Alarms, Process and deviation alarms, Alarm set points – Watlow EZ-ZONE ST User Manual

Page 74: Alarm hysteresis, Alarm latching, Heating system with ramping, Alarm set points and hysteresis, Alarm response with hysteresis

Watlow EZ-ZONE

®

ST

•

72

•

Chapter 7 Features

Set Point

Time

Temperature

Heating System with Ramping

Temperature ramps to Set Point at a set rate

degrees

per minute

Alarms

Alarms are activated when the output level, process

value or temperature leaves a defined range. A user

can configure how and when an alarm is triggered,

what action it takes and whether it turns off automat-

ically when the alarm condition is over.

Configure alarm outputs in the Setup Page before

setting alarm set points.

Alarms do not have to be assigned to an output.

Alarms can be monitored and controlled through the

front panel or by using software.

Process and Deviation Alarms

A process alarm uses one or two absolute set points to

define an alarm condition.

A deviation alarm uses one or two set points that

are defined relative to the control set point. High and

low alarm set points are calculated by adding or sub-

tracting offset values from the control set point. If the

set point changes, the window defined by the alarm

set points automatically moves with it.

Select the alarm type with Type [`A;ty] (Setup

Page, Alarm Menu).

Alarm Set Points

The alarm high set point defines the process value

or temperature that will trigger a high side alarm. It

must be higher than the alarm low set point and lower

than the high limit of the sensor range.

The alarm low set point defines the temperature

that will trigger a low side alarm. It must be lower

than the alarm high set point and higher than the low

limit of the sensor range.

View or change alarm set points with Low Set

Point [`A;Lo] and High Set Point [`A;hi] (Operations

Page, Alarm Menu).

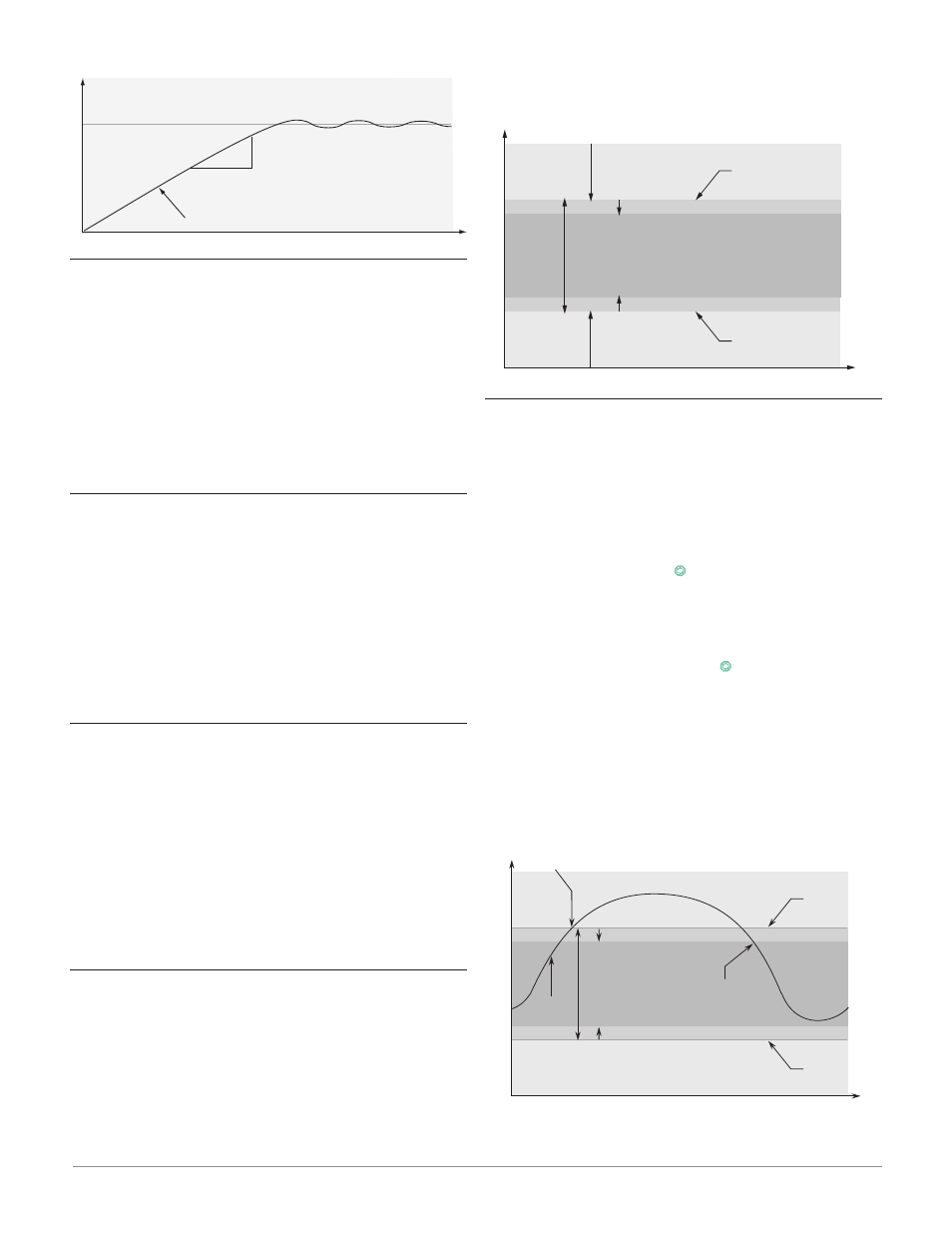

Alarm Hysteresis

An alarm state is triggered when the process value

reaches the alarm high or alarm low set point. Alarm

hysteresis defines how far the process must return

into the normal operating range before the alarm can

be cleared.

Alarm hysteresis is a zone inside each alarm set

point. This zone is defined by adding the hysteresis

value to the alarm low set point or subtracting the

hysteresis value from the alarm high set point.

View or change alarm hysteresis with Hysteresis

[`A;hy]

(Setup Page, Alarm Menu).

Normal Operating Range

Low Side Alarm Range

High Side Alarm Range

Alarm High Set Point

Alarm Low Set Point

Time

Temperature

Alarm Set Points and Hysteresis

Alarm Hysteresis

Alarm Hysteresis

Alarm Latching

A latched alarm will remain active after the alarm

condition has passed. It can only be deactivated by the

user.

An active message, such as an alarm message, will

cause the display to toggle between the normal set-

tings and the active message in the upper display and

[Attn]

in the lower display.

Push the Advance Key

‰

to display [ignr] in the

upper display and the message source in the lower

display.

Use the Up ¿ and Down ¯ keys to scroll through

possible responses, such as Clear [`CLr] or Silence

[`SiL]

. Then push the Advance

‰

or Infinity ˆ key to

execute the action.

See the Keys and Displays chapter and the Home

Page chapter for more details.

An alarm that is not latched (self-clearing) will de-

activate automatically when the alarm condition has

passed.

Turn alarm latching on or off with Latching

[`A;LA]

(Setup Page, Alarm Menu).

Normal Operating Range

Alarm High

Set Point

Time

Temperature

Alarm Low

Set Point

Alarm Response with Hysteresis

The alarm state continues until the

temperature drops to the Alarm High

Set Point minus the hysteresis. A

latching alarm could be turned off by

the operator at this point. A non-

latching alarm would turn off

automatically.

The alarm state begins when the temperature

reaches the Alarm High Set Point

Process

Temperature

Alarm Hysteresis