Cascade, Enhanced software features – Watlow Optimizing Your Process System with the Series 988 Controller User Manual

Page 35

Optimizing Your Process System with the WATLOW Series 988

Enhanced Software Features

4.2

Cascade

Overview

Cascade control can handle a difficult process

with minimal overshoot, while reaching the set

point quickly. This minimizes damage to

system components and allows for oversizing

heaters for optimal heat-up rates.

Systems with long lag times between the energy

source (heater, steam, etc.) and the measured

process value cannot be controlled accurately

or efficiently with a single control loop, because

a lot of energy can build up before a response

is detected. This can cause the system to

overshoot the set point, which could damage

the heater, product or heat transfer medium,

such as a heat transfer fluid.

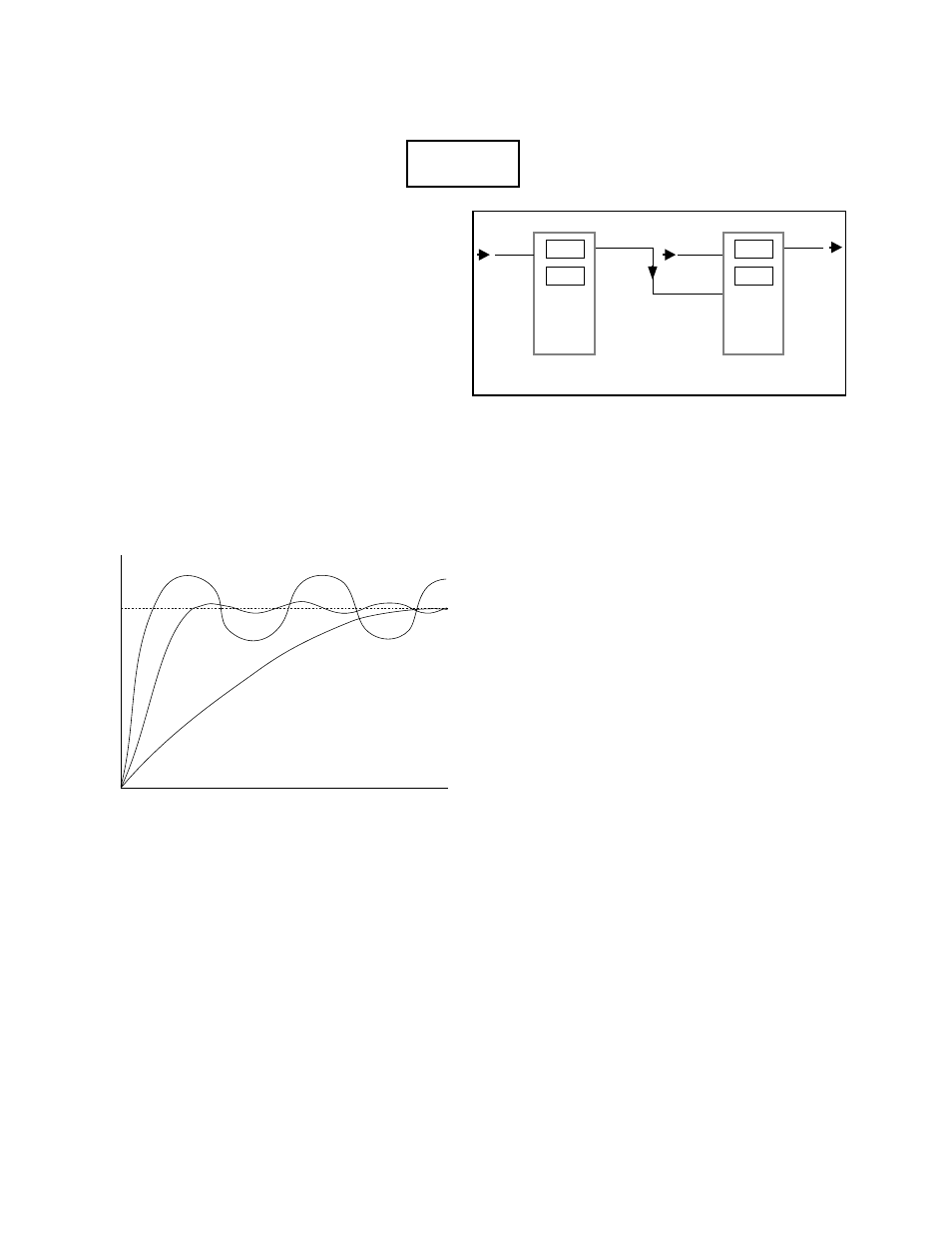

This graph illustrates a system with a long lag

time. Curve A represents a single-control

system with PID parameters that allow a

maximum heat-up rate. Too much energy is

introduced and the set point is overshot. In

most long-lag-time systems the process value

may never settle out to an acceptable error.

Curve C represents a single-control system

tuned to minimize overshoot. This results in

unacceptable heat-up rates, with the final

value taking hours to reach. Curve B shows a

cascade system that limits the energy intro-

duced into the system, allowing an optimal

heat-up rate with minimal overshoot.

This drawing shows two controllers configured

as a cascade system. The second controller

input 1

input 2

output 1

Outer-loop

Controller

Inner-loop

Controller

%

out

%

int

In1

SP

In2

SP

int

The cascade feature allows the Series 988 to internalize the func-

tions of two controllers

generates the internal set point. The Series 988

effectively combines both controllers into a

single package.

The primary controller measures the process in

the outer, or primary, loop with input 1 and

compares the value to the desired set point.

The difference between the set point and the

process temperature generates an internal

percent output value for the second controller.

This value cannot be seen by the operator. This

internal percent (%

int

) output generates the

internal set point for the secondary, or inner

loop. The secondary loop uses this set point

and the value of input 2 (typically attached to

the heater sheath) to control the heater tem-

perature.

Algorithm

The following formulas show how the primary

control sends a set point (based on input 2

range-high and range-low values) to the sec-

ondary control. The secondary control uses this

set point (SP

int

) to generate a percent output

(%

out

) to the heater.

1.) %

int

= PID Set A[In1 - SP]

2.) SP

int

= (rH2 - rL2) * %

int

+ rL2

3.) %

out

= PID Set B[In2 - SP

int

]

The critical parameters are the range settings

for input 2 of the second controller. The range-

high value (rH2) is the maximum allowed set

point for the secondary loop. The range-low

value (rL2) is the minimum allowed set point.

A

B

C

time

→

set point

Two controllers in one