Ramp to set point, General software features, Min. ramping – Watlow Optimizing Your Process System with the Series 988 Controller User Manual

Page 30

Optimizing Your Process System with the WATLOW Series 988

General Software Features

3.10

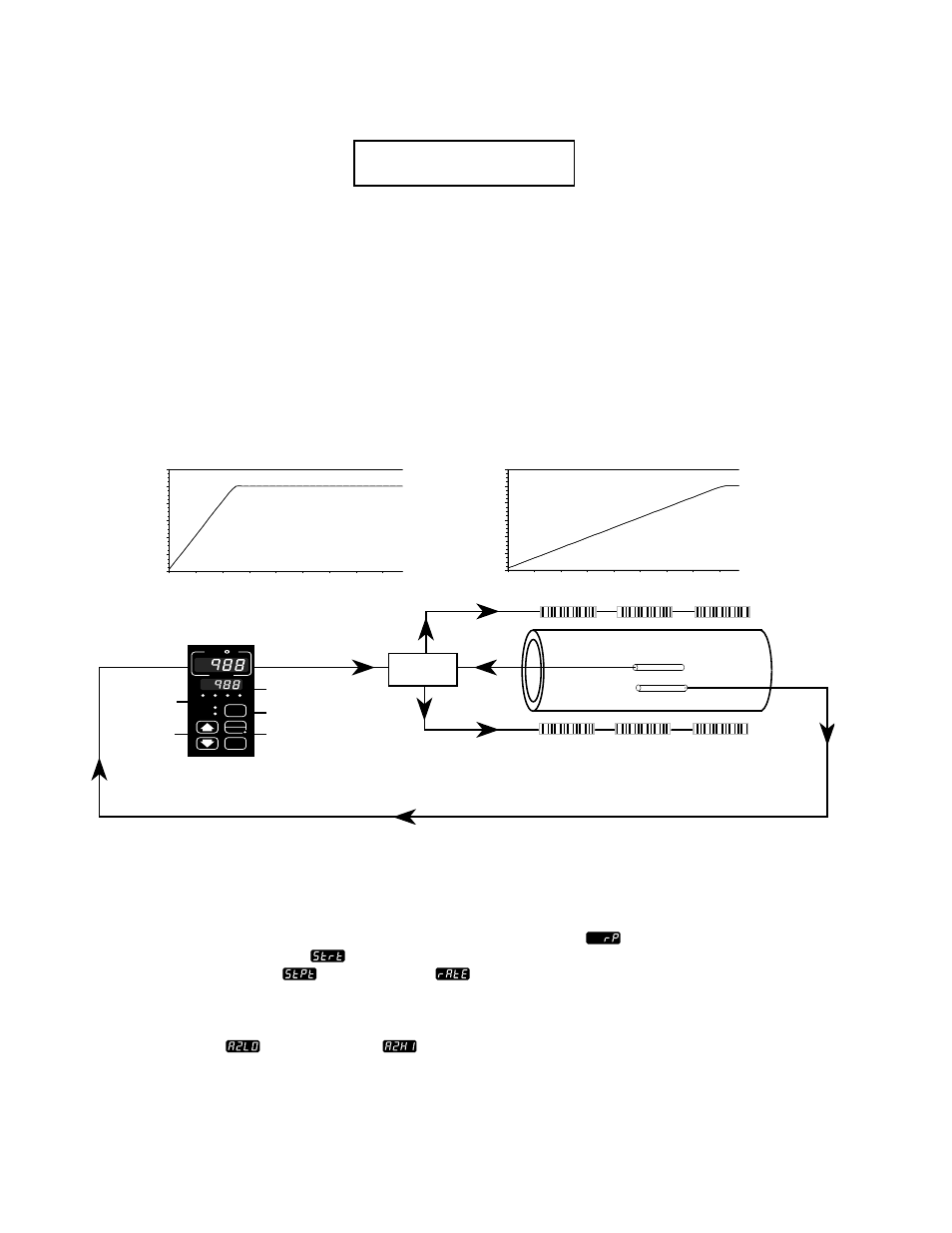

Ramp To Set Point

Overview

Ramp to set point enables the 988 to ramp the

set point at a user defined rate. This allows the

988 to start up a system or change between set

points at a rate that will not stress the product

or system components. The ramp rate is

defined in degrees per minute. Ramp to set

point can be initiated at start up only, or at

start up and also on any set point changes.

When a ramp is initiated, the starting point for

the ramp is the current process value. If the

ramp is initiated on start up, the 988 looks at

°C

0

200

400

600

800

1000

1200

0

2

4

6

8

10

12

14

16

0

200

400

600

800

1000

1200

0

2

4

6

8

10

12

14

16

hours after startup

From start up to set point without ramping

From start up to set point with 1

°

/min. ramping

TL

W

WA

PROCESS

L1

L2

L3

L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

limit

sensor

temperature

sensor

output 1

input 1

limit

heaters

heaters

Sample Application

An engineer needs to control the temperature of a muffle furnace. The furnace set

point must be ramped up at a defined rate to prevent stressing the muffle and

other system components. By enabling the ramp to set point function in the 988,

the engineer can control the rate at which the set point will rise. Ramp to set point

is enabled in the Global menu using the ramping function prompt

. To ramp

on start up only, select start

. To ramp on start up and on any set point

changes, select set point

. The ramp rate

is in degrees per minute.

For further protection of the system, output 2, 3 or 4 can be configured as a rate

alarm, monitoring the rate of increase or decrease in the process variable on input

1. The alarm low

and alarm high

prompts (The "2" in these examples

refer to output 2.) establish the ramp-down and ramp-up rate set points, respec-

tively, in degrees per minute.

°C

hours after startup

the process value upon power up, and uses

that value as the starting point for the ramp. If

a set point change initiates the ramp to set

point function, the 988 looks at the process

value when the change is made and uses that

value as the starting point for the ramp. If the

set point is changed during a ramp, the process

value at the time of the change becomes the

starting point for the new ramp.

Requirements

This feature is standard on all units.