Saving and restoring user settings, Tuning the pid parameters, Manual tuning – Watlow EZ-ZONE ST User Manual

Page 67

Watlow EZ-ZONE

®

ST

•

65

•

Chapter 7 Features

Saving and Restoring User Settings

Recording setup and operations parameter settings

for future reference is very important. If you uninten-

tionally change these, you will need to program the

correct settings back into the controller to return the

equipment to operational condition.

After you program the controller and verify proper

operation, use User Save Set [USr;S] (Setup Page,

Global Menu) to save the settings into either of two

files in a special section of memory. If the settings in

the controller are altered and you want to return the

controller to the saved values, use User Restore Set

[USr;r]

(Setup Page, Global Menu) to recall one of the

saved settings.

A digital input or the RUI Function Key can also

be configured to restore parameters.

Note:

Only perform the above procedure when you are sure that all the

correct settings are programmed into the controller . Saving he set-

tings overwrites any previously saved collection of settings . Be sure

to document all the controller settings .

Tuning the PID Parameters

Autotuning

When an autotune is performed on the EZ-ZONE

®

ST,

the set point is used to calculate the tuning set point.

For example, if the active set point is 200° and

Autotune Set Point [A;tSP] (Operations Page, Loop

Menu) is set to 90 percent, the autotune function

utilizes 180° for tuning. This is also how autotuning

works in previous Watlow controllers. In addition,

changing the active set point in previous controllers

causes the autotune function to restart; where with

the EZ-ZONE ST changing the set point after an au-

totune has been started has no affect.

A new feature in EZ-ZONE ST products will allow

set point changes while the control is autotuning, this

includes while running a profile or ramping. When

the auto tune is initially started it will use the cur-

rent set point and will disregard all set point changes

until the tuning process is complete. Once complete,

the controller will then use the new set point.

This is why it is a good idea to enter the active set

point before initiating an autotune.

Autotuning calculates the optimum heating and/or

cooling PID parameter settings based on the system's

response. Autotuning can be enabled whether or not

TUNE-TUNE+

®

is enabled. The PID settings gener-

ated by the autotune will be used until the autotune

feature is rerun, the PID values are manually adjust-

ed or TRU-TUNE+

®

is enabled.

To initiate an autotune, set Autotune Request

[`AUt]

(Operations Page, Loop Menu) to [`YES].

You should not autotune while a profile is running. If

the autotune cannot be completed in 60 minutes, the

autotune will time-out and the original settings will

take effect.

The lower display will flash between [tUnE] and

the set point while the autotun-

ing is underway. The temperature must cross the Au-

totune Set Point five times to complete the autotuning

process. Once complete, the controller controls at the

normal set point, using the new parameters.

Select a set point for the tune with Autotune Set

Point. The Autotune Set Point is expressed as a per-

cent of the Closed Loop Set Point.

If you need to adjust the tuning procedure's ag-

gressiveness, use Autotune Aggressiveness [T;Agr]

(Setup Page, Loop Menu). Select under damped [Un-

dr]

to bring the process value to the set point quickly.

Select over damped [ouer] to bring the process value

to the set point with minimal overshoot. Select criti-

cal damped [Crit] to balance a rapid response with

minimal overshoot.

