Diagnostics, Standard features – Watlow Optimizing Your Process System with the Series 988 Controller User Manual

Page 45

Standard Features

5.5

Optimizing Your Process System with the WATLOW Series 988

Diagnostics

Overview:

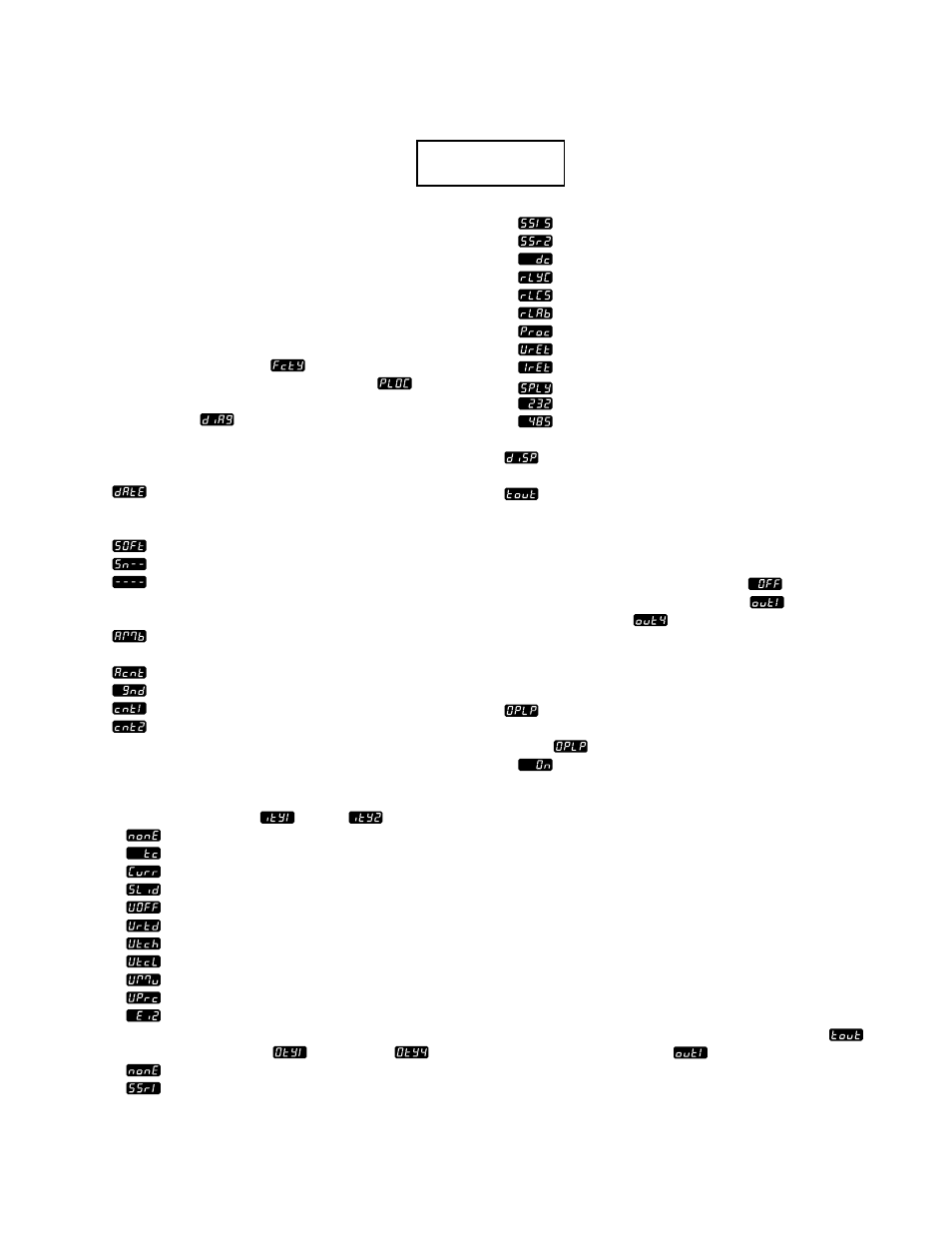

The Series 988 Diagnostics menu allows you to

read the software revision, ship date, hardware

configuration and ambient temperature without

removing power from the control.

To access the Diagnostics menu press the

increment (up-arrow) and decrement (down-

arrow) keys simultaneously for six seconds.

The factory prompt

appears in the lower

display and panel lockout prompt

in the

upper display. Press the increment key until

diagnosis

appears in the upper display.

Then press the MODE key.

The list below explains the menu prompts:

Date provides the date of the final control

test. The first two numbers indicate the week

(01 through 52) and the last two show the year.

Soft signifies the control software revision.

The serial number follows “Sn” in the upper

display. The six-digit number begins with

the last two digits in the upper display and

wraps around to the lower display.

Ambient temperature indicates the tem-

perature at the input 1 terminals, in degrees F.

Ambient counts is for factory use only.

Ground counts is for factory use only.

Input 1 counts is for factory use only.

Input 2 counts is for factory use only.

Depending on the modules installed and the

DIP switch settings, some of the following input

and output type displays will appear:

Types for Inputs 1

and 2

no module

thermocouple only

current detect

slidewire

universal OFF

universal RTD

universal tc high gain

universal tc low gain

universal millivolts

universal process

event input 2

Types for Outputs 1

through 4

no module

0.5A SSR

0.5A SSR w/ suppression

2.0A SSR

switched DC

form C relay

form C relay w/ suppression

form A/B Relay

process

voltage retransmit

current retransmit

power supply

RS-232 communications

EIA-485/422 communications

Display tests each display and LED. If any

display or LED is absent contact the factory.

The test output prompt can be used to

activate the available outputs on the unit, with

the exception of process outputs, transmitter

power supply or communications output. To

select an output, use the increment or decre-

ment key to advance from OFF

to the

desired output (output 1 active

through

output 4 active

). After three seconds the

corresponding load LED will light and the

output will be energized. This output will

remain energized until you select another

output or off, or exit the Diagnostic menu.

The open loop prompt enables the open-

loop error function. The error message open

loop

flashes in the lower display when ON

is selected and a heat or cool output is

full on and no temperature change has oc-

curred over a period of time, based on system

characteristics. This prompt only functions in

the proportional control mode.

Requirements:

The Diagnostics menu is a standard feature on

all Series 988 controllers. When asking the

factory for technical assistance, have the

information from the above prompts on hand.

All prompts in this menu are read only.

Sample Application:

An engineer needed to figure out why an oven

was malfunctioning. She used test output

to force ON output 1

, which controlled the

heaters. A quick check with a meter revealed a

burned out heater element.