Watlow EZ-ZONE ST User Manual

Page 36

Watlow EZ-ZONE

®

ST

•

34

•

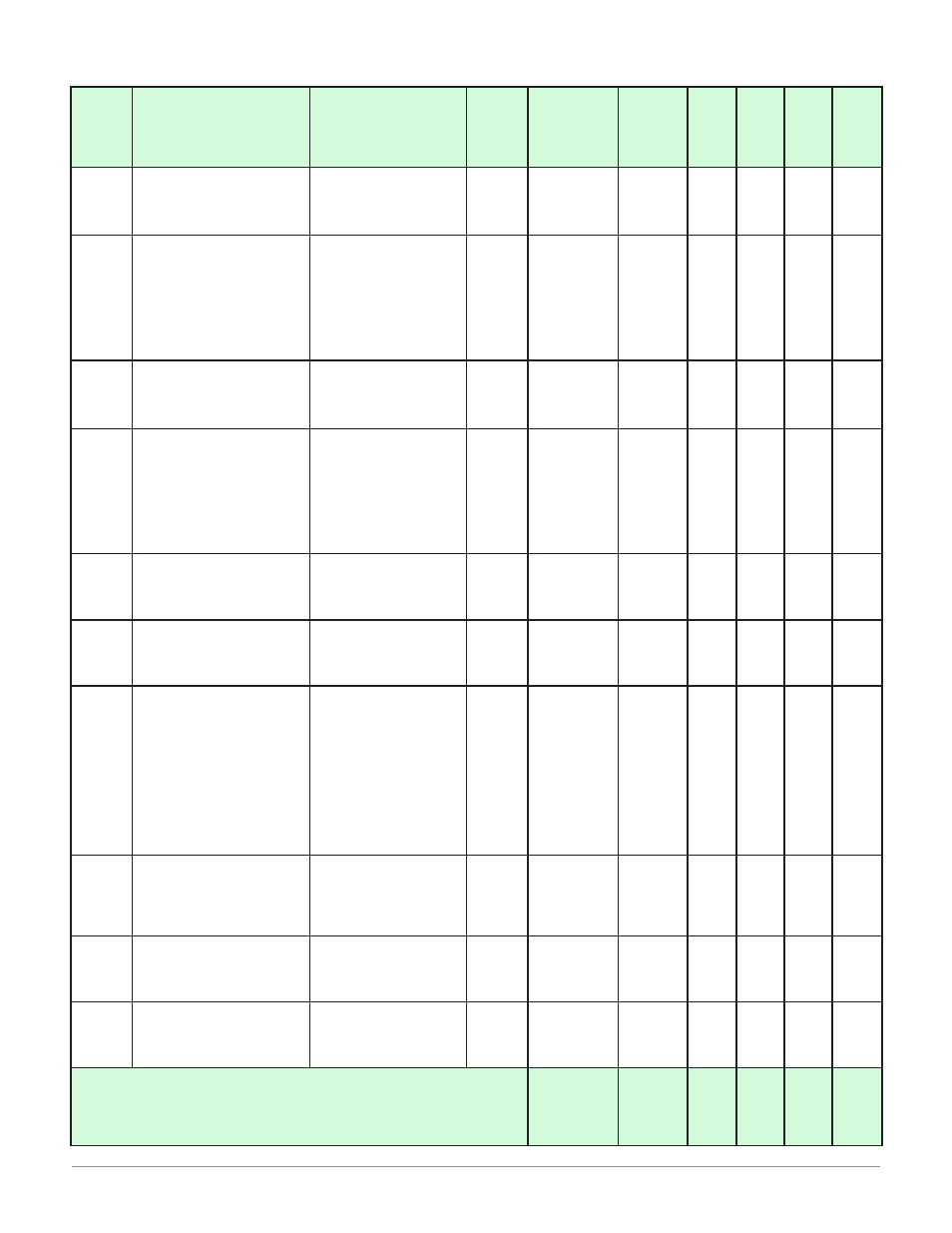

Chapter 3 Operations Page

Operations Page

Display

Parameter Name

Description

Range

Default

Modbus

Relative Ad-

dress

CIP

Class

Instance

Attribute

hex (dec)

Pro DP

Index

Par

ID

RUI/

GTW

Mod-

bus

Data

Type

& Read/

Write

[`h;Pb]

[ h.Pb]

Control Loop (1)

Heat Proportional Band

Set the PID proportional

band for the heat outputs.