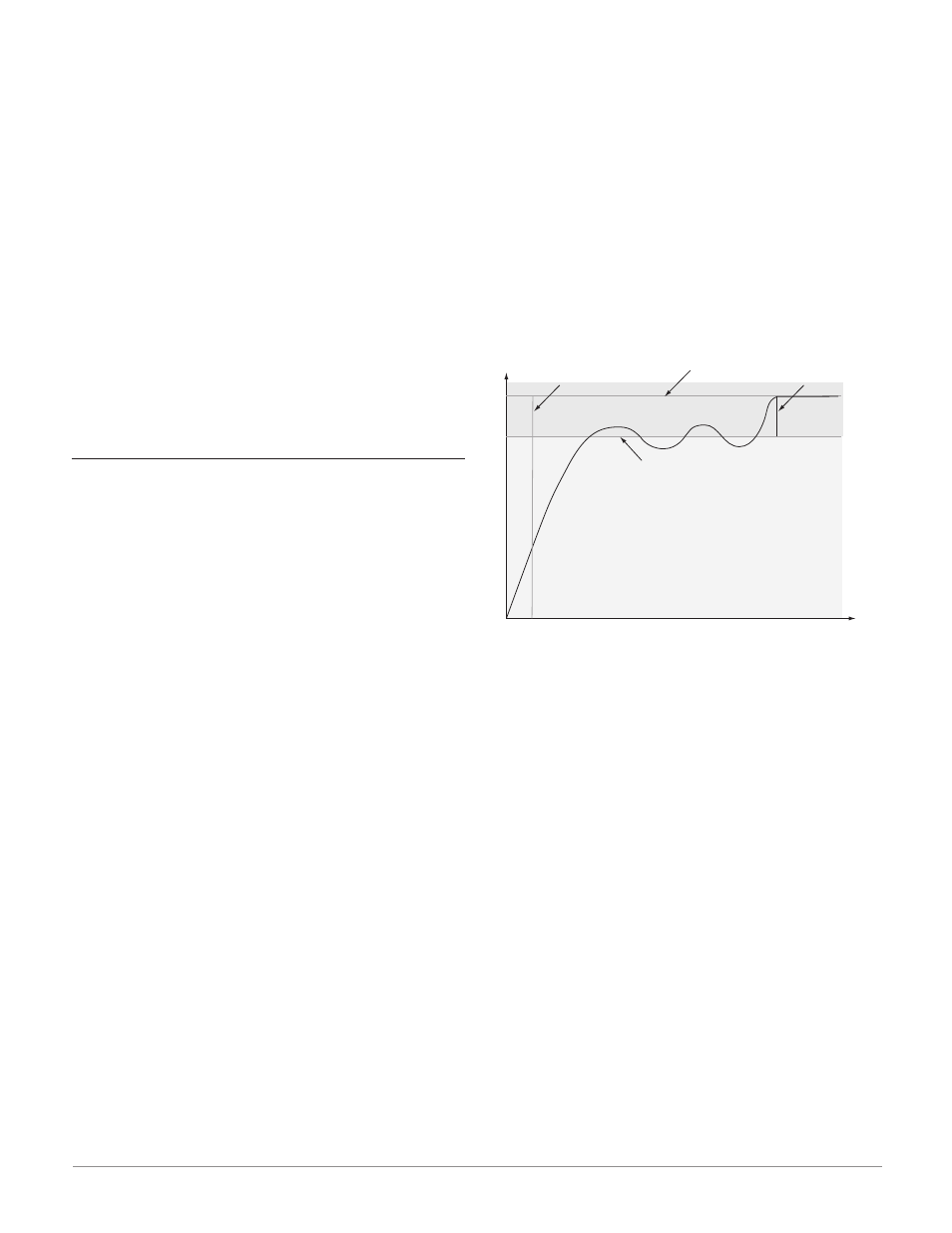

Time

Temperature

Autotune begins

Process Set Point

Autotune Set Point

(90 percent of Process Set Point)

Autotune complete

Manual Tuning

In some applications, the autotune process may not

provide PID parameters for the process characteris-

tics you desire. If that is the case, you may want to

tune the controller manually.

1. Apply power to the controller and establish a set

point typically used in your process.

2. Go to the Operations Page, Loop Menu, and set

Heat Proportional Band [`h;Pb] and/or Cool Pro-

portional Band [`C;Pb] to 5. Set Time Integral

[``ti]

to 0. Set Time Derivative [``td] to 0.

3. When the system stabilizes, watch the process

value. If it fluctuates, increase the Heat Propor-

tional Band or Cool Proportional Band value in 3

to 5° increments until it stabilizes, allowing time

for the system to settle between adjustments.

4. When the process has stabilized, watch Heat

Power [`h;Pr] or Cool Power [`C;Pr] (Operations

Page, Monitor Menu). It should be stable ±2%. At

this point, the process temperature should also be

stable, but it will have stabilized before reaching

the set point. The difference between the set point

and actual process value can be eliminated with

Integral.

5. Start with an Integral value of 6,000 and allow

10 minutes for the process temperature to reach