Dead band, General software features – Watlow Optimizing Your Process System with the Series 988 Controller User Manual

Page 25

General Software Features

3.5

Optimizing Your Process System with the WATLOW Series 988

Dead band

Overview

The dead band prompts,

and

,

located in the PID menus, determine the

amount of interaction between heat (reverse

acting) and cool (direct acting) control outputs.

The dead band directly offsets the target set

point of the cool control output.

With a positive dead band, both control out-

puts will never be on at the same time. With

the process in a positive dead band, the output

value is determined by adding the percent heat

output to the percent cool output and only

applying the result to the correct output —

cooling action if the sum is negative and

heating action if it is positive.

If the dead band is set to a negative value, the

heat and cool outputs can both be ON at the

same time.

Requirements

The dead band feature is standard on any

Series 988 controller with two control outputs.

The dead band prompts will appear if the

control outputs are configured for heat/cool or

cool/heat.

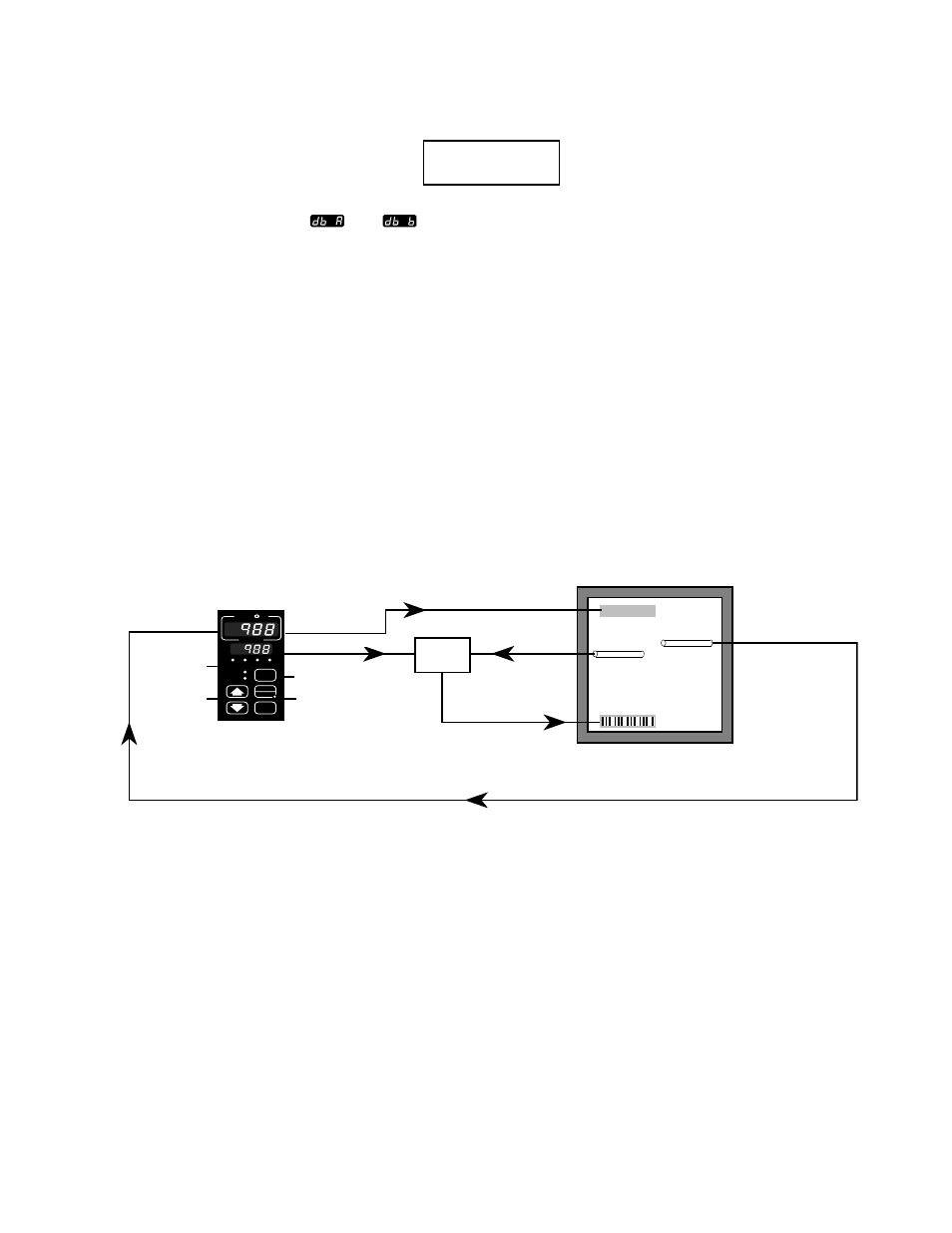

Sample Application

An engineer for an environmental chamber manufacturer, who is design-

ing the heating and cooling system for a new chamber, wants to minimize

the energy costs of operating the chamber. She has chosen the 988 and

will configure the heat and cool outputs with a positive dead band.

When the chamber temperature is near ambient the cooling and heating

systems had a tendency to buck one another, resulting in inefficient use

of energy. The engineer started with a dead band of five degrees, but in

the process of tuning the system for optimal control, the setting was

reduced to two degrees. This made the system more energy efficient and

reduced wear on the refrigeration system.

TL

TL

W

WA

PROCESS

L1

L2

L3

L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

input 1

output 2

output 1

limit

limit

sensor

Environmental Chamber

heater

chiller

temperature sensor