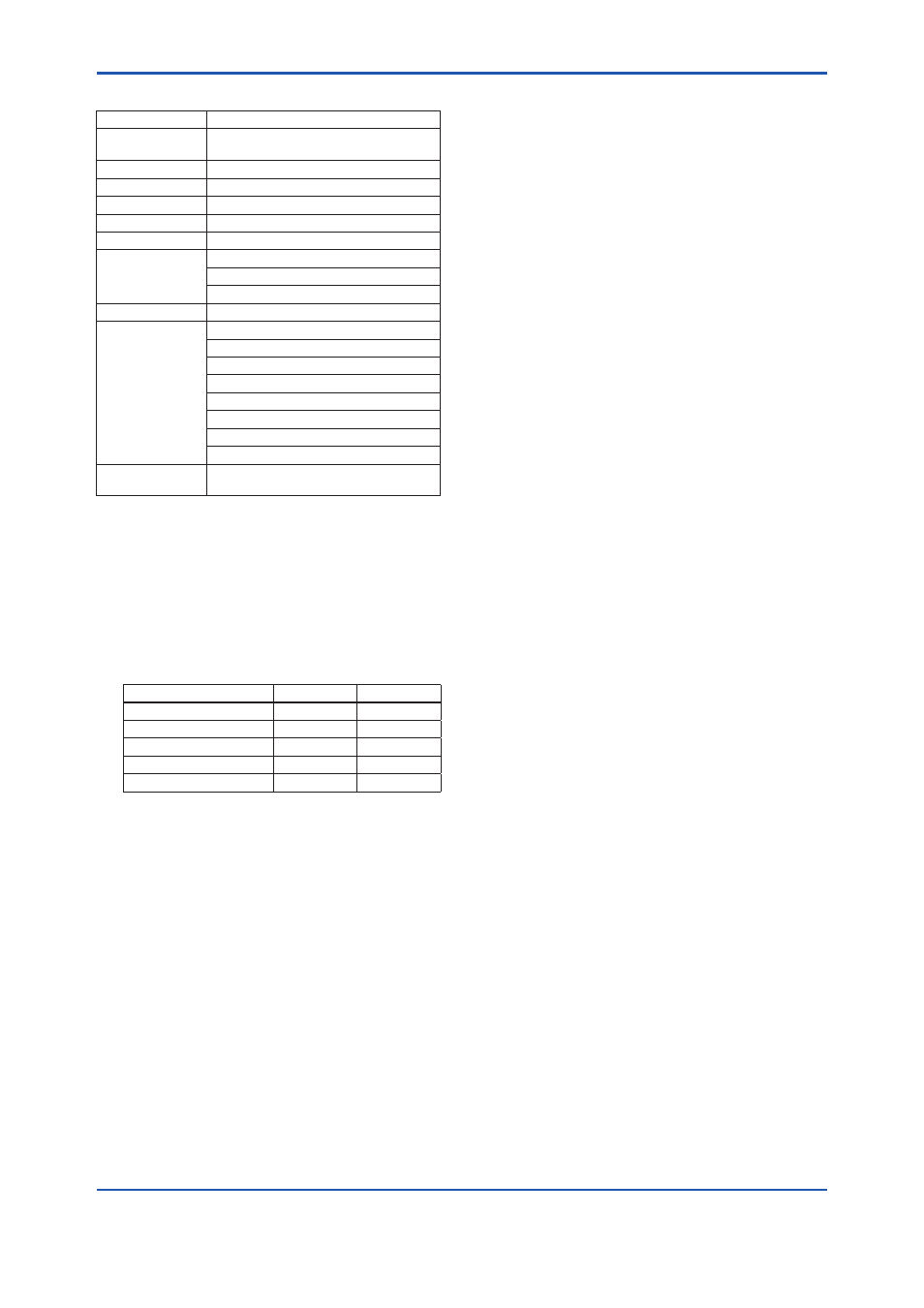

Output specifications for Modbus Protocol Type

Item

Description

Communication

protocol

2-wire half duplex RS-485 Modbus

Flow control

None

Baud rate

1200, 4800, 9600*, 19200

Start bit

1 bit (Fixed)

Stop bit

1 bit*, 2 bits

Parity bit

Odd, Even, None*

Transfer mode

RTU (Remote Terminal Unit)

Data length: 8 bits

LSB (Least significant bit sent first)

Slave address

1* to 247

Support function

1: Read Coils

2: Read Discrete Inputs

3: Read Holding Registers

4: Read Input Register

5: Write Single Coil

8: Diagnostic (00: Return Query Data)

16: Write Multiple registers

43: Read device Identification

Bus termination

Standard RS-485 bus termination

ON (bus end), OFF* (not bus end)

*:

Factory default setting

Damping Time Constant (1st order)

Amplifier damping time constant is adjustable

from 0.00 to 100.00 seconds and added to

response time, applicable independently for

“DP, SP, ET, and flow” for HART, F

OUNDATION

fieldbus and “DP, SP, and ET” for Modbus.

Update Period “◊”

Signal

HART

Modbus

Flow rate

100 ms

─

Differential pressure

100 ms

100 ms

Static pressure

100 ms

100 ms

External temperature

400 ms

400 ms

Total flow

1000 ms

─

Zero Adjustment Limits

Zero can be fully elevated or suppressed, within

the lower and upper range limits of the capsule,

applicable for DP, SP, and ET independently.

External Zero Adjustment

External zero for DP is continuously adjustable

with 0.01% incremental resolution of span.

Integral Indicator (LCD) “◊”

5-digit (Flow, DP, SP, and ET) or 6-digit (Total

flow) numerical display, 6-digit unit display and

bar graph.

The indicator is configurable to display one or

up to four variables periodically.

For Modbus, the indicator is configurable to

display up to 16 output values including RTU

output.

Burst Pressure Limits

[EJX910A] 69 MPa (10000 psi)

[EJX930A] 132 MPa (19100 psi)

Self Diagnostics

CPU failure, hardware failure, configuration

error, process alarm for differential pressure,

static pressure and external temperature.

SIL Certification (For HART protocol type)

EJX series transmitters except F

OUNDATION

Fieldbus and Modbus protocol types are

certified by TÜV in compliance with the

following standards;

IEC 61508: 2000; Part1 to Part 7

Functional Safety of electrical/electronic/

programmable electronic safety-related

systems; SIL 2 capability for single transmitter

use, SIL 3 capability for dual transmitter use.

Functions Applicable for HART Protocol

Revision 7

• Long tag supporting up to 32 characters

Long tag secures a better asset management

with abundant digits in its software.

• Enhanced burst mode and event notification

Advanced burst mode includes the variety

of transmission setting by specifying burst

variables, update period, and message trigger

mode, and event notification function gives

you alert signal based on the status change in

preset values and self-diagnosis.

• Squawk

Identifying the transmitter by displaying the

particular pattern on LCD

• Multidrop communication

Up to 63 transmitters can be connected. An analog

signal output available for one device in a loop.

Functions Applicable for Modbus Protocol

• Process data diagnosis

The process data status is provided for each

measured differential pressure, static pressure

and process temperature. Also device status

parameter is available for detail diagnosis.

• Long tag supporting up to 32 characters

Long tag secures a better asset management

with abundant digits.

• Squawk

Identifying the transmitter by displaying the

particular pattern on LCD.

• Multi-drop communication

Up to 32 transmitters can be connected.