Remote set point, General software features – Watlow Optimizing Your Process System with the Series 988 Controller User Manual

Page 31

General Software Features

3.11

Optimizing Your Process System with the WATLOW Series 988

Overview

The remote set point feature allows the 988 to

use a thermocouple, RTD or process signal at

input 2, to establish the set point. This feature

gives the 988 the ability to have its set point

value manipulated by an external source. A

common application would use one ramping

controller with a set-point retransmit output to

ramp multiple 988’s using the remote set point.

Or you could use an analog output from a PLC

to send set point values to a 988.

Requirements

Input 2 must be either a thermocouple or

universal signal conditioner, options 1 or 2.

If the application uses a master controller,

choose one of the retransmit options — M (0-

20, 4-20mA) or N (0-5, 1-5 or 0-10VDC) — for

output 3 of the master.

Match input and output impedances.

Remote Set Point

Sample Application

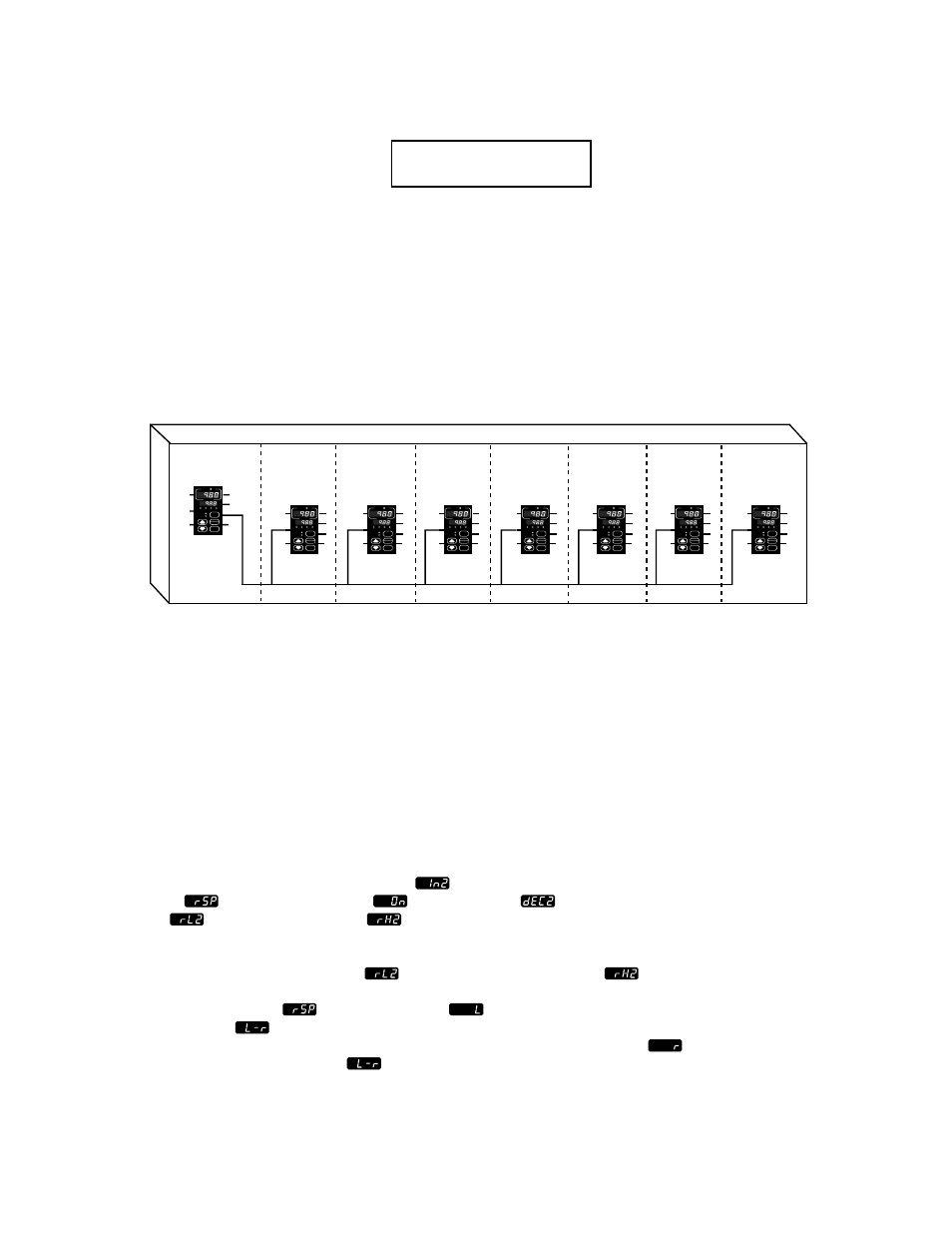

An engineer has a machine with eight independent zones of heat. He wants to

to change set points on all zones without having to adjust each control indi-

vidually. This can be achieved using a 988 with a 0-5VDC retransmit output

as the master controller. The seven remote 988’s will use the 0-5VDC signal

on input 2 as a remote set point. When the set point is changed on the master

controller, the retransmit output changes the set points of the seven remote

controllers. By enabling the ramp to set point feature in the master 988, all

eight zones are ramped up to set point at a user-defined rate on power up.

The retransmit output from the master 988 is set so that 0VDC represents

0

°F and 5VDC represents 800°F. On the remote controllers, set the input 2

DIP switch to the position for the 0-5, 1-5, 0-10VDC process input. In the

Input menu, under the input 2 prompt

, select 0-5. The remote set point

prompt

should be set to ON

and decimal 2

set to 0. The range

low 2

and the range high 2

parameters will establish the scaling for

the remote set point input. Range low 2 should be set to 0 and range high 2

should be set to 800. To operate a specific zone ten degrees hotter than the

others, increase the range low 2

to 10 and the range high 2

to 810.

With remote set point

enabled and local

selected under the local-

remote prompt

in the System menu, the set point is adjusted using the

increment (up-arrow) and decrement (down-arrow) keys. Selecting remote

under the local-remote prompt

, disables the increment and decrement

keys, allowing the set point value to be manipulated via the input 2 signal.

TL

TL

W

WA

PROCESS

L1

L2

L3

L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

TL

TL

W

WA

PROCESS

L1

L2

L3

L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

TL

TL

W

WA

PROCESS

L1

L2

L3

L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

TL

TL

W

WA

PROCESS

L1

L2

L3

L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

TL

TL

W

WA

PROCESS

L1

L2

L3

L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

TL

TL

W

WA

PROCESS

L1

L2

L3

L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

TL

TL

W

WA

PROCESS

L1

L2

L3

L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

TL

TL

W

WA

PROCESS

L1

L2

L3

L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

zone 1

zone 2

zone 3

zone 4

zone 5

zone 6

zone 7

zone 8

Master

Remote

Remote

Remote

Remote

Remote

Remote

Remote

output 3

input 2

input 2

input 2

input 2

input 2

input 2

input 2