0.001 to 9,999.000°F or

units

-1,110.555 to

5,555.000°C

25.0°F

or

units

14.0°C

Instance 1

Map 1 Map 2

232

1760

0x97

(151)

1

6

65

8009 Inst. 1

1896

float

RWES

[`h;hy]

[ h.hy]

Control Loop (1)

Heat Hysteresis

Set the control switching

hysteresis for on-off control.

This determines how far

into the “on” region the pro-

cess value needs to move

before the output turns on.

0.001 to 9,999.000°F or

units

-1,110.555 to

5,555.000°C

3.0°F or

units

2.0°C

Instance 1

Map 1 Map 2

234

1770

0x97

(151)

1

0xB (11)

66

8010 Inst. 1

1898

float

RWES

[`C;Pb]

[ C.Pb]

Control Loop (1)

Cool Proportional Band

Set the PID proportional

band for the cool outputs.

0.001 to 9,999.000°F or

units

-1,110.555 to

5,555.000°C

25.0°F

or

units

14.0°C

Instance 1

Map 1 Map 2

238

1762

0x97

(151)

1

7

67

8012 Inst. 1

1902

float

RWES

[`C;hy]

[ C.hy]

Control Loop (1)

Cool Hysteresis

Set the control switching

hysteresis for on-off control.

This determines how far

into the “on” region the pro-

cess value needs to move

before the output turns on.

0.001 to 9,999.000°F or

units

-1,110.555 to

5,555.000°C

3.0°F or

units

2.0°C

Instance 1

Map 1 Map 2

240

1772

0x97

(151)

1

0xC (12)

68

8013 Inst. 1

1904

float

RWES

[``ti]

[ ti]

Control Loop (1)

Time Integral

Set the PID integral for the

outputs.

0 to 9,999 seconds per

repeat

180.0

seconds

per re-

peat

Instance 1

Map 1 Map 2

226

1764

0x97

(151)

1

8

69

8006 Inst. 1

1890

float

RWES

[``td]

[ td]

Control Loop (1)

Time Derivative

Set the PID derivative time

for the outputs.

0 to 9,999 seconds

0.0

seconds

Instance 1

Map 1 Map 2

228

1766

0x97

(151)

1

9

70

8007 Inst. 1

1892

float

RWES

[``dB]

[ db]

Control Loop (1)

Dead Band

Set the offset to the propor-

tional band. With a nega-

tive value, both heating and

cooling outputs are active

when the process value is

near the set point. A posi-

tive value keeps heating

and cooling outputs from

fighting each other.

-1,000.0 to 1,000.0°F or

units

-556 to 556°C

0.0

Instance 1

Map 1 Map 2

230

1768

0x97

(151)

1

0xA (10)

71

8008 Inst. 1

1894

float

RWES

[`o;SP]

[ o.SP]

Control Loop (1)

Open Loop Set Point

Set a fixed level of output

power when in manual

(open-loop) mode.

-100 to 100% (heat and

cool)

0 to 100% (heat only)

-100 to 0% (cool only)

0.0

Instance 1

Map 1 Map 2

23

1892

0x6B

(107)

1

2

51

7002 Inst. 1

- - - -

float

RWES

No Dis-

play

Control Loop (1)

Loop Error

Open Loop detect deviation

has been exceeded.

None (61)

Open Loop (1274)

Reversed Sensor (1275)

- - - -

Instance 1

Map 1 Map 2

- - - - 1798

0x6C (108)

1

0x30 (48)

- - - -

8048 Inst. 1

- - - -

uint

R

No Dis-

play

Control Loop (1)

Clear Loop Error

Current state of limit out-

put.

Clear (129)

Ignore (204)

- - - -

Instance 1

Map 1 Map 2

- - - - 1800

0x6C (108)

1

0x31 (49)

- - - -

8049 Inst. 1

- - - -

uint

W

Note:

Some values will be rounded off to fit in the four-character display . Full values can be

read with other interfaces .

If there is only one instance of a menu, no submenus will appear .

R: Read

W: Write

E: EE-

PROM

S: User

Set