Control methods, Set point low limit and high limit, Scale high and scale low – Watlow EZ-ZONE ST User Manual

Page 70: Range high and range low, Output configuration, Auto (closed loop) and manual (open loop) control, Range high and range low control methods

Watlow EZ-ZONE

®

ST

•

68

•

Chapter 7 Features

Select the sensor type with Sensor Type [`Sen]

(Setup Page, Analog Input Menu).

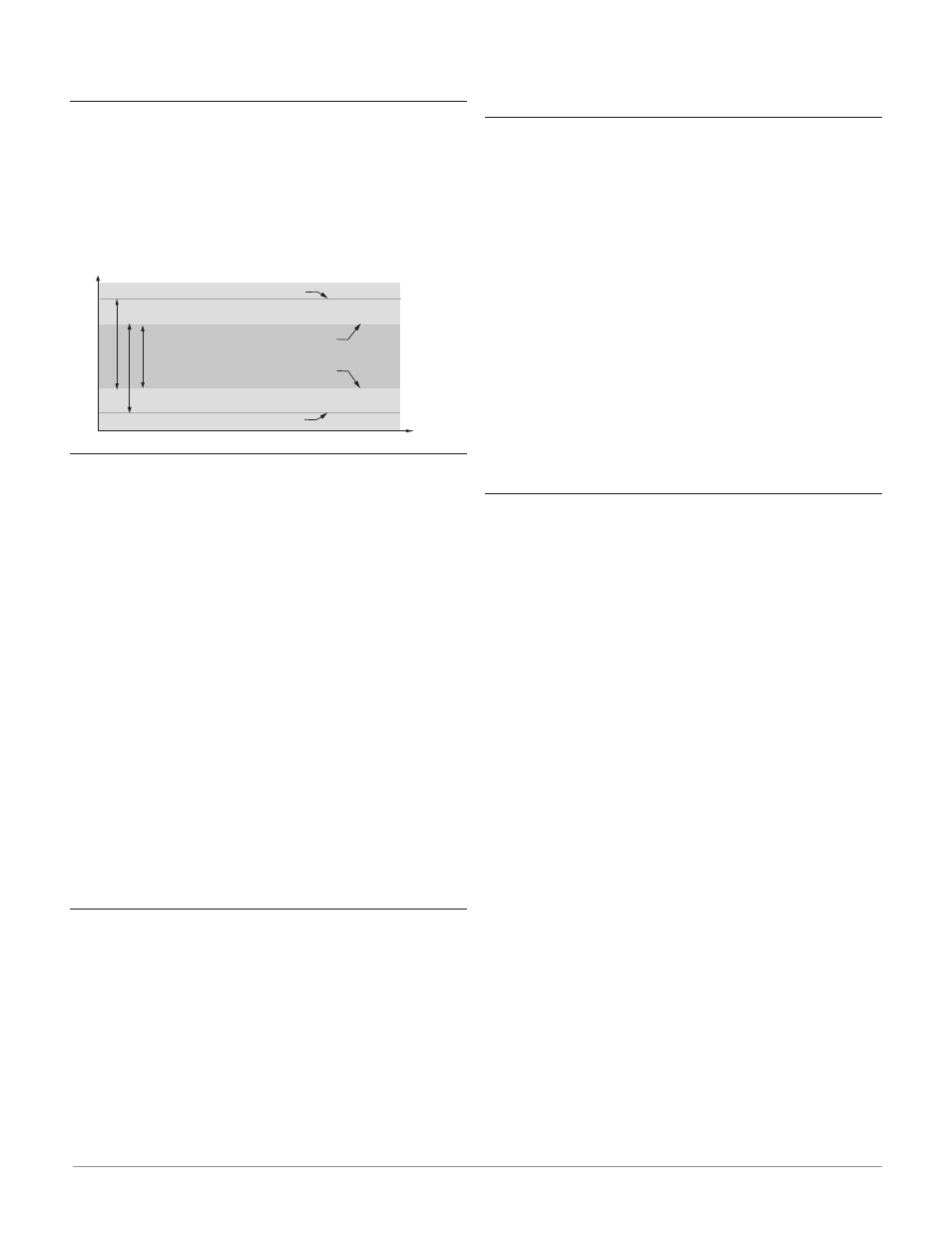

Set Point Low Limit and High Limit

The controller constrains the set point to a value be-

tween a set point low limit and a set point high limit.

