Differential, Enhanced software features – Watlow Optimizing Your Process System with the Series 988 Controller User Manual

Page 37

Optimizing Your Process System with the WATLOW Series 988

Enhanced Software Features

4.4

Differential

Overview

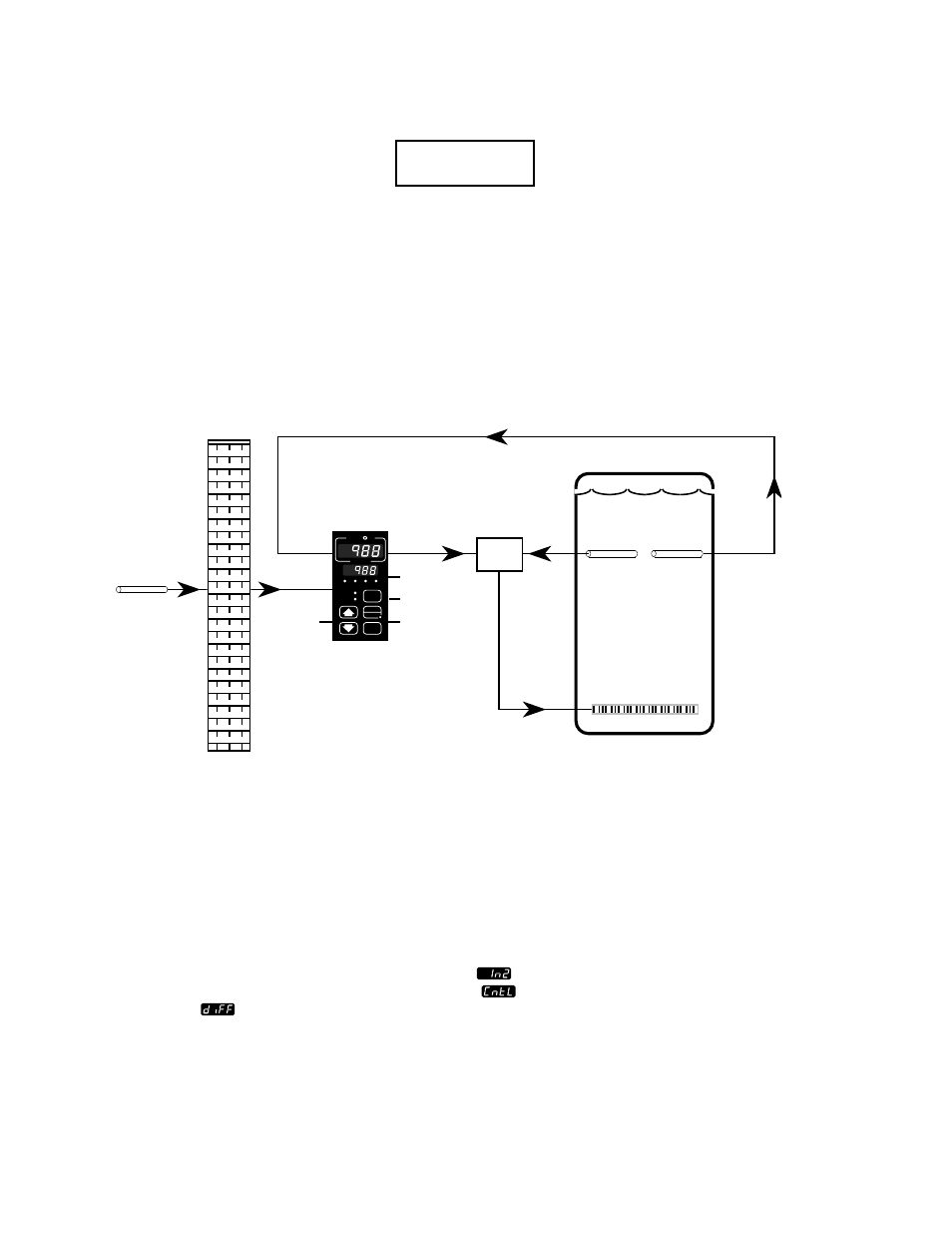

Differential control allows the Series 988 to

control one process at a difference to another

process. Input 2 acts as a remote set point

input. However the displayed set point indi-

cates the desired difference between input 1

and input 2. The set point to which input 1 will

control to is determined by the equation:

internal set point = input 2 + differential set point

The lower display shows the differential set

point, which can be adjusted with the incre-

ment (up-arrow) and decrement (down-arrow)

keys.

Please note that while in the differential control

mode the set point for input 1 cannot be viewed

and must be calculated with the equation.

Requirements

Two inputs and the enhanced software option

are required.

TL

TL

W

WA

PROCESS

L1

L2

L3

L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

limit

sensor

heating element

input 1

input 2

temperature

sensor

outside

temperature

sensor

output 1

limit

Water Boiler

Sample Application

The most common application using differential control is to maintain water

temperature in a boiler at a differential to the outside air temperature. A

thermocouple at input 2 senses the outside air temperature and adjusts the

internal set point to maintain the boiler water temperature 120 degree higher.

Substituting values we have: boiler temperature = outside temperature + 120

°

.

In this application the system uses two, type J thermocouples: one to sense

boiler water temperature (input 1) and one to sense the outside air tempera-

ture (input 2).

To configure the controller, first enable input 2 (set

to J). To enable the

differential control algorithm set the control prompt

in the Global menu

to differential

. Press the DISPLAY key. The lower display will read 0,

indicating no differential between input 1 and input 2. Adjust the set point to

120. The internal set point for input 1 is now equal to the input 2 value plus

120, which will maintain the boiler water temperature 120 degrees higher

than the outside air temperature.