General software – Watlow Series 988 User Manual

Page 137

WATLOW Series 988 User’s Manual

8.23

General Software Features, Chapter 8

TL

TL

W

W

W

WA

A

PROCESS

L1

L2

L3

L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

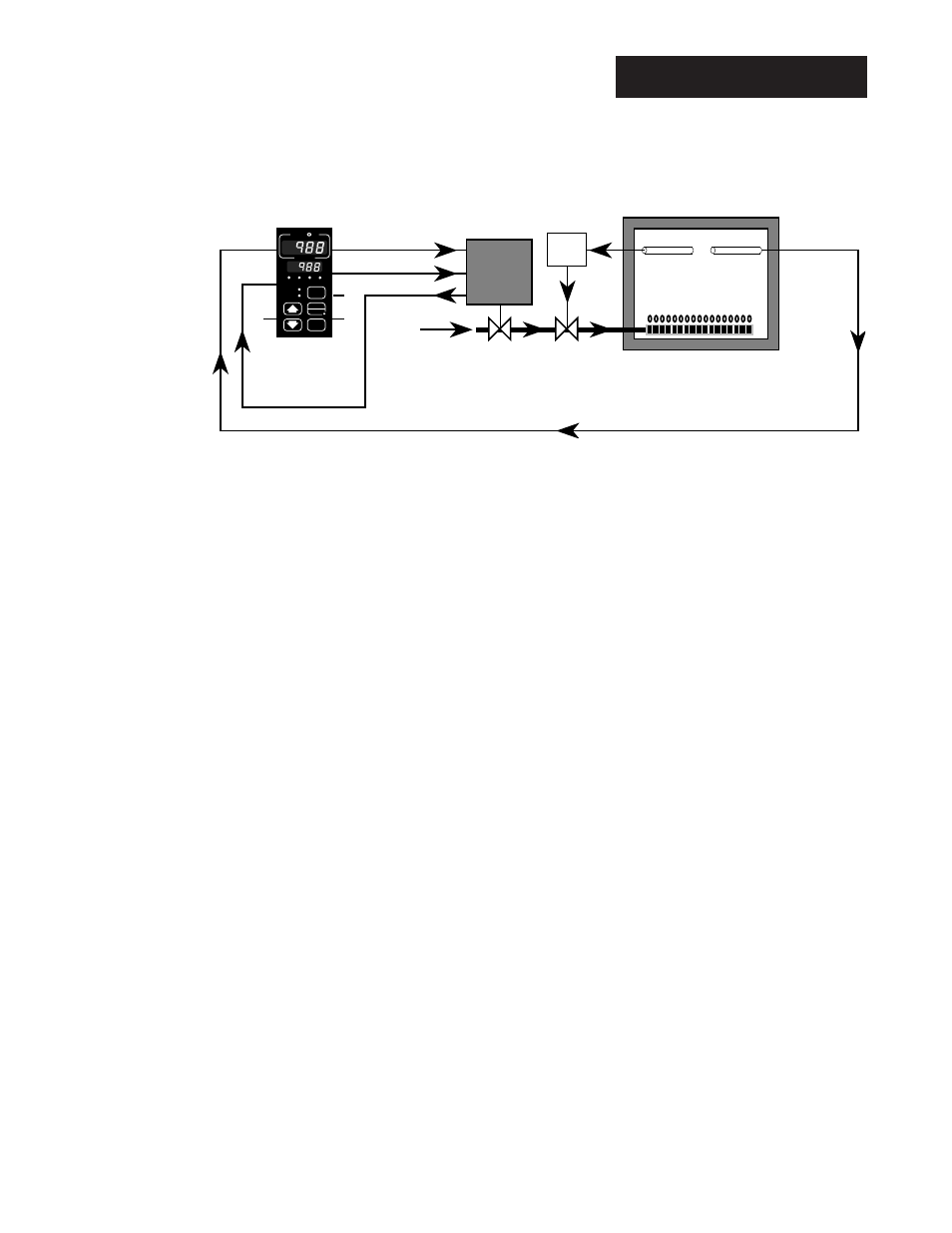

input 1

input 2

slidewire input

output 1 (close)

output 2 (open)

gas

flow

gas valve

cut-off

valve

Valve Actuator

limit

Gas-fired Furnace

limit

sensor

temperature

sensor

Sample Application

A Series 988 controls the gas valve for a gas-fired furnace to heat treat

large metal parts. First the controller must be “married” to the slidewire

feedback from the valve actuator. To do this, first set the Input 2 prompt

[`In2] to slidewire [Slid]. Advance to the Learn Low Resistance prompt

[LrnL]. Close the valve manually to the minimum resistance reading from

the slidewire. Select [`yes] in the upper display and press the Mode key

µ to advance to the Learn High Resistance prompt [LrnH]. Manually

open the valve (maximum slidewire resistance). Select [`YES] in the upper

display and press the Mode key µ. At this point both the high and low

resistance values have been learned and stored in the range low 2 and

range high 2 parameters.

You can also manually set the range low and range high values. From the

slidewire specifications, determine the low and high resistance values and

enter these at the Range Low [`rL2] and Range High [`rH2] prompts.

Once the control is operating, adjust the hunt [hunt] parameter, to mini-

mize valve oscillations. The hunt parameter sets up a dead band on both

sides of the current valve position. The desired valve position is then com-

pared to the actual position. If the difference is greater than the one-half of

the hunt value, the Series 988 repositions the valve to achieve the temper-

ature set point. Once repositioning is complete, the dead band is recalcu-

lated for the new valve position.

Figure 8.23 -

Gas-fired furnace

with slidewire feed-

back.

General Software