Set the set point limits with Low Set Point [`L;SP]

and High Set Point [`h;SP] (Setup Page, Loop Menu).

There are two sets of set point low and high limits:

one for a closed-loop set point, another for an open-

loop set point.

Set Point Range (must be between Range High and Range Low)

Low Limit of selected functional range

High Limit of selected functional range

Gas Pressure

Range Low and Range High

Range High Range (between High Limit of Sensor and Range Low)

Range Low Range (between Low Limit of Sensor and Range High)

Set Point Low

Set Point High

Scale High and Scale Low

When an analog input is selected as process voltage

or process current input, you must choose the value

of voltage or current to be the low and high ends. For

example, when using a 4 to 20 mA input, the scale low

value would be 4.00 mA and the scale high value would

be 20.00 mA. Commonly used scale ranges are: 0 to 20

mA, 4 to 20 mA, 0 to 5V, 1 to 5V and 0 to 10V.

You can create a scale range representing other

units for special applications. You can reverse scales

from high values to low values for analog input sig-

nals that have a reversed action. For example, if 50 psi

causes a 4 mA signal and 10 psi causes a 20 mA signal.

Scale low and high low values do not have to match

the bounds of the measurement range. These along

with range low and high provide for process scaling and

can include values not measureable by the controller.

Regardless of scaling values, the measured value will

be constrained by the electrical measurements of the

hardware.

Select the low and high values with Scale Low

[`S;Lo]

and Scale High [`S;hi]. Select the displayed

range with Range Low [`r;Lo] and Range High

[`r;hi]

(Setup Page, Analog Input Menu).

Range High and Range Low

With a process input, you must choose a value to rep-

resent the low and high ends of the current or voltage

range. Choosing these values allows the controller’s

display to be scaled into the actual working units of

measurement. For example, the analog input from a

humidity transmitter could represent 0 to 100 percent

relative humidity as a process signal of 4 to 20 mA.

Low scale would be set to 0 to represent 4 mA and

high scale set to 100 to represent 20 mA. The indica-

tion on the display would then represent percent hu-

midity and range from 0 to 100 percent with an input

of 4 to 20 mA.

Select the low and high values with Range Low

[`r;Lo]

and Range High [`r;hi] (Setup Page, Analog

Input Menu).

Control Methods

Output Configuration

Each controller output (1, 2 and 3) can be configured

as a heat output, a cool output, an alarm output or de-

activated. No dependency limitations have been placed

on the available combinations. The outputs can be

configured in any combination. For instance, all three

could be set to cool.

Heat and cool outputs use the set point and Opera-

tions parameters to determine the output value. All

heat and cool outputs use the same set point value.

Heat and cool each have their own set of control pa-

rameters. All heat outputs use the same set of heat

control parameters and all cool outputs use the same

set of cool output parameters.

Each alarm output has its own set of configuration

parameters and set points, allowing independent op-

eration.

Auto (closed loop) and Manual (open loop) Control

The controller has two basic modes of operation, auto

mode and manual mode. Auto mode allows the control-

ler to decide whether to perform closed-loop control or

to follow the settings of Input Error Failure [FAiL]

(Setup Page, Loop Menu). The manual mode only al-

lows open-loop control. The EZ-ZONE ST controller

is normally used in the auto mode. The manual mode

is usually only used for specialty applications or for

troubleshooting.

Manual mode is open-loop control that allows the

user to directly set the power level to the controller’s

output load. No adjustments of the output power level

occur based on temperature or set point in this mode.

In auto mode, the controller monitors the input to

determine if closed-loop control is possible. The con-

troller checks to make certain a functioning sensor is

providing a valid input signal. If a valid input signal is

present, the controller will perform closed-loop control.

Closed-loop control uses a process sensor to determine

the difference between the process value and the set

point. Then the controller applies power to a control

output load to reduce that difference.

If a valid input signal is not present, the control-

ler will indicate an input error message in the upper

display and [Attn] in the lower display and respond

to the failure according to the setting of Input Error

Failure [FAiL]. You can configure the controller to

perform a “bumpless” transfer [bPLS], switch power to

output a preset fixed level [MAn], or turn the output

power off.

Bumpless transfer will allow the controller to

transfer to the manual mode using the last power

value calculated in the auto mode if the process had

stabilized at a ±5 percent output power level for the

time interval of Time Integral (Operations Page, Loop)