Warning, Arm 1 arm 2 – IAI America IX-NNN3515 User Manual

Page 43

35

6. Inspection/Maintenance

6.

Press the emergency-stop switch.

7.

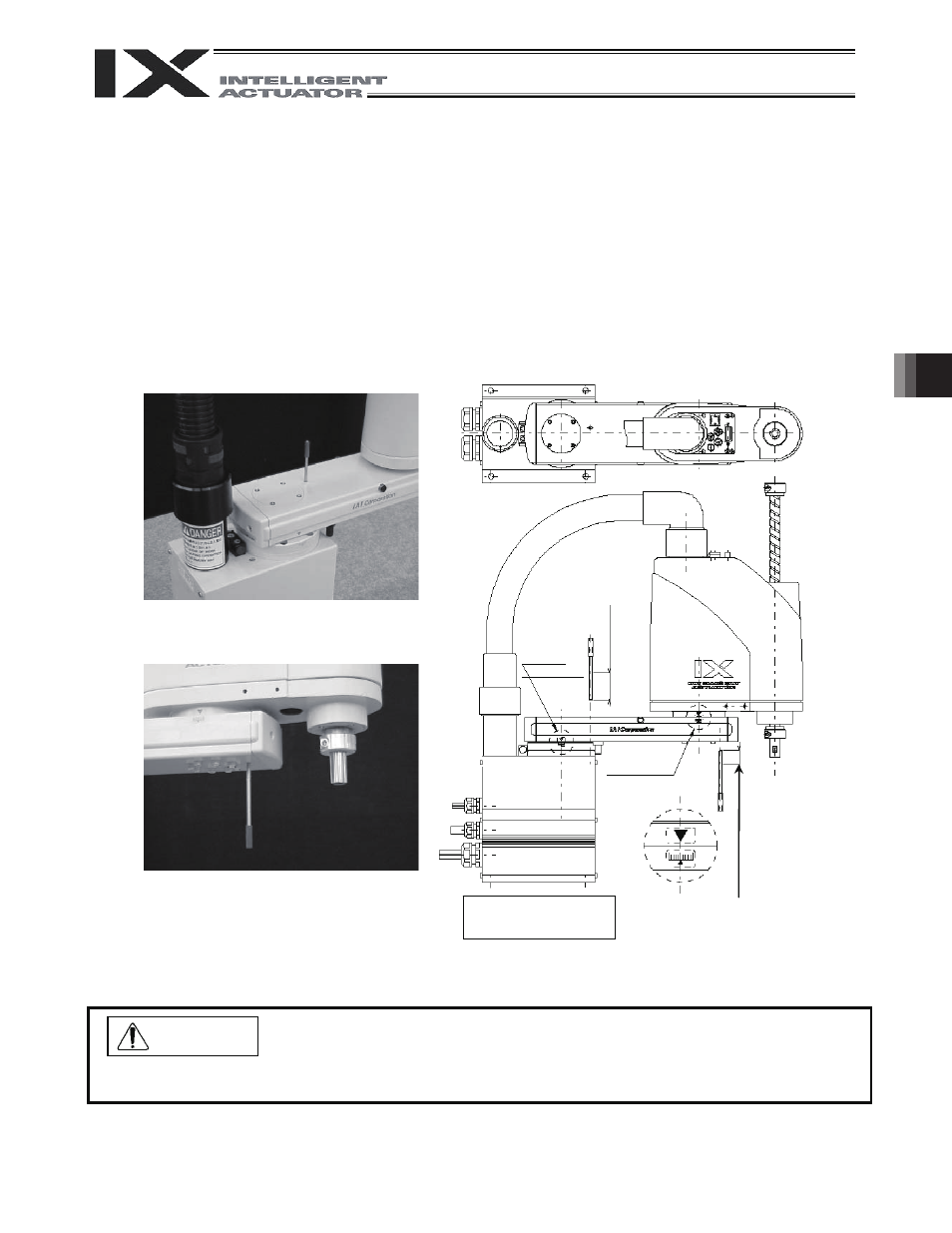

When performing an absolute reset of arm 1, set the adjustment jig (pin) on arm 1 to secure the arm in its

reference position. You can move arm 2 when securing arm 1. When performing an absolute reset of arm 2,

set the adjustment jig (pin) on arm 2 to secure the arm in its reference position. You can move arm 1 when

securing arm 2.

x Set the jig after confirming that the emergency-stop switch is pressed.

x Set the jig after adjusting the arm to the reference position, using the positioning mark label as a guide.

x Arm 1 has a cover (not arm 2), which is fixed with setscrews. Remove the setscrews and detach the

cover before setting the jig.

x It is recommended that an adjustment jig be used to perform an absolute reset. With arm 1 or 2,

however, rotation data can be reset as long as a positioning accuracy of “center of positioning mark label

r1 graduation” is ensured.

z Always press the emergency-stop switch before setting an adjustment jig. Failure to do so may cause the

robot to malfunction and result in a serious accident.

Arm 1

Arm 2

Positioning

mark label

for arm 1

Inser

tion

de

pth

: A

p

pr

o

x

. 60 m

m

Positioning

mark label for

arm 2

Inser

tion

de

pth

: A

p

pr

o

x

. 20 m

m

Illustration of

reference positions

(Note) When performing an absolute reset of arm 1 of the IX-NNN2515,

bend arm 2 slightly as you set the adjustment jig (pin).

Warning