Maintenance and inspection, 1 inspection items and schedule, 2 visual inspection of the machine exterior – IAI America RCP2CR-SS8C User Manual

Page 54

46

9. Maintenance and Inspection

9. Maintenance and Inspection

9.1

Inspection Items and Schedule

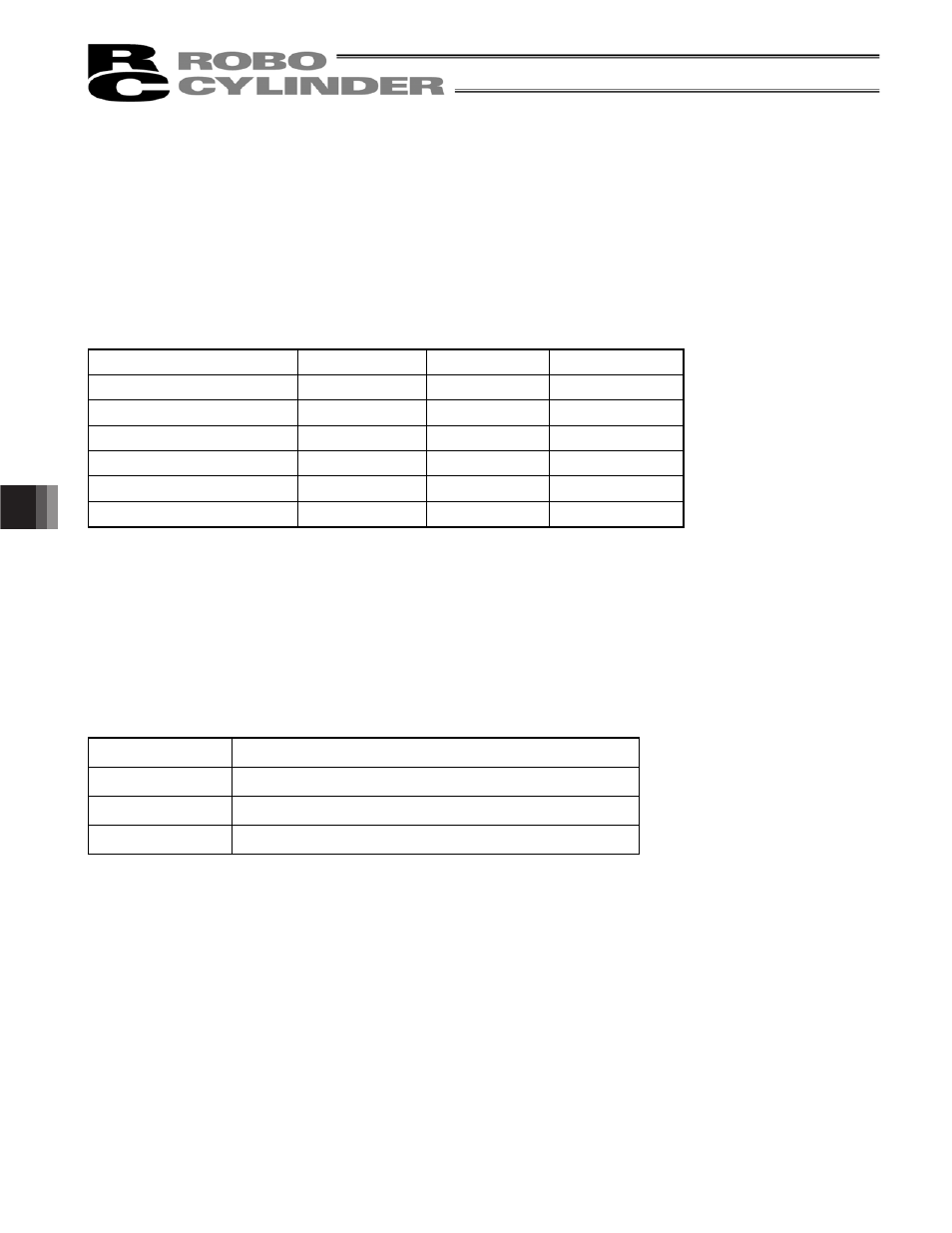

Perform maintenance work according to the schedule below.

The schedule is set assuming eight hours of operation a day. When the operation time is long such as 24-hour

operation, shorten the maintenance intervals as needed.

Visual inspection

Check interior

Grease supply*

2

Start of operation

{

After 1 month of operation

{

After 6 months of operation

{

{

{*

1

After 1 year of operation

{

{

{

Every 6 months thereafter

{

Every 1 year

{

{

{

*1 If grease is found degraded as a result of interior check, add grease.

*2 If continuous back-and-forth operations are performed over a distance of 30 mm or less, grease film may be

broken. As a guide, operate the actuator back and forth five times or so over a distance of

50 mm or more after every 5,000 to 10,000 cycles.

9.2

Visual Inspection of the Machine Exterior

Check the following items when carrying out visual inspection.

Body

Loose mounting bolts?

Cables

Damage to cables or connection to connector box?

Stainless sheet

Damage, foreign deposit or slacks?

General

Unusual noise or vibrations?

,IWKHVWDLQOHVVVKHHWLVVODFNHGPDNHDGMXVWPHQWDVGHHPHGQHFHVVDU\WRUHPRYHWKHVODFNV

$VDURXJKJXLGHWKHVWDLQOHVVVKHHWZill last for 5,000 km of traveled distance.

However, the stainless sheet should be replaced earlier depending on the condition of use.

7KHVWDLQOHVVVKHHWPXVWEHUHSODFHGDWDQ,$,VLWHWKHDFWXDWRUPXVWEHEURXJKWWR,$,RUDWWKHFXVWRPHU¶V

VLWHE\,$,¶VVHUYLFHSHUVRQQHODVDUXOH

,IWKHDFWXDWRULVIL[HGYHUWLFDOO\JUHDVHDSSOLHGto the guide may drip depending on the environment. If this

happens, clean and add grease as necessary.