IAI America RCP2CR-SS8C User Manual

Page 42

34

5. Installation

Slider

Sheet

Right and left clearances

are nearly equal

5.3.2

Using the Mounting Holes on Top of the Base (SA5C, SA6C, SA7C)

Through holes are provided in the base for installing the

actuator on its top face.

When installing the actuator, remove the side covers.

(Remove the two thin-head screws [M3 x 6 mm] for mounting

the cover using an Allen wrench of 1. 5 mm across flats.)

When securing with bolts, protect the stainless sheet from

dents or damage by making sure not to drop bolts or tools

onto the stainless sheet or contact them with it.

As for mounting bolts, use hexagon socket-head bolts conforming to the applicable specification in the table

below in accordance with the machine frame material.

Type

When the mating material is

steel

When the mating material is

aluminum

Mounting Hole (Reference)

SA5C

M4 × 10

M4 × 15

4.5 drill, 8 counterbore depth 4.5

SA6C

M4 × 10

M4 × 15

4.5 drill, 8 counterbore depth 4.5

SA7C

M5 × 10

M4 × 15

6 drill, 9.5 counterbore depth 5.5

Note: When reinstalling the side covers, do not let them contact the end faces of the stainless sheet.

This may damage or bend the stainless sheet, causing the sheet to deteriorate or wear quickly.

Therefore, install the side covers and check for bending according to the procedure below.

[1] To prevent the side covers from contacting the

end faces of the sheet, insert a shim (approx.

0.1 to 0.2 mm) between the sheet and each

cover to provide a slight allowance, and gently

push in the cover.

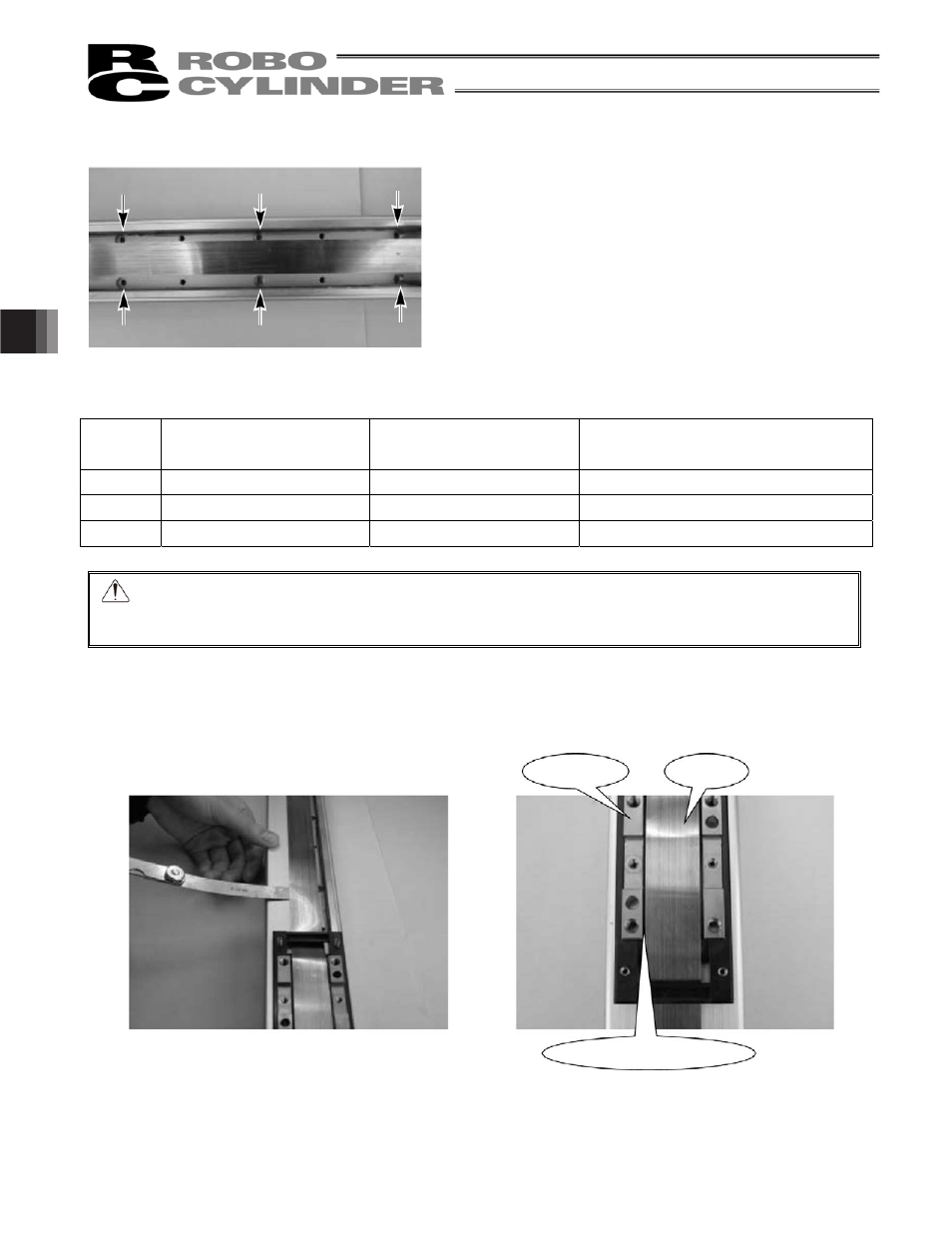

[2] Remove the slider covers and check to see that

the right and left clearances between the slider

and sheet are nearly equal and no bending is

created.

[3] Finally, move the slider back and forth several times along the entire stroke to check that the slider does not

contact the sheet.