FEC AFC1500 User Manual

Page 130

Chapter 7: System Operations

Page 7-16

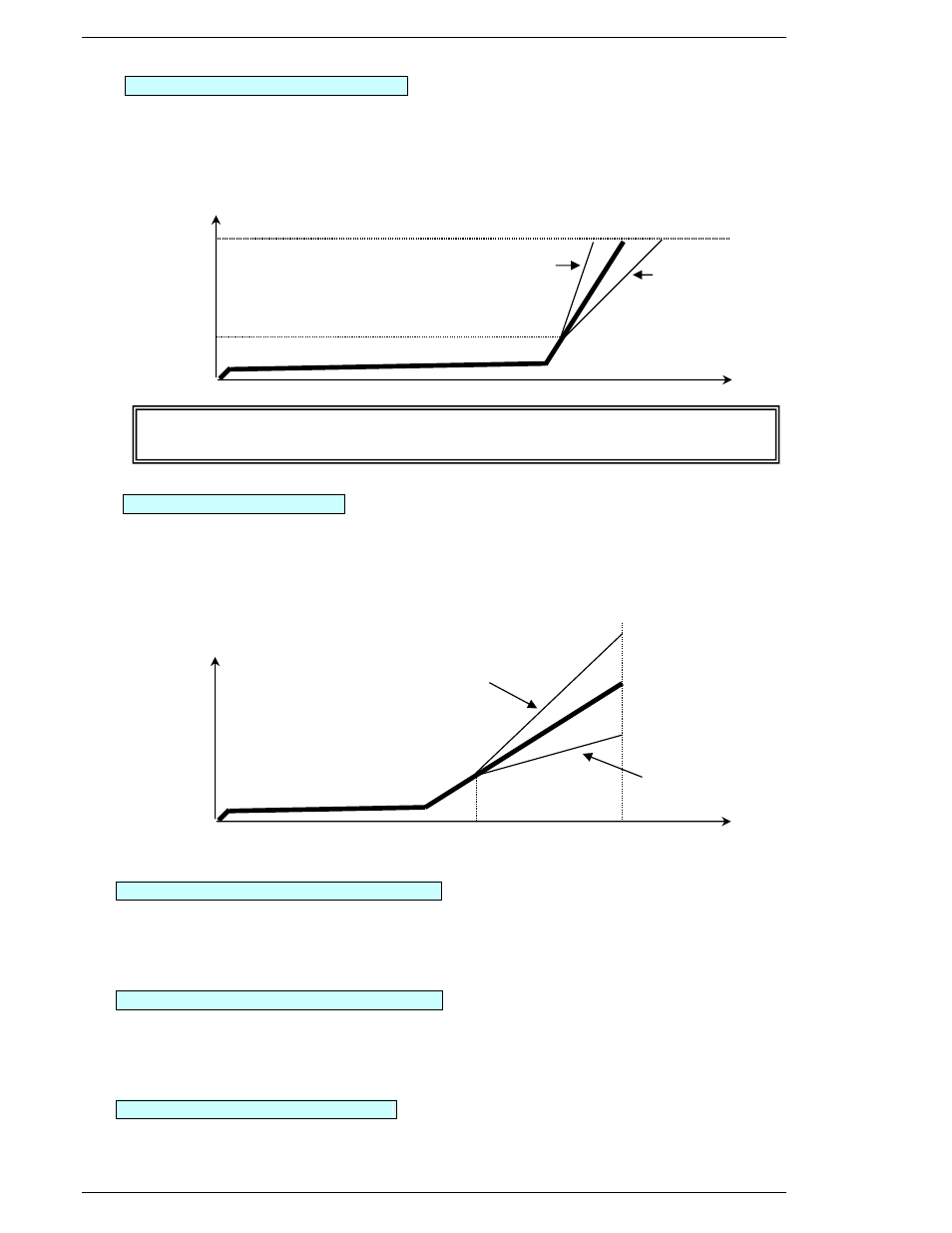

Data No.18 CROS Torque [Nm, Kgm...]

Setting range: 0 ~ [10: Calibration torque] × 1.0

2nd stop / synchronization point for multiple step fastening operations.

End point for 2nd torque rate calculation. [1E: 2

nd

Rate Start Torque is beginning]

Start point for 3

rd

Torque Rate calculation. [Fastening End is the stop point]

Data No.24 CROS Angle [deg] (NOT USED as standard function)

Setting range: 0 ~ 9999

2nd stop / synchronization point for multiple step fastening operations.

End point for 2nd torque rate calculation. [1E: 2

nd

Rate Start Torque or 26: 2

nd

Rate Start Angle

is the beginning]

Start point for 3

rd

Torque Rate calculation. [Fastening End is the stop point]

Data No.19 Torque Inhibit Limit [Nm, Kgm...]

Setting range: 0 ~ [10: Calibration torque] × 1.1

Limit for ignoring the Torque value sensed during Fastening start due to inertia. When the ini-

tial Torque exceeds the Torque Inhibit Limit during [61: Torque Inhibit Revolutions] an

ABNORMAL will be generated and fastening will end.

Data No.1A Offset Torque Limit [Nm, Kgm...]

Setting range: 0 ~ [10: Calibration torque] × 1.1

Maximum value that is acceptable as sensed during an offset check. Offset checking provides

verification that there is not an excess load on the Spindle output drive and provides a refer-

ence value that can be used as a compensation value if Offset Correction is enabled.

Data No.56 Offset Check Speed [rpm]

Setting range: 1 ~ Tool’s maximum rpm.

Speed used to check Offset Torque value.

Angle

Torque

34 Rate 3 Low Limit

35 Rate 3 High Limit

24 CROS

22 Standard

Torque

Angle

13 Standard

18 CROS

34 Rate 3 Low Limit

35 Rate 3 High Limit

If 3rd

t

Torque Rate monitoring is not required, [18:CROS Torque] should be set the same

or higher than [10: Calibration Torque]