IAI America ACON-CY User Manual

Page 108

96

7. T

roubleshooting

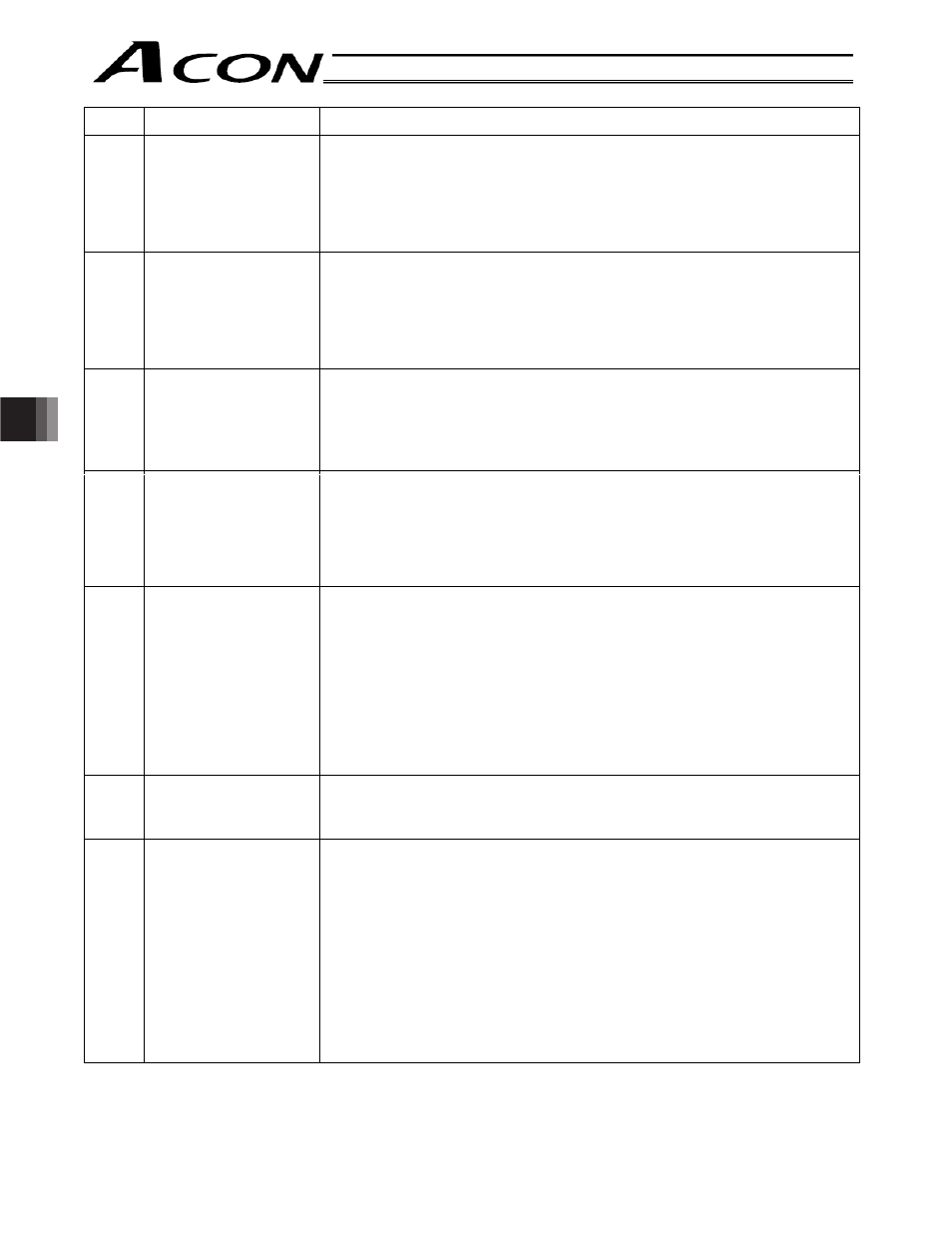

Code

Error

Cause/action

0CC

Excessive control

power-supply voltage

This alarm indicates that the voltage of the 24-V input power supply is

excessive (24 V + 20%: 28.8 V or above).

Cause: [1] The voltage of the 24-V input power supply is high.

[2] Faulty part in the controller

Action: Check the input power-supply voltage.

If the voltage is normal, contact IAI.

0CE

Low control

power-supply voltage

This alarm indicates that the voltage of the 24-V input power supply is low (24

V – 20%: 19.2 V or below).

Cause: [1] The voltage of the 24-V input power supply is low.

[2] Faulty part in the controller

Action: Check the input power-supply voltage.

If the voltage is normal, contact IAI.

0D8

Deviation overflow

The position deviation counter has overflowed.

0D2

Cause: The speed dropped during movement due to the effect of an external

force, etc.

Action: Check the load conditions—such as whether the load is contacting a

surrounding object or the brake is disengaged—and then correct the

abnormality, if any

0D9

Software stroke limit

overtravel error

Cause: [1] The actuator installed vertically overshot and exceeded a

software stroke limit due to a large load or high deceleration

setting when the target position was set to a point near the

software stroke limit.

[2] The actuator was moved to outside the software stroke limits

with the servo turned off, and then the servo was turned on.

Action: [1] Set the deceleration curve properly so that the actuator will not

overshoot when stopping.

[2] Return the actuator to inside the software stroke limits, and then

turn on the servo.

0DC

Out of push & hold

operation range error

This error occurs when the actuator was pushed back to the target position

due to an excessive push force after completion of push & hold operation.

Review the entire system.

0ED

Absolute encoder error

(1)

Cause: [1] When the power was reconnected following the completion of an

absolute reset, the current position changed due to an external

factor, etc., while the ABS unit was communicating.

[2] When an absolute reset was performed, the current position

changed due to an external factor, etc., while the controller was

communicating with the simple absolute unit.

Action: [1] Detail code = H’0001

Turn on the power and then turn it back on in a condition where

the actuator does not receive vibration, etc.

[2] Detail code = H’0002

Perform an origin return operation again in a condition where the

actuator does not receive vibration, etc.

Cause: This error occurs when overvoltage of motor power has been

detected (38V or more)

Action: Check the motor power input voltage (MPI terminal).

In case there is no fault found in voltage, malfunction of controller

can be considered. Please contact us.

Excessive motor

power-supply voltage