Auto/manual, Standard features – Watlow Optimizing Your Process System with the Series 988 Controller User Manual

Page 44

Optimizing Your Process System with the WATLOW Series 988

Standard Features

5.4

TL

TL

W

WA

PROCESS

L1

L2

L3

L4

DEV

% OUT

DISPLAY

SERIES 988

MODE

AUTO

MAN

Auto/Manual

Overview:

When it operates automatically the controller

uses an input signal (from a thermocouple,

RTD, transmitter, etc.) to determine how best

to adjust the output power level to match a set

point. This constant monitoring of process

variables and the corresponding adjustments

in the output power level is referred to as

closed-loop control. This is the normal mode of

operation for most applications.

Manual operation does not use feedback from

the input signal to determine a power level. The

power level must be adjusted manually by the

operator. The controller may or may not be

monitoring the process variable. This open-loop

control is used for applications in which

closed-loop control is not desired, for instance

as a diagnostic tool or when the controller

detects a sensor break (see Input Errors, page

5.6).

Manual operation provides open-loop control of

the outputs from a range of -100 percent to

+100 percent power (-100 percent for full cool,

+100 percent for full heat). The Series 988

controller allows a negative output value only if

one of the control outputs is configured for

cool.

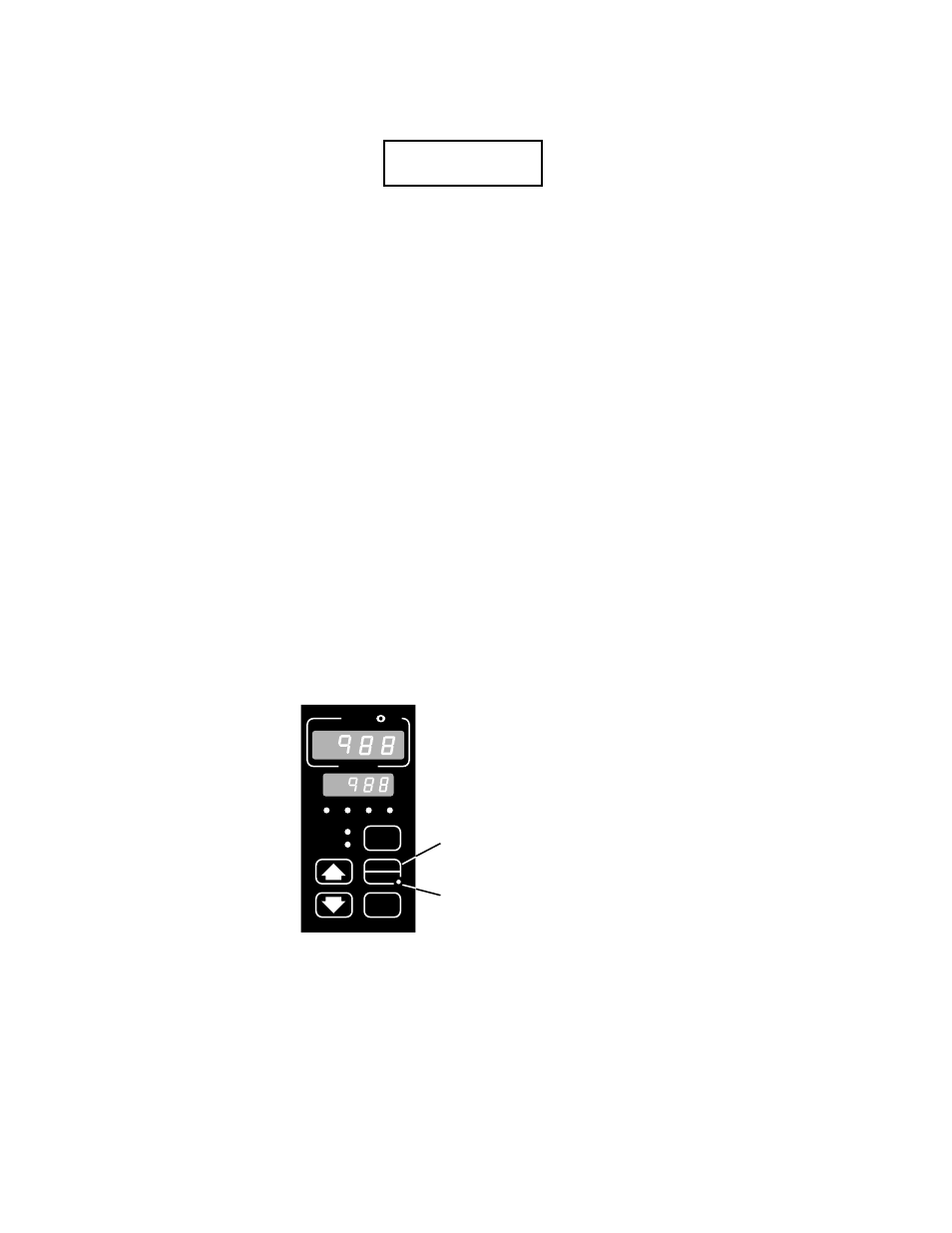

If the LED in the corner of the AUTO/MAN key

is off, the controller is in the automatic mode

and the bottom display is a set point value in

degrees or units. If the LED is on, the controller

is in the manual mode, and the bottom display

indicates the percent power output.

To toggle between auto and manual operation,

press the AUTO/MAN key twice. When you

press the AUTO/MAN key once, the LED in the

lower right hand corner of the AUTO/MAN key,

begins to flash. To complete the change, press

the AUTO/MAN key again while the LED is

flashing. The transition from automatic to

manual is a “bumpless transfer,” the control

will switch to manual mode maintaining the

last power level it used in automatic mode.

Requirements:

Automatic/manual operation is a standard

feature on all units.

Sample Application:

An engineer has a process that needs to be brought on-line at a low power

level, until a predetermined process value is achieved. At this point, the

controller can be allowed to take control of the output power level. Utilizing

the automatic/manual function, the engineer manipulates the power level in

manual mode until it is safe to allow the controller to take control. At that

point, he switches the 988 to the automatic mode, letting the controller

maintain the output power level.

Auto/Manual LED

AUTO/MAN Key