IAI America RCP2CR-SS8C User Manual

Page 63

55

9. Maintenance and Inspection

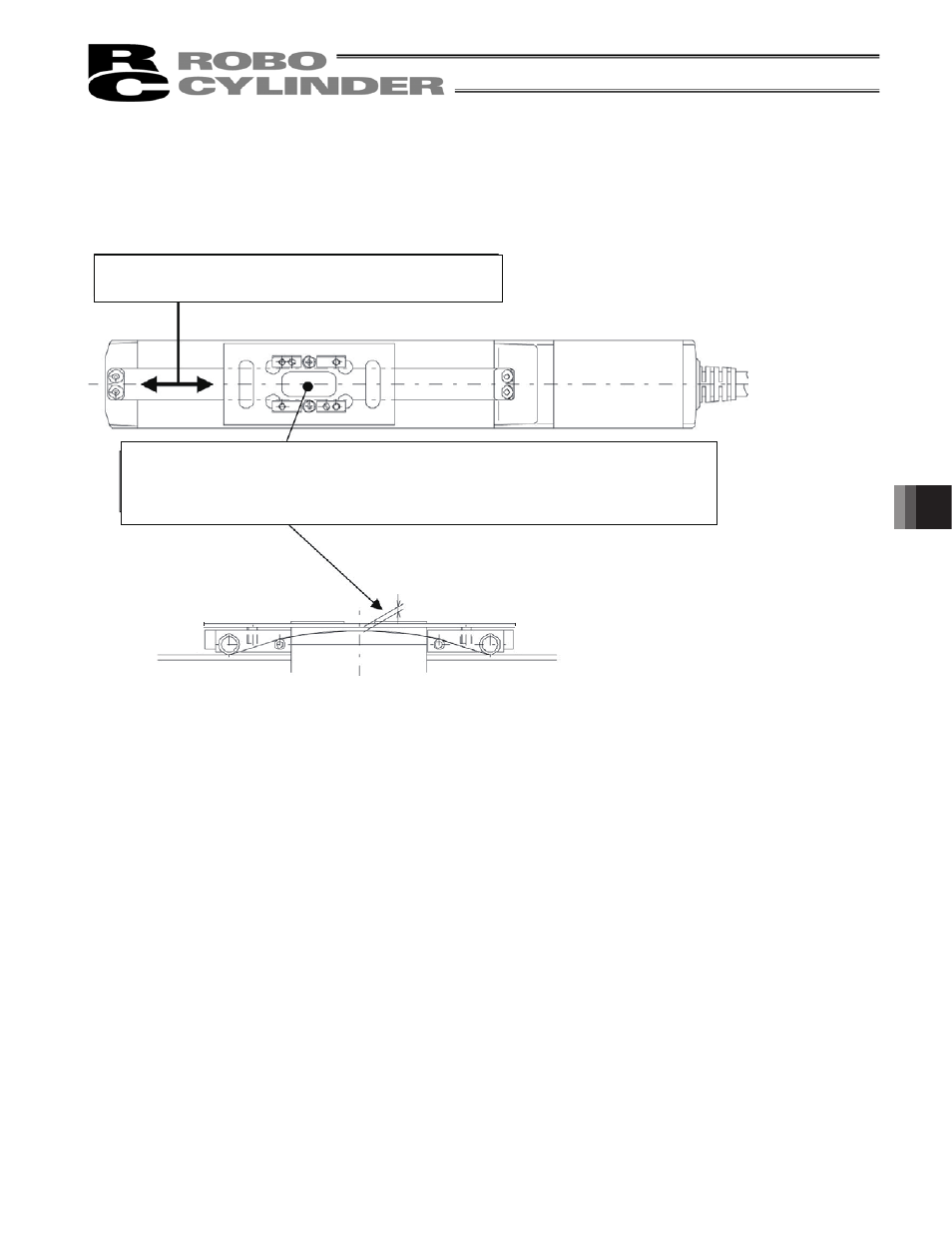

6) Adjust the tension of the stainless sheet.

[1] While looking through the center opening in the clearance-checking tool, move the stainless sheet on the

loose end in the directions of arrows until the clearance between the top face of the stainless sheet and the

back of the clearance-checking tool falls within the specified range.

[2] When the stainless sheet has been properly positioned, tighten the screws on the loose end to a level that the

stainless sheet no longer moves.

Move the stainless sheet in the directions of arrows to

adjust the tension.

While looking through the center opening, check the clearance between the top face

of the stainless sheet and the back of the clearance-checking tool. (If the clearance is

within the specified tolerance range, the tension is appropriate even when the

clearance varies along the entire stroke or between right and left.)

(Standard)

(Cleanroom specification)

SA5C/SA6C: 0.5 ~ 1.0 mm

SA7C:2.0 ~ 3.0 mm (standard)

SA7C: 3.0 ~ 4.0 mm (Cleanroom specification)

Slider roller specification (optional)

SS7C/SS8C/HS8C:0.5 ~ 1.5 mm