Dual pid sets, Enhanced software features – Watlow Optimizing Your Process System with the Series 988 Controller User Manual

Page 38

Enhanced Software Features

4.5

Optimizing Your Process System with the WATLOW Series 988

Dual PID sets

Overview:

Standard software units have a single set of

PID parameters. Units with enhanced software

can use two independent sets of heat/cool PID

parameters, PID A

and PID B

. To

enable dual PID, enter the Global menu and set

the algorithm prompt

to dual PID

.

This second set of PID parameters enables the

controller to switch between two sets of PIDs,

to compensate for changes in the system

characteristics. This need can arise from a

variety of circumstances, such as significant

set point changes (controlling at 250, then

controlling at 750), operating a furnace with

half a load versus a full load of steel, changing

the speed of a conveyor through a curing oven

or using different materials in an extruder.

The 988 family can be configured to switch

between PID A and PID B based on a process

value, a set point value or the event input

status. Use the dual PID

prompt in the

Global menu, to select what will cause the

switch: process

; set point

; or none

. If process

is selected at the

prompt, the PID’s will switch based on the

crossover process value. If set point

is

selected at

, the PIDs will switch at the

crossover set point value, PID A used below the

crossover point and PID B above. PID crossover

can also be selected via event input by selecting

at the

or

prompt. PID A is used

when the event input switch is open, PID B

when closed. (Note : One event input is stan-

dard on all units, a second event input is an

option)

Requirements:

The 988 family controller needs the enhanced

software option to use dual PID sets.

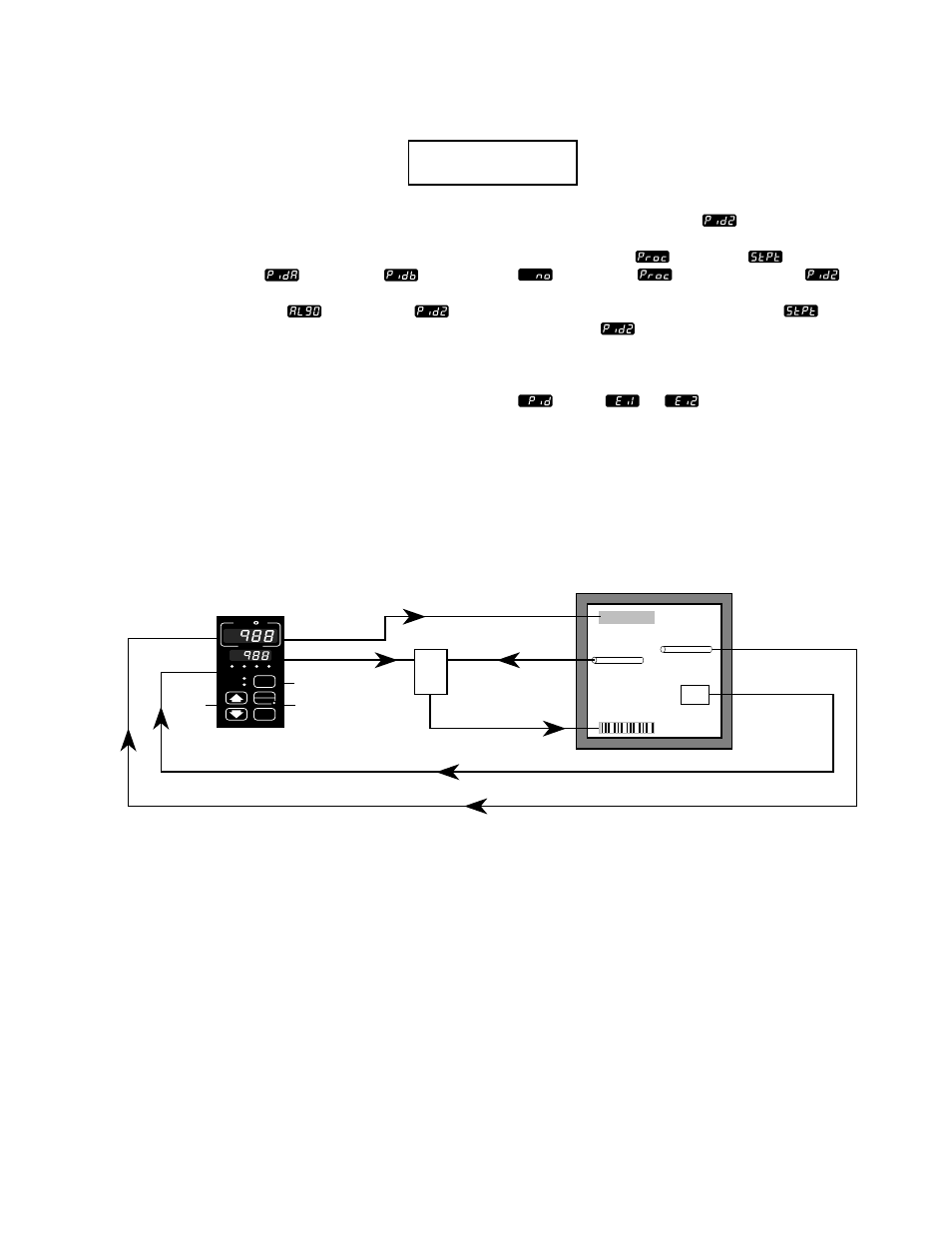

TL

TL

W

WA

PROCESS

L1

L2

L3

L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

pressure

switch

temperature

sensor

heater

chiller

limit

sensor

limit

output 2

output 1

input 2

input 1

Test Chamber

Sample Application:

A test engineer needs to control the temperature in a test chamber that can

be operated at normal atmosphere or under vacuum conditions. If he tunes

the controller for normal atmospheric conditions, when he reaches the portion

of his test that requires a vacuum, he must stop the test and enter new PID

parameters to maintain stable temperatures. The system characteristics are

so very different, that one set of PID’s will not give satisfactory results under

both normal and vacuum conditions.

The 988 solves this problem with the dual PID option. Auto-tuning PID A un-

der normal atmospheric conditions, then auto-tuning PID B under vacuum

conditions, establishes PID values for two sets of system characteristics. A

pressure switch connected to the event input tells the controller when to

switch between PID A and PID B, eliminating the need to change PID values

manually.