Control strategies, Basic control strategies and terms – Watlow Optimizing Your Process System with the Series 988 Controller User Manual

Page 12

Optimizing Your Process System with the WATLOW Series 988

2.2

Basic Control Strategies and Terms

Process Control

Process controls are of two basic types: open

loop and closed-loop. An open-loop control

device has no self-correcting feedback informa-

tion. The closed loop system uses feedback

information from a sensor to adjust the system.

As the process changes, the feedback loop

provides up-to-date status information that the

controlling device uses to make self-correcting

adjustments. The closed-loop control device

provides much better process control.

Control Modes

A variety of control modes offer various degrees

of controllability. The most common modes are

on-off and PID control. The PID control cat-

egory includes varying degrees of complexity

that provide accurate, stable control under a

variety of conditions.

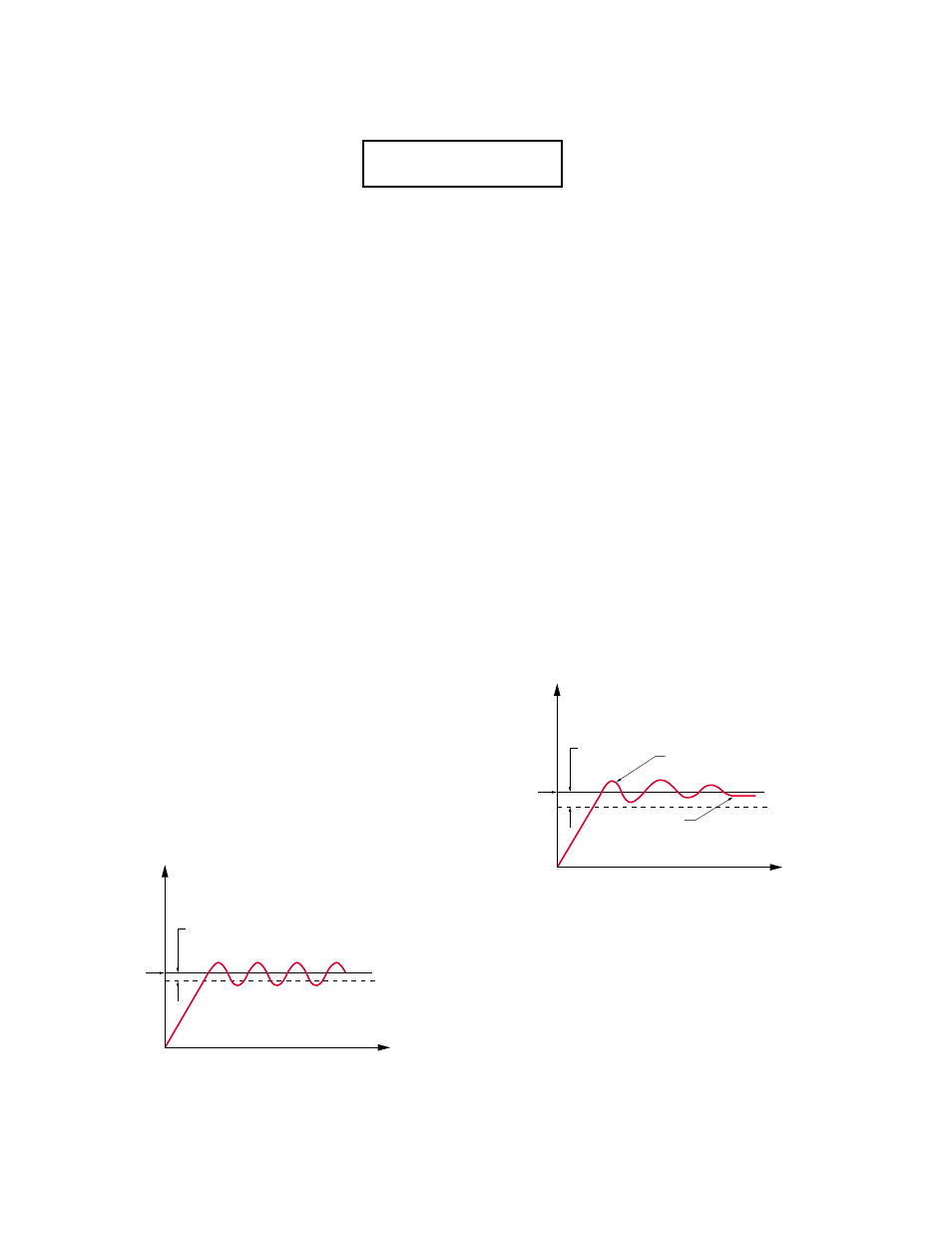

ON/OFF Control

The operation of the ON/OFF control, as the

name implies, turns the output device full ON

or full OFF. Temperature or process sensitivity

(hysterisis) is designed into the control action

between the ON and OFF switching points to

prevent switching the output device ON and

OFF within a span that is too narrow. Switch-

ing repeatedly within such a narrow span will

create a condition of intermittent, rapid switch-

ing, known as output “chattering.” The process

is always controlled “about set point,” dictated

by the switching hysterisis of the ON/OFF

control. This form of control action further

dictates that there will always be a certain

amount of overshoot and undershoot. The

Control Strategies

Proportional

Band

Time Proportioning

Time

Temperature

Set

Point

Droop

Overshoot

Switching

Sensitivity

On - Off

Time

Temperature

Set

Point

degree of overshoot and undershoot will be

dependent on the characteristics of the entire

system.

Time Proportioning

Time-proportioning control provides more

precise control of a process. A time-proportion-

ing control operates in the same way as an ON/

OFF control, when the process is far enough

away from set point to be outside the propor-

tional band. When the process approaches set

point and enters the proportional band, the

output device is switched ON and OFF at the

established cycle time. At the lower limit of the

band, the ON time is considerably greater than

the off time. As the process more closely

approaches set point, the ratio of ON to OFF

time changes: the amount of ON time decreases

as the OFF time increases. This change in

effective power to the load provides a throttling-

back effect, resulting in less overshoot.

The ON and OFF cyclic action continues until a

stable relationship is achieved. At that time,

the system will be stabilized such that the

process is controlled at a point below set point.

The process stabilizes with a resultant droop.

This condition will remain providing there are

no work-load changes in the system.

Integral

If the droop cannot be tolerated, there are ways

to compensate for it. Integral (automatic reset)

is an automatic adjustment to compensate for

Profile developed by proportioning control

Profile produced by ON-OFF control