General installation and grounding tips – GF Signet 2551 Magmeter Flow Sensor - Blind User Manual

Page 5

5

2551 Magmeter

6. General Installation and Grounding Tips

Sensor conditioning

The Magmeter output signal may be unstable immediately after installation. Allowing the sensor to soak in a full pipe (or in any

container of water) for 24 hours will stabilize the performance.

• Very low conductivity À uids may require a longer conditioning period. (The Magmeter will not operate properly in À uids where the

conductivity is less than 20 S/cm.)

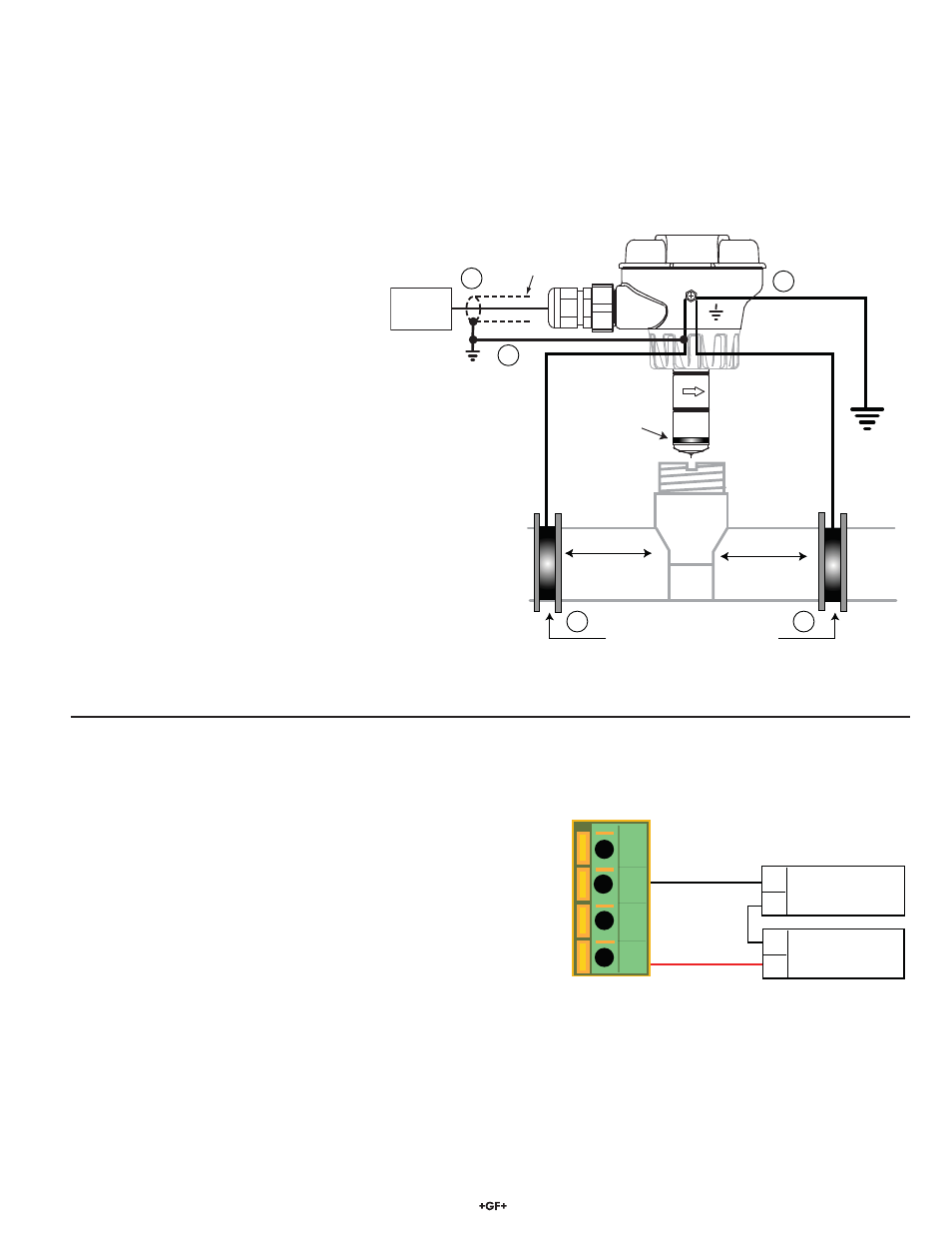

Grounding

The 2551 Magmeter is unaffected by moderate levels of electrical noise. However, in some applications it may be necessary to ground

portions of the system to eliminate electrical interference. The grounding requirements will vary with each installation.

7. Wiring the 2551-XX-12 Magmeter with 4 to 20 mA Loop Output

The 2551-XX-12 Magmeter is a traditional 2-wire passive 4 to 20 mA loop transmitter.

• External loop power (24 VDC ± 10%) is required. See Ordering Information for power supplies.

• The maximum loop resistance the Magmeter can accomodate is 300 ȍ.

• All 2551-XX-12 Magmeters are shipped from the factory with the 4 to 20 mA

output scaled for 0 to 5 m/s (0 to 16.4 ft/s). If this operating range is suitable,

no adjustments are necessary.

• The Calibration Tables on pages 7-10 list the 20 mA setpoint for each

installation ¿ tting. Use this information to program the 4 to 20 mA range of

the loop device (PLC, Datalogger, recorder, etc.)

• The 3-0250 USB to Digital (S

3

L) Con¿ guration/Diagnostic Tool is required to

change the operating range.

Loop + (24 VDC)

Loop - (Ground)

4-20 mA Loop

monitor

(Maximum 300 Ω)

+

+

-

-

24 VDC ± 10%

1

2

3

4

2551 Magmeter

Grounding rings on plastic pipe

(Install between flanges)

or

metal straps on metal pipe

Earth ground

Sensor

Grounding ring

(10 cm to 1.3 m)

(10 cm to 1.3 m)

4 in. to 50 in.

4 in. to 50 in.

Instrument

4.

1.

2.

2.

Do not terminate

shield at Magmeter

3.

d

Install À uid grounding devices immediately upstream and

downstream of the Magmeter.

Connect the À uid grounds to the Earth ground terminal on the 2551.

Use À anged grounding rings or metal electrodes on plastic pipes, or

metal clamps on metal pipes.

Fluid grounds must be in direct contact with the À uid, and as near to

the Magmeter as possible.

e

The shield from the output cable must be terminated at the remote

instrument ONLY.

This shield must be connected at only one end!

f

Connect an additional wire (minimum AWG 14/2.08 mm

2

) from the

remote instrument ground to the Magmeter ground terminal.

One or more of the following steps may be

applied if the 2551 Magmeter is affected by

electrical noise:

c

The ground terminal on the outside of the

yellow housing is connected internally

to the grounding ring at the tip of the

sensor. Connect a wire (14 AWG/2.08 mm

2

recommended) from this terminal directly to a

local Earth ground.