Basic control strategies and terms – Watlow Optimizing Your Process System with the Series 988 Controller User Manual

Page 13

Optimizing Your Process System with the WATLOW Series 988

Basic Control Strategies and Terms

2.3

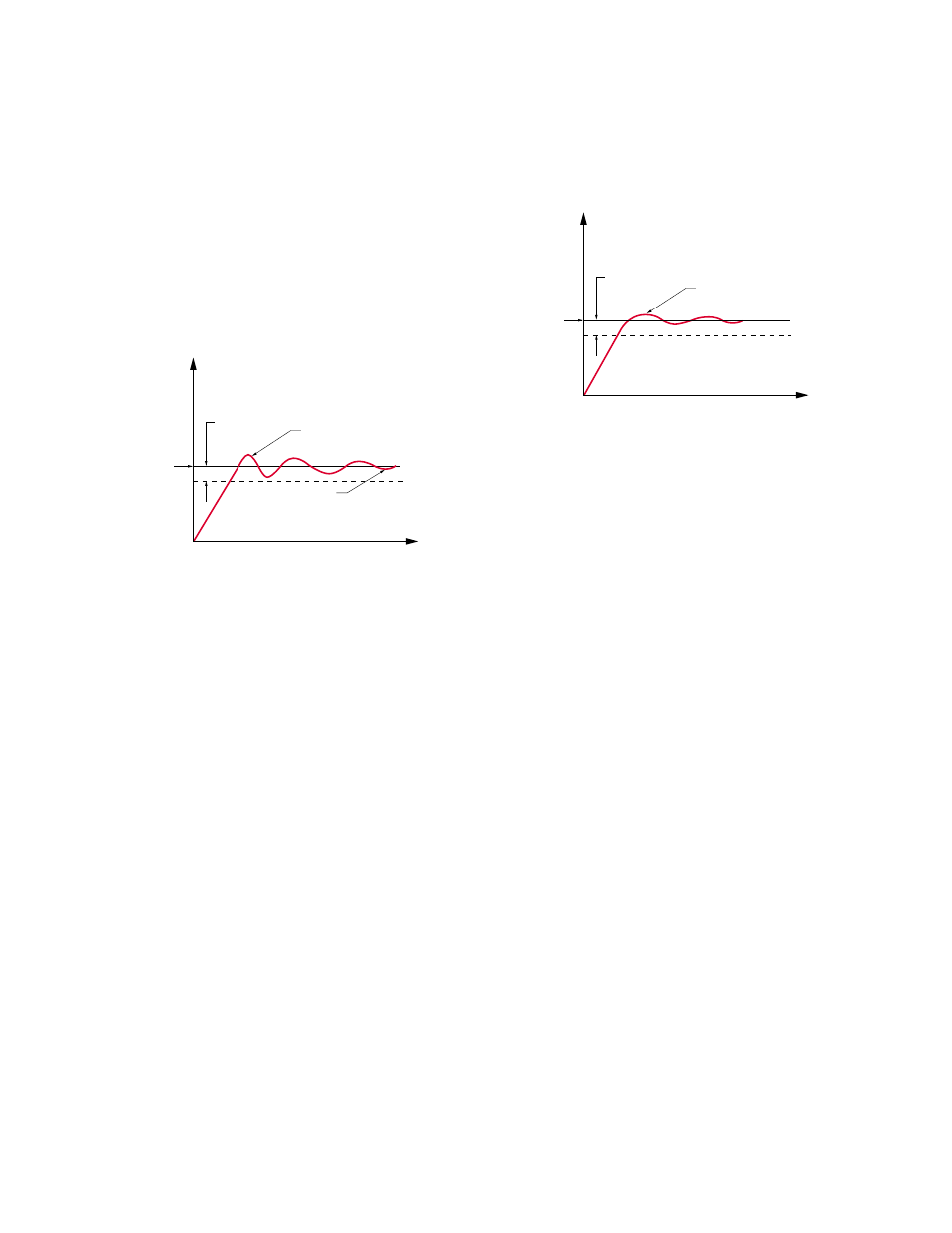

a droop condition before it exists. An integra-

tion function takes place that automatically

compensates for the difference between set

point and the actual process. This integration

automatically drives the process toward set

point. Integration action is prevented until the

process enters the proportional band. If it was

Proportional

Band

Time Proportioning

With Automatic Reset

Time

Temperature

Set

Point

Droop

Overshoot

Proportional

Band

PID -Time Proportioning

With Auto Reset & Rate

Time

Temperature

Set

Point

Reduced Overshoot

allowed to take place at any point, it would

cause a condition of extreme overshoot. This

function of eliminating the integration outside

of the proportional band is referred to as “anti-

reset windup.”

Derivative

As all of the graphs have illustrated, overshoot

occurs with any of the previous control meth-

ods. Overshoot may be hazardous to certain

processes. It is preventable with a control

function known as “derivative” (rate).

Derivative is an anticipatory function in a

process control that measures the rate of

change of the process and forces the control

into a proportioning action on an accelerated

basis to slow that change. This action prevents

a large degree of overshoot on start-up and also

functions to prevent overshoot when system

disturbances would tend to drive the process

up or down. A proportioning control with

integral and derivative (PID) control provides

the type of control required for difficult pro-

cesses with frequent system disturbances or

applications that need precision control.

Control System Tuning

In this phase of making the system work, we

will focus on the process controller as the

primary component of a closed-loop system

that must be adjusted for optimum perfor-

mance. These adjustments provide a means to

compensate for system problems. For instance,

when the sensor cannot be placed in the most

desirable location because of physical limita-

tions, a PID controller can compensate for the

sensor’s resulting thermal lag problem.

Tuning Methods

Process controls are tuned manually or auto-

matically. Manual tuning requires manually

setting each of the controller’s operating pa-

rameters. Automatic tuning, or auto-tuning, is

accomplished by the 988’s digital, microproces-

sor-based, electronic circuitry. The controller

uses a program inside its memory that will

calculate the correct setting for each of the

controller parameters. For more information on

auto-tuning with the Series 988 refer to page

3.2.

Manual Tuning

The following steps are generally applicable to

most manually set process controllers. Please

take note of a few precautions:

• Take your time in tuning the control system.

If you do it right, it will work a long time

without further attention.

• Do not change more than one control adjust-

ment at a time, allowing the system to settle

Profile developed by a proportional plus

integral plus derivative (PID) control

Profile developed by a proportional plus

integral control