Yokogawa EJX930A User Manual

Page 24

<3. Handling Cautions>

3-7

IM 01C25R01-01E

• Ambient Temperature for gas-proof:

–50 to 60°C

• Process Temperature (Tp.): 120°C max.

• Maximum Surface Temperature for dust-

proof:

T85°C (Tamb.: –40* to 60°C, Tp.: 80°C)

T100°C (Tamb.: –40* to 60°C, Tp.: 100°C)

T120°C (Tamb.: –40* to 60°C, Tp.: 120°C)

* –15°C when /HE is specified.

• Enclosure: IP66 and IP67

Note 2. Electrical Data

[Supply/Output circuit (terminals + and -)]

In type of explosion protection intrinsic safety

EEx ia IIC, only for connection to a certified

intrinsically safe circuit with following maximum

values:

Ui = 30 V

Ii = 200 mA

Pi = 0.9 W

Ci = 10 nF

Li = 0 mH

[Pulse Output circuit (terminals - and pulse)]

In type of explosion protection intrinsic safety

EEx ia IIC, only for connection to a certified

intrinsically safe circuit with following maximum

values:

Ui = 30 V

Ii = 200 mA

Pi = 0.9 W

Ci = 10 nF

Li = 0 mH

[External temperature input circuit (connector)]

In type of explosion protection intrinsic safety

EEx ia IIC, with following maximum values:

Uo = 30 V

Io = 95.4 mA

Po= 468 mW

Co = 11 nF

Lo= 3.9 mH

Note 3. Installation

• All wiring shall comply with local installation

requirements. (Refer to the installation

diagram)

• When the analog and pulse circuits are

connected to separate barriers, it shall be

assured that the voltage difference between

these output circuits is not more than 30 V.

• When used in a potentially explosive

atmosphere, Requiring the use of apparatus

of equipment category 1D or 2D, certified

cable entry devices shall be used that are

suitable for the application and correctly

installed.

Note 4. Maintenance and Repair

• The instrument modification or parts

replacement by other than authorized

representative of Yokogawa Electric

Corporation is prohibited and will void KEMA

Intrinsically safe Certification.

Note 5. Special Conditions for Safe Use

• In the case where the enclosure of the

Pressure Transmitter is made of aluminium,

if it is mounted in an area where the use of

category 1 G apparatus is required, it must

be installed such, that, even in the event of

rare incidents, ignition sources due to impact

and friction sparks are excluded.

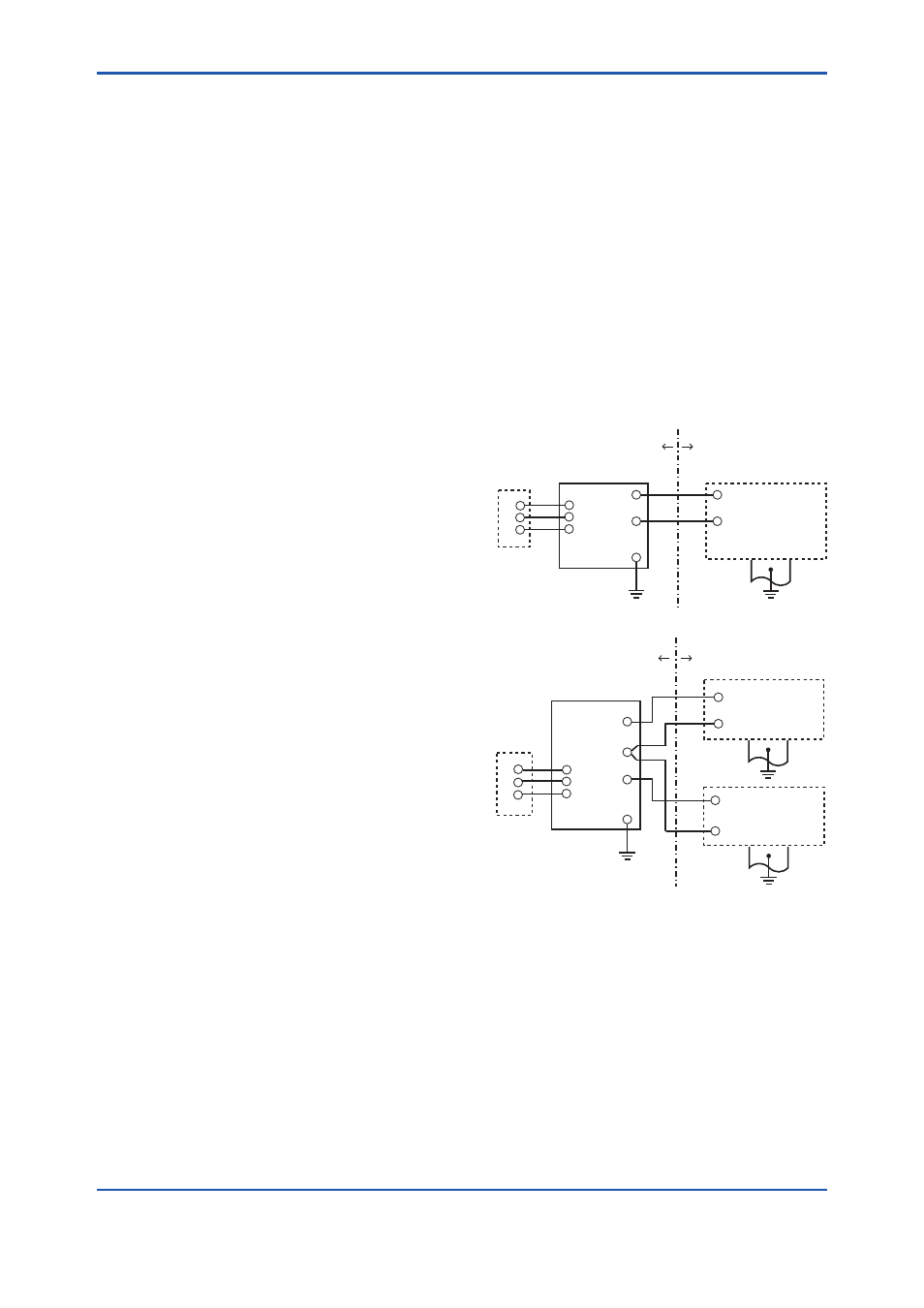

Transmitter

Supply

Safety Barrier

Nonhazardous Location

[Installation Diagram]

Hazardous Location

+

–

+

–

F0305.ai

(*1)

Note 1

Sensor out

RTD sensor

Note 2

Without pulse output

With pulse output

Transmitter

Supply

Safety Barrier

Nonhazardous Location

Hazardous Location

+

–

+

–

+

(*1)

Note 1

Sensor out

RTD sensor

Note 2

Safety Barrier

+

–

(*1)

Note 1

Pulse

Note 1:

• In any safety barriers used the output current must be

limited by a resistor “R” such that Io=Uz/R.

• The safety barrier shall be certified by notify body EU

as ATEX.

• When using non isolation barrier, connect (*1) to IS

earthing system.

Note 2:

• RTD sensor is prepared by the user.

• The sensor signal line must withstand a test voltage of

500 V AC.