Communications, General software features, Process – Watlow Optimizing Your Process System with the Series 988 Controller User Manual

Page 24: Series 988

Optimizing Your Process System with the WATLOW Series 988

General Software Features

3.4

Communications

Overview

The serial communications feature allows the

Series 988 family to receive commands from

and transmit data to a master device, usually a

computer. Any function that can be performed

via the front panel, can also be accomplished

using the serial communications port, allowing

you to operate the controller from a computer

and to store process data on a computer.

The 988 is available with a choice of serial

hardware interfaces. An RS-232 interface

allows for one master (computer) and one

controller, with a maximum network length of

50 feet (15 meters).

The EIA-485/RS-422 option equips the control-

ler for a multi-drop interface: up to 32 total

network devices with EIA-485 and up to 10

total network devices with RS-422. Each

controller will have its own unique address.

The total maximum network length is 4,000

feet (1,219 meters). These are isolated inter-

faces.

To select between EIA-485 or RS-422, enter the

setup prompts by holding the increment (up-

arrow) and decrement (down-arrow) keys

simultaneously until setup

appears in the

bottom display. Use the decrement key to select

the Communications menu

. The interface

prompt

selects between 485 or 422.

Other parameters that must be configured in

the Communications menu

are the baud

rate

, data bits and parity

, protocol

, and device address

. The protocol

prompt must be set to full

(ANSI

X3.28 2.2-A3) if multiple devices are used with

the EIA-485 or RS-422 interface. If the full

protocol is selected, a device address must be

selected at the address prompt

. For RS-

232, full

or on

(XON/XOFF) protocol

may be selected.

Requirements

Choose which interface your application will

use: RS-232 serial communications; EIA-485;

or RS-422 serial communications. The com-

puter must have a compatible serial port.

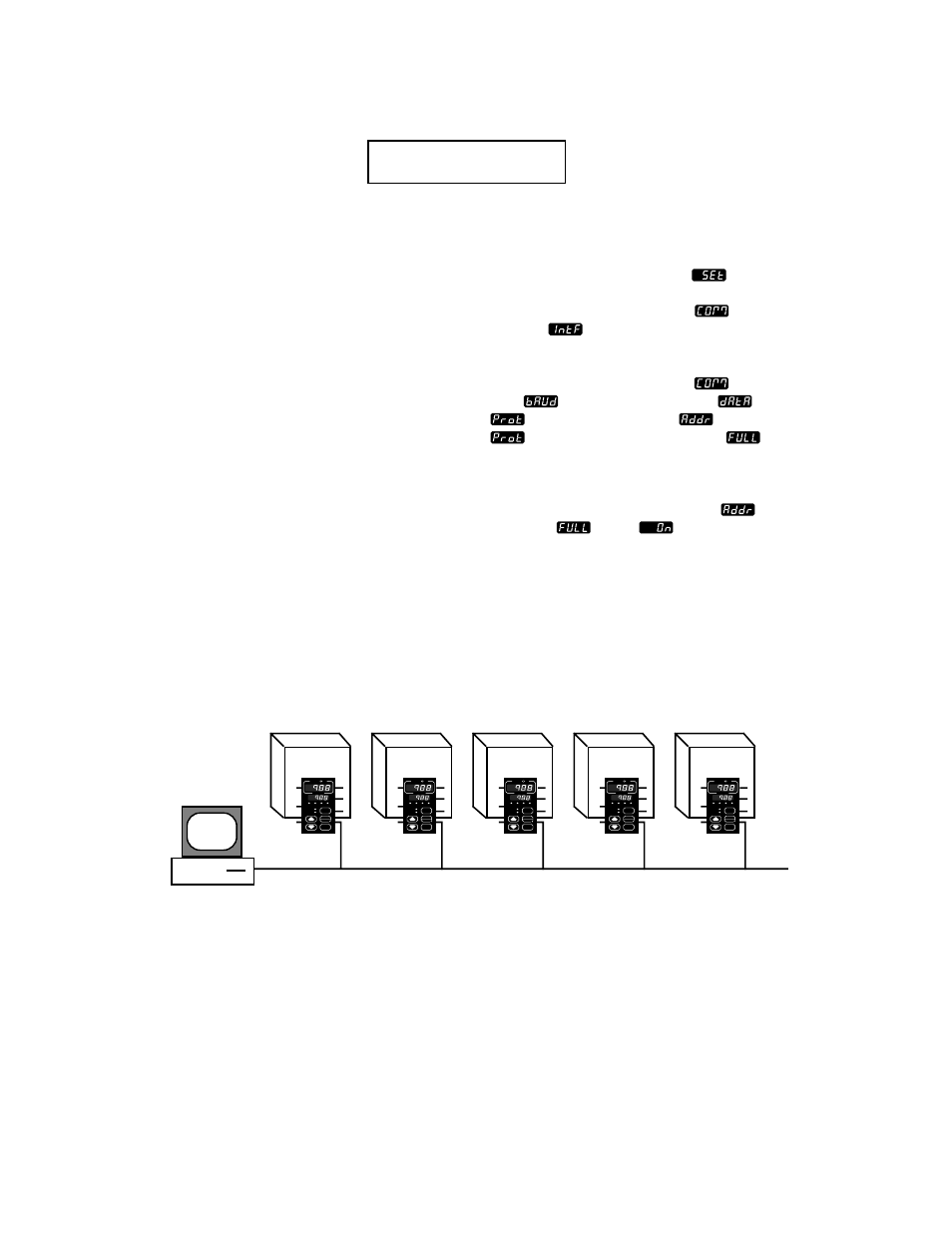

Sample Application

A test engineer uses 988’s to control the temperatures of several automated

test chambers. His computer is linked to the controllers through its RS-422

serial communications port. His computer program monitors the tempera-

tures of the 988’s and initiates automatic test sequences when certain pro-

gram parameters have been met. After completing a sequence, the computer

loads the next temperature to the controller. The computer periodically

interrogates each controller for its process temperature, set point and alarm

status. This information is stored on a disk to provide test verification data for

the completed products.

TL

TL

W

WA

PROCESS

L1

L2

L3

L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

TL

TL

W

WA

PROCESS

L1

L2

L3

L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

TL

TL

W

WA

PROCESS

L1

L2

L3

L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

TL

TL

W

WA

PROCESS

L1

L2

L3

L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

TL

TL

W

WA

PROCESS

L1

L2

L3

L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

Test

Chamber 1

Test

Chamber 2

Test

Chamber 3

Test

Chamber 4

Test

Chamber 5

output 4

output 4

output 4

output 4

output 4

Personal Computer

with RS-422 port