2 routing the impulse piping, Routing the impulse piping -2 – Yokogawa EJX930A User Manual

Page 35

<6. Installing Impulse Piping>

6-2

IM 01C25R01-01E

4) Now tighten the nuts and bolts securely in the

following sequence:

Process connector bolts → transmitter-end ball

head lock nuts → 3-valve manifold ball head

lock nuts → 3-valve manifold mounting bracket

U-bolt nuts

F0602.ai

Nipple

Nipple

Process

connector

Ball head

lock nut

Pipe

Ball head

lock nut

Process

connector bolts

50 mm(2-inch) pipe

Pipes

3-valve

manifold

Impulse piping

Vent plug

(optional)

Stop valve

(low pressure side)

Equalizing valve

(balancing)

Stop valve

(high pressure side)

Figure 6.2

3-Valve Manifold (Pipe-Mounting Type)

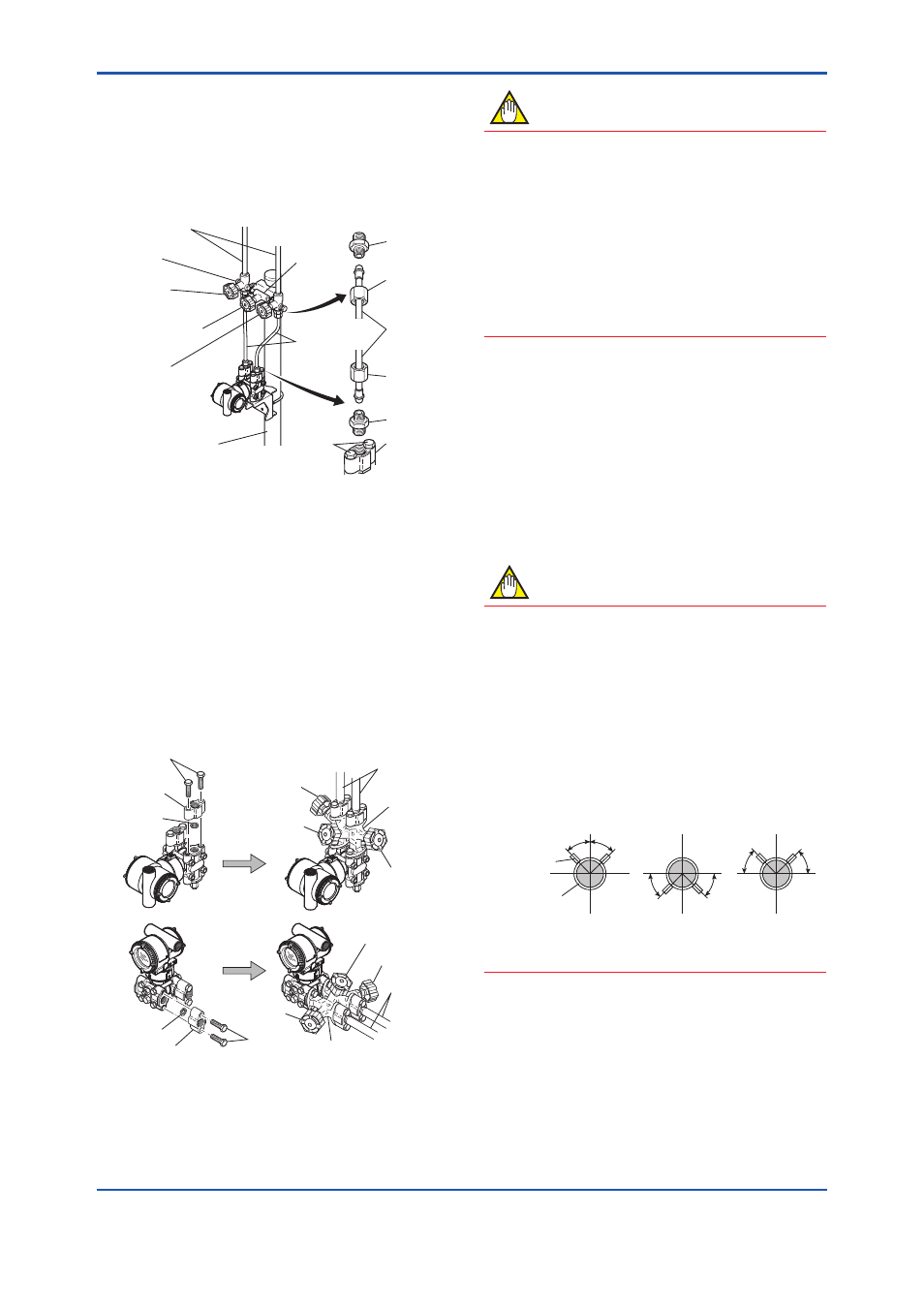

Direct-Mounting Type 3-Valve Manifold

(Figure 6.3)

1) Mount the 3-valve manifold on the transmitter.

(When mounting, use the two gaskets and the

four bolts provided with the 3-valve manifold.

Tighten the bolts evenly.)

2) Mount the process connectors and gaskets

on the top of the 3-valve manifold (the side on

which the impulse piping will be connected).

F0603.ai

Bolts

Process

connector

Gasket

Gasket

Process

connector

Bolts

Stop valve

Stop valve

3-valve

manifold

3-valve

manifold

Equalizing valve

Equalizing

valve

Stop valve

Impulse

piping

Impulse

piping

Stop valve

Figure 6.3

3-Valve Manifold (Direct-Mounting

Type)

NOTE

After completing the connection of the transmitter

and 3-valve manifold, be sure to CLOSE the low

pressure and high pressure stop valves, OPEN

the equalizing valve, and leave the manifold with

the equalizing valve OPEN.

You must do this in order to avoid overloading

the transmitter from either the high or the low

pressure side when beginning operation.

This instruction must also be followed as part of

the startup procedure (chapter 8.)

6.1.2 Routing the Impulse Piping

(1) Process Pressure Tap Angles

If condensate, gas, sediment or other extraneous

material in the process piping gets into the impulse

piping, pressure measurement errors may result. To

prevent such problems, the process pressure taps

must be angled as shown in figure 6.4 according to

the kind of fluid being measured.

NOTE

• If the process fluid is a gas, the taps must be

vertical or within 45° either side of vertical.

• If the process fluid is a liquid, the taps must

be horizontal or below horizontal, but not

more than 45° below horizontal.

• If the process fluid is steam or other

condensing vapor, the taps must be

horizontal or above horizontal, but not more

than 45° above horizontal.

[Gas]

Pressure

taps

Process

piping

[Steam]

[Liquid]

45°

45°

45°

45°

45°

45°

F0604.ai

Figure 6.4

Process Pressure Tap Angle (For

Horizontal Piping)