5 torque recovery – FEC AFC1500 User Manual

Page 110

Chapter 6: Fastening Instructions

Page 6-24

6.5

Torque Recovery

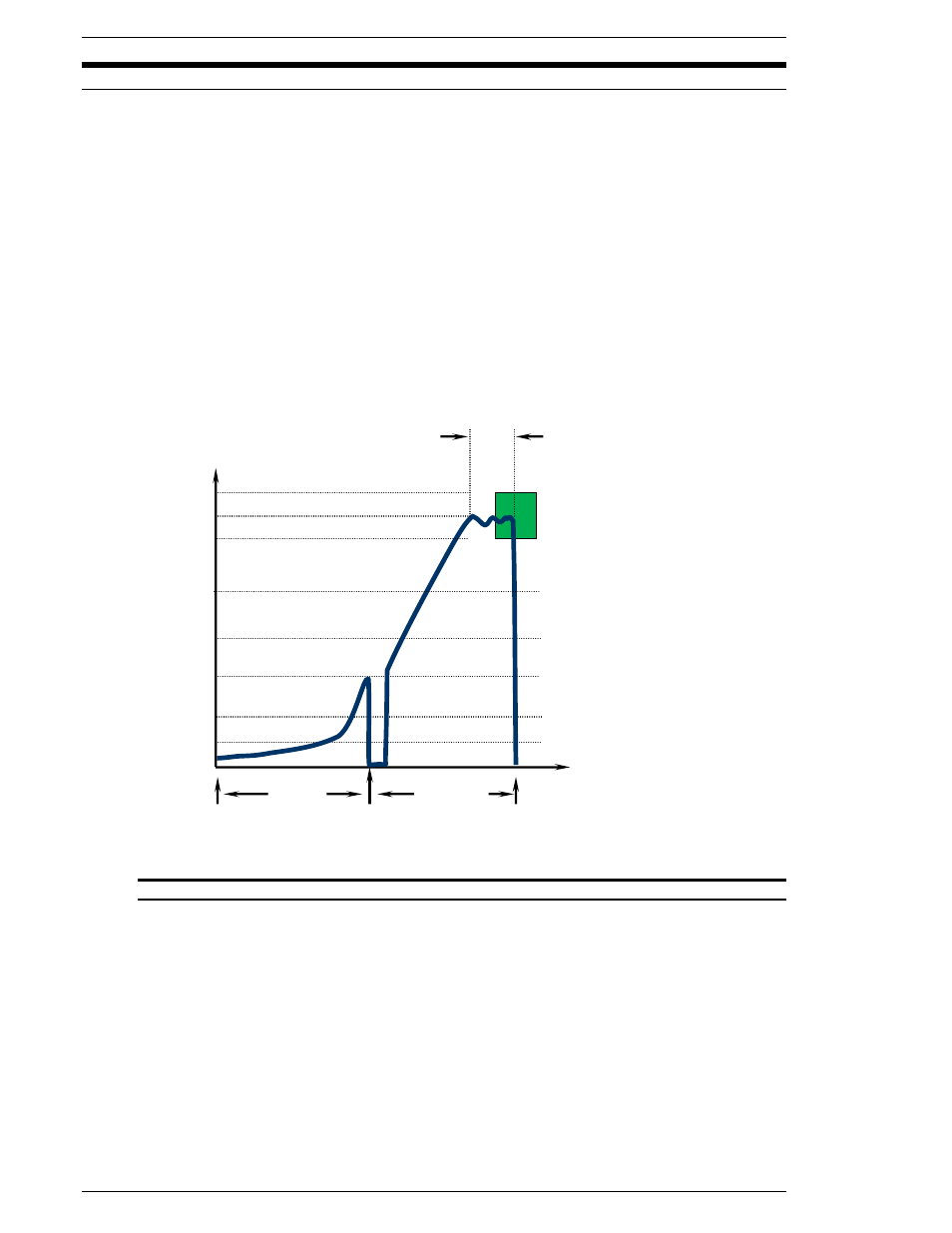

The Torque Recovery function is used when the potential for joint relaxation and interaction exists.

Under this control method, the fasteners are secured to Standard Torque, and then held at a pro-

grammed value for a programmed period of time. This time setting can be between 0.5 - 5.0

seconds. Power is applied to the motor for this duration “holding” torque at the specified STD (Stan-

dard) Torque. During Torque Recovery the tool will use Torque Speed as its maximum Speed, but

will only rotate as a result of a drop in the Torque. Torque Recovery is only available in Torque Con-

trolled Fastening due the fact that the use of Torque Recovery may cause addition rotation (Angle) of

the fastener.

WARNING: The Torque Recovery function will cause the motor to heat up at a rate faster than

normal fastening due to high amperage draw. Particular attention to minimized duty cycle is

recommended if using this function or premature motor failure could result. Torque Recovery

time should be kept to a minimum for the application requirements.

FIG. 6-5 Torque Recovery

Snug Torque

Standard Torque

Threshold Torque

Speed Change Torque

1

st

Torque

Crossover Torque

Torque

Time Only

Peak Torque High Limit

Peak Torque Low Limit

1

st

Time

Final Time

Final Torque High Limit

Final Torque Low Limit

Torque Recovery Time