Watlow EZ-ZONE ST User Manual

Page 82

Watlow EZ-ZONE

®

ST

•

80

•

Appendix

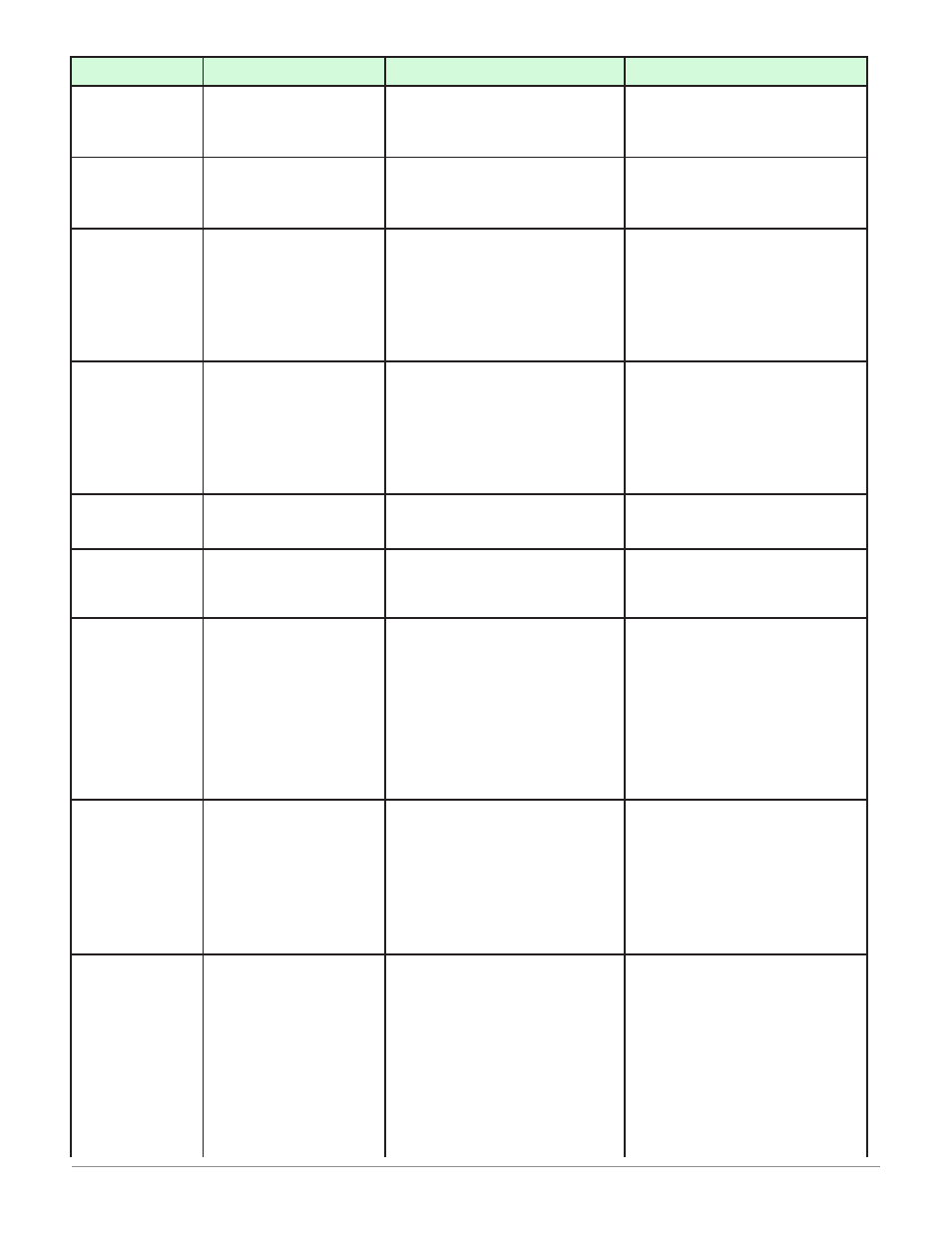

Indication

Description

Possible Cause(s)

Corrective Action

[Li;L1]

Limit Low

[Li;L2]

Sensor input below low limit

set point

• Temperature is less than limit set

point

• Limit outputs latch and require reset

• Incorrect alarm set point

• Check cause of under temperature.

• Clear limit.

• Establish correct limit set point.

[Li;h1]

Limit High

[Li;h2]

Sensor input above high limit

set point

• Temperature is greater than limit set

point

• Limit outputs latch and require reset

• Incorrect alarm set point

• Check cause of over temperature.

• Clear limit.

• Establish correct limit set point.

[LP;o1]

Loop Open Error

Open Loop Detect is active

and the process value did

not deviate by a user-select-

ed value in a user specified

period with PID power at

100%.

• Setting of Open Loop Detect Time

incorrect

• Setting of Open Loop Detect Devia-

tion incorrect

• Thermal loop is open

• Open Loop Detect function not re-

quired but activated

• Set correct Open Loop Detect Time for

application

• Set correct Open Loop Deviation value

for application

• Determine cause of open thermal loop:

misplaced sensors, load failure, loss of

power to load, etc.

• Deactivate Open Loop Detect feature

[LP;r1]

Loop Reversed Error

Open Loop Detect is active

and the process value is

headed in the wrong direc-

tion when the output is

activated based on devia-

tion value and user-selected

value.

• Setting of Open Loop Detect Time

incorrect

• Setting of Open Loop Detect Devia-

tion incorrect

• Output programmed for incorrect

function

• Thermocouple sensor wired in reverse

polarity

• Set correct Open Loop Detect Time for

application

• Set correct Open Loop Deviation value

for application

• Set output function correctly

• Wire thermocouple correctly, (red wire

is negative)

[``rP]

Ramping

Controller is ramping to new

set point

• Ramping feature is activated

• Disable ramping feature if not re-

quired.

[tUNE]

Autotuning

Controller is autotuning the

control loop

• User started the autotune function

• Digital input is set to start autotune

• Wait until autotune completes or dis-

able autotune feature.

• Set digital input to function other

than autotune, if desired.

No heat/cool action

Output does not activate load • Output function is incorrectly set

• Control mode is incorrectly set

• Output is incorrectly wired

• Load, power or fuse is open

• Control set point is incorrect

• Incorrect controller model for applica-

tion

• Set output function correctly.

• Set control mode appropriately (Open

vs Closed Loop).

• Correct output wiring.

• Correct fault in system.

• Set control set point in appropriate

control mode and check source of set

point: remote, idle, profile, closed loop,

open loop.

• Obtain correct controller model for ap-

plication.

No Display

No display indication or LED

illumination

• Power to RUI (Remote User Interface)

is off

• Fuse open

• Breaker tripped

• Safety interlock switch open

• Separate system limit control acti-

vated

• Wiring error

• Incorrect voltage to controller

• Turn on power.

• Replace fuse.

• Reset breaker.

• Close interlock switch.

• Reset limit.

• Correct wiring issue.

• Apply correct voltage, check part num-

ber.

No Serial Communi-

cation

Cannot establish serial com-

munications with the con-

troller

• Address parameter incorrect

• Incorrect protocol selected

• Baud rate incorrect

• Parity incorrect

• Wiring error

• EIA-485 converter issue

• Incorrect computer or PLC communi-

cations port

• Incorrect software setup

• Termination resistor may be required

• Set unique addresses on network.

• Match protocol between devices.

• Match baud rate between devices.

• Match parity between devices.

• Correct wiring issue.

• Check settings or replace converter.

• Set correct communication port.

• Correct software setup to match con-

troller.

• Place 120 Ω resistor across EIA-485

on last controller.