Slidewire feedback, General software features – Watlow Optimizing Your Process System with the Series 988 Controller User Manual

Page 33

General Software Features

3.13

Optimizing Your Process System with the WATLOW Series 988

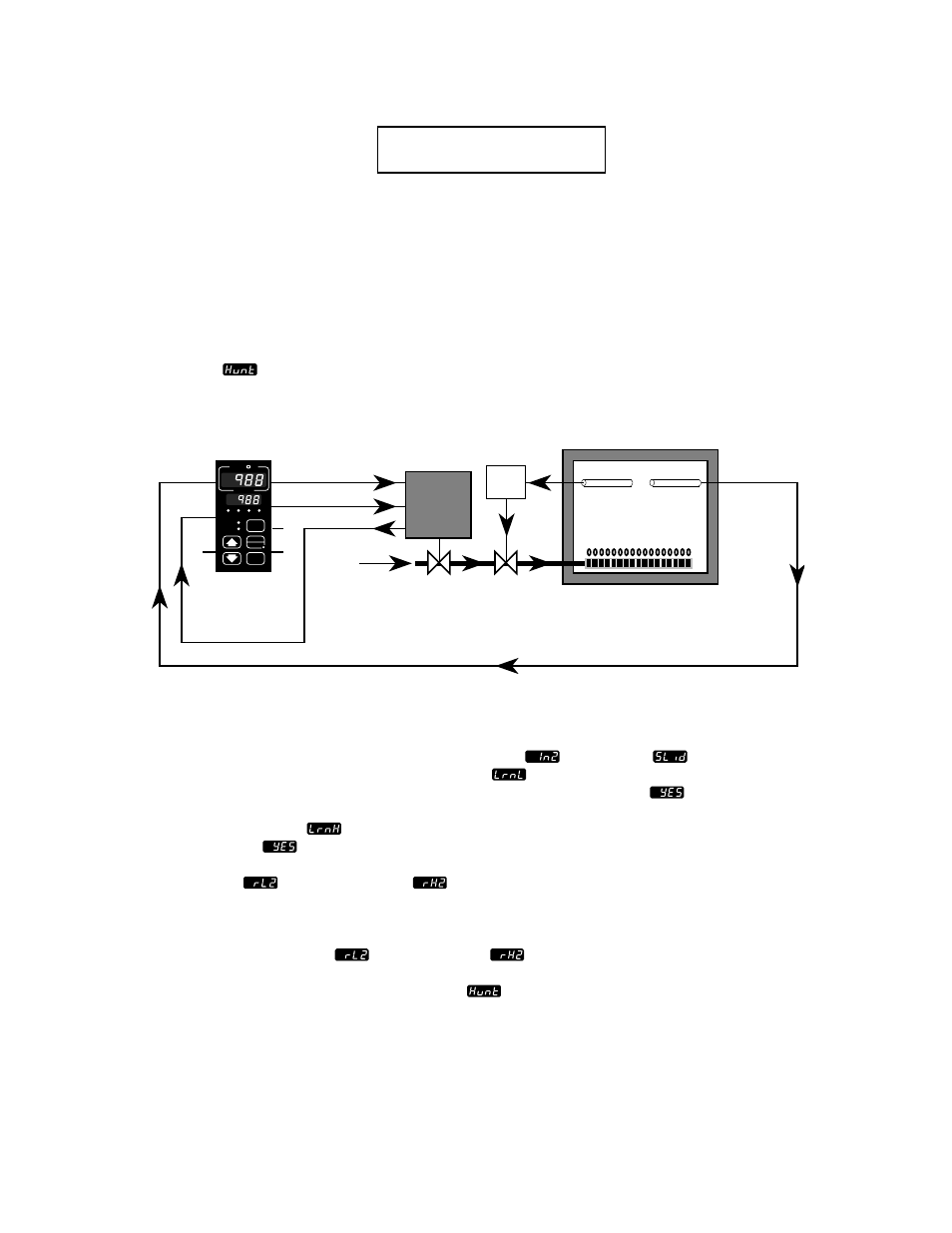

Slidewire Feedback

Overview

The 988 can control the position of a valve with

a slidewire feedback position indicator. The 988

senses the resistance of the slidewire and

compares it to the range low and range high

settings to determine the valve position. The

controller compares this to the percent output

and takes action to match the two by opening

or closing the valve.

Set the hunt

parameter to limit valve

hunting. The value is set for the percent of

output (0.0 to 100.0). When the valve is within

Sample Application

The 988 controls the gas valve for a gas-fired furnace to heat treat large metal

parts. First the 988 must be “married” to the slidewire feedback from the

valve actuator. To do this, first set the input 2 prompt

to slidewire

.

Advance to the learn low resistance value prompt

. Close the valve

manually to the minimum resistance reading from the slidewire. Select

in the upper display and press the MODE key to advance to the learn high

resistance value prompt

. Manually open the valve (maximum slidewire

resistance). Select

in the upper display and press the MODE key. At this

point both the high and low resistance values have been learned and stored in

the range low 2

and range high 2

prompts.

You can also manually set the range low and range high values. From the

slidewire specifications, determine the low and high resistance values and

enter these at the range low

and range high

prompts.

Once the control is operating, adjust the hunt

parameter, to minimize

valve oscillations. The hunt parameter sets up a dead band on both sides of

the current valve position. The desired valve position is then compared to the

actual position. If the difference is greater than the one-half of the hunt value,

the 988 repositions the valve to achieve the temperature set point. Once repo-

sitioning is complete, the dead band is recalculated for the new valve position.

this dead band, a change in output greater

than half the hunt parameter is required to

trigger action. Output 1 responds to “close”

commands and output 2 responds to “open”

commands.

Requirements

A slidewire configuration uses at least two

inputs and two control outputs. Input 2 must

be a slidewire input. Outputs must be compat-

ible with the slidewire valve actuators.

TL

TL

W

WA

PROCESS

L1

L2

L3

L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

temperature

sensor

limit

sensor

input 2

slidewire input

gas

flow

Gas-fired Furnace

limit

input 1

output 1 (close)

output 2 (open)

Valve Actuator

cut-off

valve

gas

valve