Heater current, General software features – Watlow Optimizing Your Process System with the Series 988 Controller User Manual

Page 27

General Software Features

3.7

Optimizing Your Process System with the WATLOW Series 988

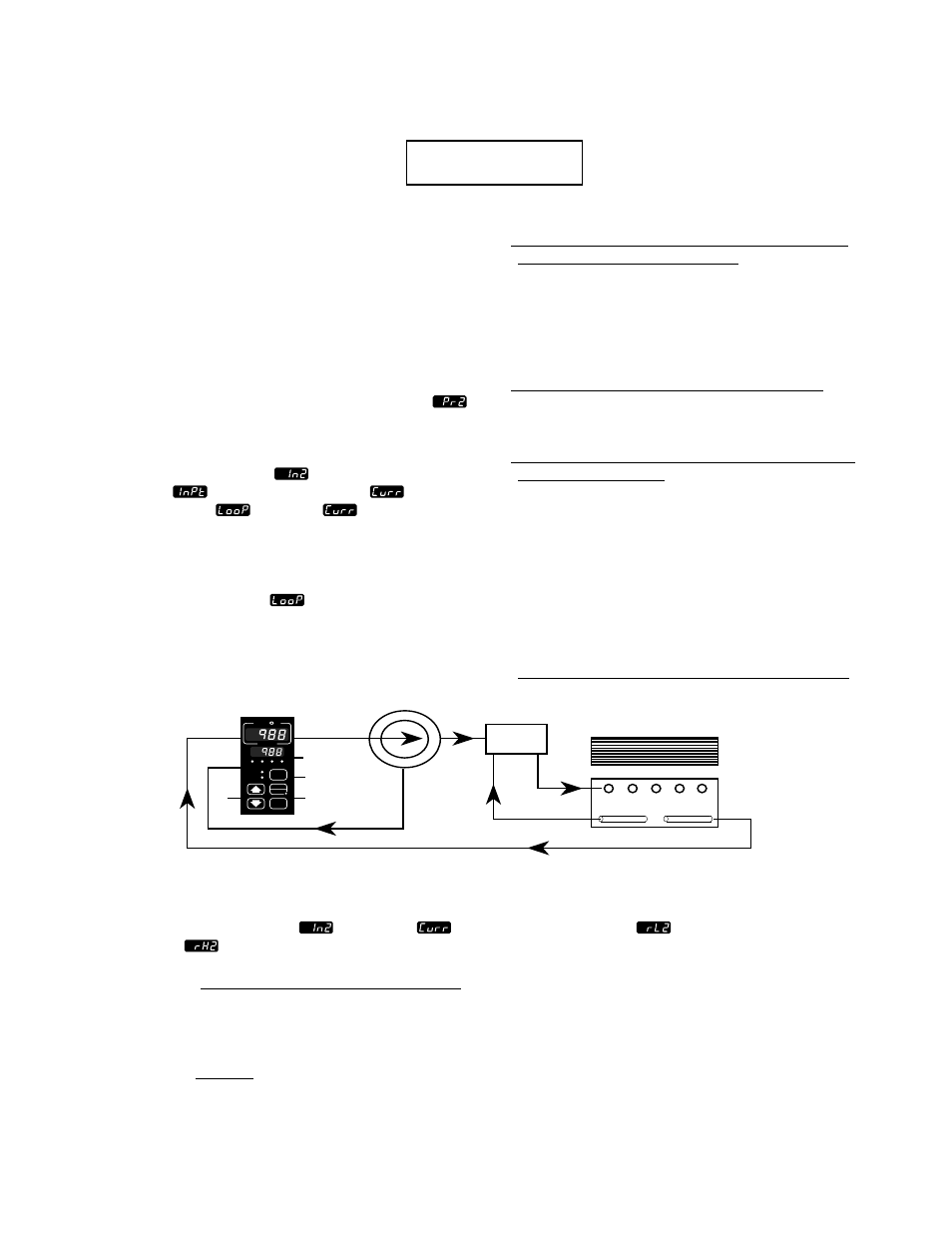

Sample Application

The Series 988 controls the lower platen of a compression molding press that contains five, 10-

ampere heaters. A 50A:50mA current transformer is used to monitor heater current.

Set the input 2 prompt

to current

, the range low 2 prompt

to 0 and the range high 2

prompt

to 50. Find the range high 2 value with the following equation:

range high 2 =

(maximum CT primary current (load current))

x 50mA

(maximum output from CT secondary (input))

The application uses a Watlow current transformer (CT) part# 16-0233, which has a maximum input of 50 amperes, which corre-

sponds to a maximum output of 50mA.

range high 2 =

(50Amps)

x 50mA

Solving for rH2 gives you 50. This is the range high 2 setting.

50mA

Heater Current

Overview

The heater current feature measures and

responds to heater current in a system. This is

an ideal method for detecting heater loss in

multiple heater applications. The current is

measured when output 1 is ON. For instance, if

a system has five, 10-amp heaters, the heater

current input measures 50 amps regardless of

the percent output.

To view the heater current press the DISPLAY

key and advance to the process 2 prompt

.

The upper display indicates the last valid

current reading.

The input 2 prompt

under the Input

menu

can be set to current

or loop

error detect

. Current

allows you to

monitor heater current and set alarm set

points based on high and low heater current

values. Alarms can only be configured as

process alarms (see Alarms, page 5.2). Setting

to loop error detect

enables monitoring

and alarm functions, and also triggers an error

and shuts OFF all outputs if current is present

with output 1 OFF or when no current is

present and output 1 power is more than zero.

There are limits associated with this feature:

•To obtain a reading, the output ON-time must

be a minimum of 0.3 seconds. To calculate

this, multiply the percent output by the cycle

time setting. Example: With 30-percent output

and a 2.0 second cycle time, the on-time would

be: 0.30 x 2.0 = 0.6 seconds. This would yield a

valid reading. If a valid reading is not possible,

the 988 will display the last valid reading.

•It will not function with burst-fire outputs. This

does not necessarily apply to the loop error

detect feature. If enabled, any current detected

with no output triggers an error.

•It will not function when the 988 has a process

output for output 1. A known cycle time is

required to detect the current. There is no cycle

time associated with process outputs.

The maximum signal the input can accept from

the current transformer secondary is 50mA.

So, you must calculate the output range of the

current transformer before wiring the system.

Requirements

Choose the heater current option for input 2.

Output 1 cannot be used as a process output.

Heater current monitors only output 1.

TL

TL

W

WA

PROCESS

L1

L2

L3

L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

10A heaters

input 1

input 2

Compression Molding Press

temperature

sensor

output 1

current

transformer

limit

sensor

limit